一種多功能智能充電器設計

普通充電器功能單一、針對性強。充電電池種類較多,每一種電池需要配一種充電器,因此用戶經常購置較多的充電器,導致資源浪費,而且普通充電器因為功能不完善或使用不當導致充電電池壽命降低,甚至出現安全事故,廢舊電池對環境會造成很大污染。本文介紹的充電器是基于AVR MEGA16單片機為核心智能控制,利用該單片機內部的A/D采樣電池電壓判斷電池類別,然后通過I/O口控制芯片LM2576實現充電功能。本充電器具有智能判別、智能充電、智能控制的優勢,還加入了反接保護和過充保護功能,充電狀態液晶顯示,充電過程清晰明了,人機交互性能優良。

1 系統硬件(jian)結構

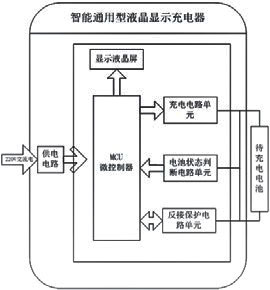

如圖1所示,本系統由供電電路、微處理器、顯示電路、充電電路、電池判斷電路、反接保護電路等6部分構成。以下重點介紹微處理器電路和充電電路。

圖(tu)1 充(chong)電器(qi)系(xi)統(tong)框圖(tu)

1.1 微處理器

微(wei)處理器(qi)采(cai)用(yong)愛特梅(mei)爾半導體(ti)公司(si)的(de)(de)AVR MEGA16型單片機,這是一款(kuan)高性能的(de)(de)8位RISC微(wei)控制(zhi)器(qi)。芯片內部有(you)8位和(he)16位的(de)(de)計數(shu)(shu)器(qi)定時器(qi)(C/T),可作比(bi)較器(qi)、計數(shu)(shu)器(qi)、外部中斷和(he)PWM(也可作A/D)用(yong)于(yu)控制(zhi)輸出。運用(yong)Harvard結構概念,具有(you)預取(qu)指令(ling)的(de)(de)特性,即(ji)對程(cheng)序(xu)存(cun)(cun)儲和(he)數(shu)(shu)據(ju)存(cun)(cun)取(qu)使用(yong)不(bu)同的(de)(de)存(cun)(cun)儲器(qi)和(he)總線。采(cai)用(yong)CMOS工藝(yi)技(ji)術,高速度(50ns)、低功(gong)耗、具有(you)SLEEP(休眠)功(gong)能。

AVR的(de)指令執行速度可達50ns(20MHz)。采用(yong)該芯片的(de)A/D,加一些高(gao)精(jing)密采樣電(dian)阻和(he)旁路電(dian)容組成電(dian)池判(pan)斷電(dian)路。

