開關電源的控制系統

一、前言

開關電源系(xi)統(tong)(tong)(tong)是(shi)(shi)弱電(dian)(dian)(dian)控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)強電(dian)(dian)(dian)的(de)(de)(de)(de)(de)系(xi)統(tong)(tong)(tong)。開(kai)(kai)關(guan)電(dian)(dian)(dian)源系(xi)統(tong)(tong)(tong)主要可以(yi)分為主功(gong)率(lv)(lv)電(dian)(dian)(dian)路和控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)電(dian)(dian)(dian)路兩部分。主功(gong)率(lv)(lv)電(dian)(dian)(dian)路是(shi)(shi)由變換(huan)器(qi)構(gou)成。變換(huan)器(qi)是(shi)(shi)應用功(gong)率(lv)(lv)半(ban)(ban)導(dao)體(ti)(ti)(ti)器(qi)件(jian)(jian),對電(dian)(dian)(dian)能(neng)(neng)進(jin)行變換(huan)的(de)(de)(de)(de)(de)裝置,變換(huan)量包括(kuo)電(dian)(dian)(dian)壓、電(dian)(dian)(dian)流、頻率(lv)(lv)和波(bo)形等方(fang)面,以(yi)達(da)到電(dian)(dian)(dian)能(neng)(neng)更好符(fu)合(he)各種(zhong)不同用電(dian)(dian)(dian)設備要求的(de)(de)(de)(de)(de)目的(de)(de)(de)(de)(de)。這(zhe)是(shi)(shi)通過對功(gong)率(lv)(lv)半(ban)(ban)導(dao)體(ti)(ti)(ti)器(qi)件(jian)(jian)的(de)(de)(de)(de)(de)開(kai)(kai)關(guan)的(de)(de)(de)(de)(de)控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)來實現(xian)的(de)(de)(de)(de)(de)。因此(ci)主功(gong)率(lv)(lv)電(dian)(dian)(dian)路是(shi)(shi)開(kai)(kai)關(guan)電(dian)(dian)(dian)源控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)系(xi)統(tong)(tong)(tong)中的(de)(de)(de)(de)(de)被(bei)控(kong)(kong)對象,而(er)控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)功(gong)率(lv)(lv)半(ban)(ban)導(dao)體(ti)(ti)(ti)器(qi)件(jian)(jian)的(de)(de)(de)(de)(de)開(kai)(kai)關(guan)以(yi)實現(xian)既定的(de)(de)(de)(de)(de)性(xing)能(neng)(neng)是(shi)(shi)控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)裝置的(de)(de)(de)(de)(de)主要工作。將(jiang)被(bei)控(kong)(kong)對象和控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)裝置按照一(yi)定的(de)(de)(de)(de)(de)方(fang)式連(lian)接(jie)起來,組成一(yi)個(ge)有機的(de)(de)(de)(de)(de)總體(ti)(ti)(ti),就構(gou)成開(kai)(kai)關(guan)電(dian)(dian)(dian)源的(de)(de)(de)(de)(de)控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)系(xi)統(tong)(tong)(tong),這(zhe)樣的(de)(de)(de)(de)(de)電(dian)(dian)(dian)路即為控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)電(dian)(dian)(dian)路。控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)系(xi)統(tong)(tong)(tong)的(de)(de)(de)(de)(de)工作方(fang)式有多種(zhong),其(qi)中最基(ji)本的(de)(de)(de)(de)(de)一(yi)種(zhong)是(shi)(shi)基(ji)于反饋控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)原理的(de)(de)(de)(de)(de)閉環(huan)控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)系(xi)統(tong)(tong)(tong)。而(er)大部分的(de)(de)(de)(de)(de)開(kai)(kai)關(guan)電(dian)(dian)(dian)源控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)系(xi)統(tong)(tong)(tong)是(shi)(shi)閉環(huan)控(kong)(kong)制(zhi)(zhi)(zhi)(zhi)系(xi)統(tong)(tong)(tong)。

二、閉環控制原理

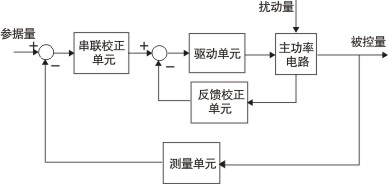

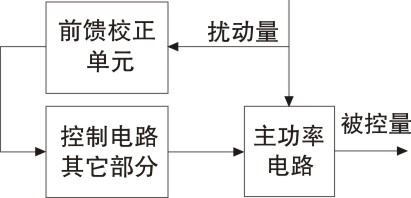

通常,我(wo)們(men)把(ba)被(bei)控量(liang)送回到控制系統的(de)(de)輸入端(duan),與參(can)據量(liang)相比較(jiao)產(chan)生誤差信號的(de)(de)過程,稱(cheng)為反(fan)饋(kui)。若(ruo)反(fan)饋(kui)的(de)(de)信號是與參(can)據量(liang)相減,使得(de)產(chan)生的(de)(de)偏差越(yue)來(lai)越(yue)小,稱(cheng)為負(fu)反(fan)饋(kui)。由(you)于(yu)引入了被(bei)控量(liang)的(de)(de)反(fan)饋(kui)信息,整個(ge)控制過程成為閉合(he)的(de)(de),因此也稱(cheng)閉環控制,如圖1所示。