1.2 充電電路

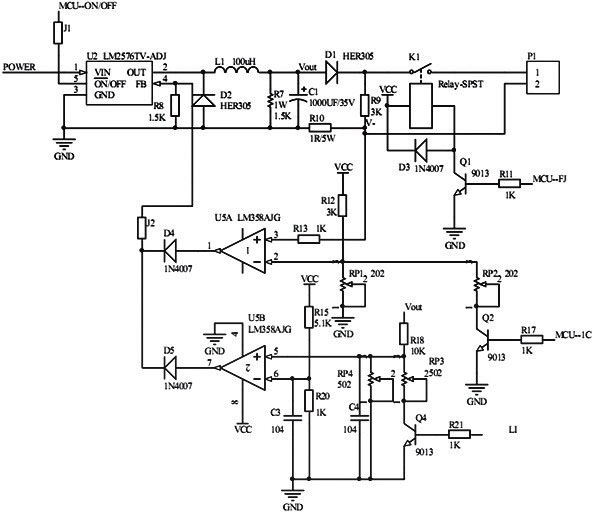

充(chong)電(dian)功(gong)能電(dian)路如(ru)圖2所示。

圖2 充電單元電路(lu)。

圖中由LM358的兩個運算放大器構成的比較電路加上外圍器件構成了充電功能電路。比較器2、RP3、RP4構成電壓控制電路,直接作用于LM2576的反饋端。當電池判斷為NI-MH電池時,RP4構成的基準電路控制輸出電壓為2.86V,當電池判斷為Li電池時單片機控制打開Li口控制,RP3構成的基準電路控制輸出電壓為8.4V.由于LM2576芯片內置了反饋,所以直接改變反饋端口電壓即可改變輸出電壓大小。恒流充電時的恒流是通過限流的方法實現的,電路由比較器1、RP1、RP2構成。比較器1與比較器2基本原理相同,只是在輸出端口通過功率電阻將電流轉換為電壓進行控制,通過對電壓的控制實現對電流的限制,從而達到恒流的目的。脈沖式恒流充電電流實現是通過單片機每隔一定時間打開MCU--1C端口,當MCU--1C端口為高低電平時,輸出電流變0.3C,MCU--1C端口為低電平時,輸出電流為0.1C,從而實現電流交替變化達到脈沖式恒流的目標。如(ru)圖3所示。

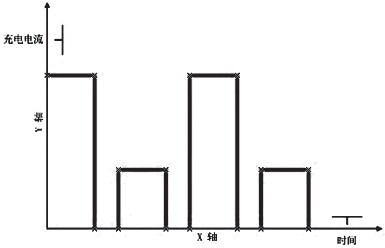

圖3 恒流脈沖式充電(dian)電(dian)流變化圖。

由圖3可以看出,脈沖(chong)式恒流充(chong)電(dian)電(dian)流不是單(dan)一(yi)的(de)(de)0.3C或者單(dan)一(yi)的(de)(de)0.1C,而是以脈沖(chong)的(de)(de)交替方式進(jin)行充(chong)電(dian)。

這樣可以對電池(chi)(chi)起到最大的(de)保護(hu)作用(yong),延長電池(chi)(chi)的(de)使用(yong)壽命。

1.3 電池判斷與極性檢測

(1)電池判(pan)斷原理。

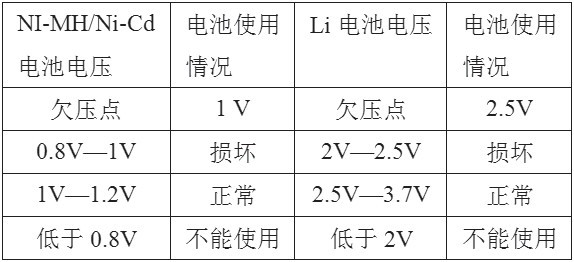

表1 電池使用時電壓變化表

如表1 所示,我們日常生活實際使用的電池為NI-MH/Ni-Cd、LI電池三種,其中NI-MH/Ni-Cd電池充電方式相同,所以歸為一類。單節NI-MH/Ni-Cd電池電壓為1.2V,欠壓點為1V,當使用時電壓低于1V時電池已經不能正常使用。當電池電壓下降為0.8~1V時電池已經接近損壞需要啟動修復充電;單節LI電池電壓為3.7V,欠壓點為2.5V,當使用中電壓低于2.5V時電池已經不能正常使用。當電池電壓下降為2~2.5V時電池已經接近損壞,需要啟動修復充電。所以根據兩種電池特性我們設計當電池電壓為0.6~4V時為NI-MH/Ni-Cd電池,當電池電壓為4~9V時為LI電池。