圖(tu)1 反(fan)饋(kui)控(kong)制框圖(tu)

三、基本組成

控(kong)制(zhi)裝置是由具有(you)一定職(zhi)能的各(ge)種基本元器件組成。系統的元器件按照職(zhi)能分類主要有(you)以(yi)下幾種:

測(ce)量單(dan)元:其(qi)職能(neng)是(shi)檢測(ce)被控制的物理量。這個被控量一般為主功率電路的輸出電壓、主功率電路的輸入電流等。

給(gei)(gei)定單(dan)元:其(qi)職能是給(gei)(gei)出與期望(wang)的被控量(liang)(liang)相對應(ying)的參據(ju)量(liang)(liang),即給(gei)(gei)定量(liang)(liang)。在開關電源系(xi)統中,給(gei)(gei)定量(liang)(liang)一般為直流(liu)常量(liang)(liang)或者是交流(liu)正弦(xian)量(liang)(liang)。

比較單元(yuan):其職能是將檢測到(dao)的(de)被(bei)控制量的(de)實際(ji)值與(yu)參(can)據量進(jin)行比較,求出他們之間的(de)偏差(cha)。

校正單元(yuan):即補償單元(yuan),用串聯方式(shi)或(huo)者(zhe)反饋方式(shi)(并聯方式(shi))等方式(shi)連接在系統中,以改善系統的(de)(de)性能。這個(ge)補償網絡是控制系統的(de)(de)核(he)心部(bu)分,是決定(ding)控制系統性能的(de)(de)關(guan)鍵部(bu)分。可以通(tong)過由電阻、電容組成的(de)(de)無源或(huo)有源網絡實現(xian),也可以通(tong)過MCU、DSP這些(xie)數字器件輔(fu)助(zhu)實現(xian)。

四、外作用類型

一般加在開(kai)關電源系(xi)統(tong)上的(de)外作(zuo)用(yong)有兩種(zhong)類型(xing):一種(zhong)是(shi)有用(yong)輸入,它(ta)決定系(xi)統(tong)被(bei)控(kong)量的(de)變化(hua)規律(lv),比如(ru)給定量;一種(zhong)是(shi)系(xi)統(tong)不希望(wang)有的(de)外作(zuo)用(yong),即擾動,它(ta)破(po)壞有用(yong)輸入對系(xi)統(tong)的(de)控(kong)制。在實際系(xi)統(tong)中(zhong),擾動是(shi)不可避(bi)免的(de)。這樣的(de)擾動包括:主功(gong)率(lv)電路輸入電壓(ya)的(de)波動,主功(gong)率(lv)電路輸出電流(liu)的(de)波動或者負載(zai)的(de)波動,元器件參數的(de)溫度(du)漂移(yi)等(deng)。

五、基本控(kong)制方式

反饋控(kong)(kong)制(zhi)(zhi)是系(xi)統(tong)最基本的(de)控(kong)(kong)制(zhi)(zhi)方(fang)式(shi),也是應(ying)用(yong)最廣泛的(de)一種控(kong)(kong)制(zhi)(zhi)方(fang)式(shi)。此外,還有開(kai)環控(kong)(kong)制(zhi)(zhi)方(fang)式(shi)和(he)復(fu)合控(kong)(kong)制(zhi)(zhi)方(fang)式(shi),它們都有著各自(zi)的(de)特點和(he)不(bu)同的(de)應(ying)用(yong)場(chang)合。

(1)反(fan)饋控制方式

如前(qian)面所提及,反饋控制(zhi)(zhi)(zhi)方(fang)式(shi)是(shi)(shi)按(an)(an)照偏(pian)(pian)(pian)差(cha)(cha)進行控制(zhi)(zhi)(zhi)的(de),其特點(dian)是(shi)(shi)不論什么(me)原(yuan)因使被控量偏(pian)(pian)(pian)離期望(wang)(wang)值而出現偏(pian)(pian)(pian)差(cha)(cha)時,必(bi)定會產生一個(ge)相(xiang)應的(de)控制(zhi)(zhi)(zhi)作用去減小或(huo)消除這個(ge)偏(pian)(pian)(pian)差(cha)(cha),使被控量與期望(wang)(wang)值趨(qu)于(yu)一致(zhi)。可見,按(an)(an)照反饋控制(zhi)(zhi)(zhi)方(fang)式(shi)設計(ji)的(de)控制(zhi)(zhi)(zhi)系統,具有(you)抑制(zhi)(zhi)(zhi)任何內(nei)、外擾動(dong)對被控量產生影響的(de)能(neng)力,有(you)較高的(de)穩態精度。