(2)反接(jie)保護原理(li)。

在(zai)輸(shu)(shu)出(chu)口(kou)正負(fu)端(duan)(duan)各(ge)接(jie)有一(yi)個光(guang)耦(ou)(ou)(ou),電(dian)池(chi)沒(mei)有接(jie)入時光(guang)耦(ou)(ou)(ou)傳(chuan)回(hui)(hui)(hui)的(de)信(xin)號為兩(liang)個低電(dian)平,當(dang)(dang)有電(dian)池(chi)接(jie)入時其中一(yi)個光(guang)耦(ou)(ou)(ou)傳(chuan)回(hui)(hui)(hui)的(de)信(xin)號為高電(dian)平。當(dang)(dang)電(dian)池(chi)正接(jie)時輸(shu)(shu)出(chu)端(duan)(duan)口(kou)正端(duan)(duan)的(de)光(guang)耦(ou)(ou)(ou)傳(chuan)回(hui)(hui)(hui)的(de)信(xin)號為高電(dian)平,負(fu)端(duan)(duan)口(kou)傳(chuan)回(hui)(hui)(hui)的(de)信(xin)號為低電(dian)平。當(dang)(dang)電(dian)池(chi)反接(jie)時,輸(shu)(shu)出(chu)端(duan)(duan)口(kou)負(fu)端(duan)(duan)的(de)光(guang)耦(ou)(ou)(ou)傳(chuan)回(hui)(hui)(hui)的(de)信(xin)號為高電(dian)平,輸(shu)(shu)出(chu)端(duan)(duan)口(kou)正端(duan)(duan)傳(chuan)回(hui)(hui)(hui)信(xin)號為高電(dian)平。MCU通過判斷光(guang)耦(ou)(ou)(ou)傳(chuan)回(hui)(hui)(hui)的(de)電(dian)平高低就可以(yi)判斷電(dian)池(chi)接(jie)入與否以(yi)及電(dian)池(chi)是否反接(jie)。

2 系統(tong)軟件介紹

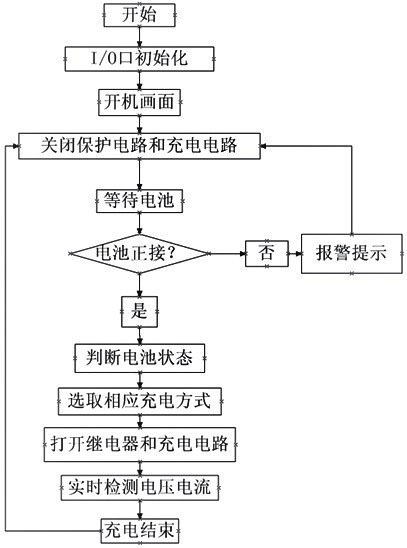

圖(tu)4 軟件程序流(liu)程圖(tu)。

圖4清晰地展現(xian)了(le)主程(cheng)序(xu)的(de)流程(cheng),首先開(kai)機后(hou)對(dui)所(suo)有使用(yong)到的(de)I/O口進(jin)(jin)行(xing)初始化,包括內(nei)置ADC電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)的(de)初始化和(he)其他寄存器(qi)的(de)初始化。然(ran)后(hou)顯示開(kai)機畫面,開(kai)機默認關(guan)閉反(fan)(fan)(fan)接(jie)保(bao)護(hu)電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)和(he)充(chong)(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu),然(ran)后(hou)進(jin)(jin)入(ru)等待(dai)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)狀態(tai)(tai)。電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)接(jie)入(ru),如(ru)果電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)反(fan)(fan)(fan)接(jie),蜂鳴器(qi)報警,不(bu)打(da)開(kai)反(fan)(fan)(fan)接(jie)保(bao)護(hu),電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)正接(jie),打(da)開(kai)反(fan)(fan)(fan)接(jie)保(bao)護(hu)電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)和(he)充(chong)(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu),然(ran)后(hou)進(jin)(jin)入(ru)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)狀態(tai)(tai)判斷(duan)程(cheng)序(xu),根(gen)據狀態(tai)(tai)選(xuan)取(qu)相(xiang)應(ying)的(de)充(chong)(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)方式,控制充(chong)(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)進(jin)(jin)行(xing)充(chong)(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian),由電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)電(dian)(dian)(dian)(dian)(dian)(dian)流采集電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)實時(shi)對(dui)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)狀態(tai)(tai)進(jin)(jin)行(xing)采集.在收集到的(de)信息反(fan)(fan)(fan)映出電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)快充(chong)(chong)(chong)(chong)滿(man)時(shi),用(yong)涓流充(chong)(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)一(yi)段(duan)時(shi)間后(hou),關(guan)閉充(chong)(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)防止(zhi)過充(chong)(chong)(chong)(chong)。整個主程(cheng)序(xu)脈絡清晰,配合(he)硬(ying)件電(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)完全實現(xian)了(le)充(chong)(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)器(qi)的(de)所(suo)有功能。

智能通用型液晶顯示充電器功能完善、設計新穎,解決了傳統充電器功能單一使用不方便的問題,能延長充電電池使用壽命,具有廣闊的市場前景。