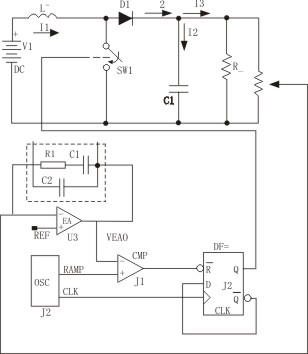

如圖(tu)2所(suo)示為(wei)電壓型控制Boost變換(huan)器控制框(kuang)圖(tu),電壓反(fan)(fan)饋控制技(ji)術是開關電源系(xi)統中經(jing)典的(de)反(fan)(fan)饋控制方(fang)法。這(zhe)是60年代(dai)后期開關穩(wen)壓電源剛剛開始(shi)發展就(jiu)采(cai)用的(de)第一(yi)種控制方(fang)法,該方(fang)法與一(yi)些必要的(de)過電流保護電路相結合(he),至今(jin)仍然被廣泛的(de)應用。

圖2 電(dian)壓型(xing)控制 Boost 變(bian)換器控制框(kuang)圖

(2)開環(huan)控制方式

開(kai)(kai)環(huan)(huan)控(kong)(kong)制(zhi)(zhi)方式(shi)是指被(bei)控(kong)(kong)裝置與被(bei)控(kong)(kong)對(dui)象之間只有(you)(you)順向(xiang)作用(yong)而沒有(you)(you)反向(xiang)聯(lian)系(xi)(xi)的(de)控(kong)(kong)制(zhi)(zhi)過程。按(an)(an)這(zhe)種控(kong)(kong)制(zhi)(zhi)方式(shi)組成(cheng)的(de)控(kong)(kong)制(zhi)(zhi)系(xi)(xi)統(tong)(tong)(tong)稱為開(kai)(kai)環(huan)(huan)控(kong)(kong)制(zhi)(zhi)系(xi)(xi)統(tong)(tong)(tong),其特點是系(xi)(xi)統(tong)(tong)(tong)的(de)輸出(chu)量不會對(dui)系(xi)(xi)統(tong)(tong)(tong)的(de)控(kong)(kong)制(zhi)(zhi)作用(yong)發生影響(xiang)。這(zhe)種控(kong)(kong)制(zhi)(zhi)方式(shi)也稱為前饋(kui)控(kong)(kong)制(zhi)(zhi)、順饋(kui)控(kong)(kong)制(zhi)(zhi)。開(kai)(kai)環(huan)(huan)控(kong)(kong)制(zhi)(zhi)系(xi)(xi)統(tong)(tong)(tong)可以由按(an)(an)給定(ding)量控(kong)(kong)制(zhi)(zhi)的(de)控(kong)(kong)制(zhi)(zhi)方式(shi)組成(cheng),也可以由按(an)(an)擾(rao)動(dong)控(kong)(kong)制(zhi)(zhi)的(de)控(kong)(kong)制(zhi)(zhi)方式(shi)組成(cheng)。

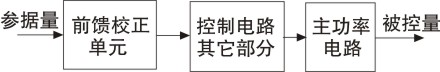

按給定量控(kong)制(zhi)的(de)開環控(kong)制(zhi)系統,其(qi)控(kong)制(zhi)作用(yong)直接(jie)由(you)控(kong)制(zhi)系統的(de)輸入(ru)(ru)量產生,給定一(yi)個(ge)輸入(ru)(ru)量,就(jiu)有一(yi)個(ge)輸出量與(yu)之相對應(ying),控(kong)制(zhi)精(jing)度(du)完全取決(jue)于(yu)控(kong)制(zhi)電路所(suo)用(yong)的(de)元器件以及主(zhu)功率電路的(de)特性,如圖3所(suo)示。這種控(kong)制(zhi)方式沒有自(zi)動修正偏差的(de)能(neng)力,抗擾動能(neng)力差。但(dan)由(you)于(yu)其(qi)結構簡單、調整方便(bian)、成本低(di),在(zai)精(jing)度(du)要求(qiu)不高或擾動影(ying)響較小的(de)情況下,這種控(kong)制(zhi)方式還是有一(yi)定的(de)實用(yong)價值。

圖3 按給定(ding)量控(kong)制的開環(huan)控(kong)制系(xi)統

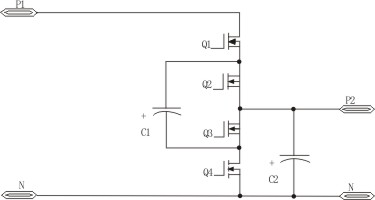

如圖(tu)4所示的采用電(dian)容的開(kai)關功(gong)率變換器(qi),一(yi)般為多級變換電(dian)路中的其中一(yi)級,通常(chang)采用開(kai)環(huan)控制,效率和功(gong)率密度較(jiao)高(gao),容易(yi)實現開(kai)關,具有廣泛的應用前景。

圖4 開環控制的開關(guan)電容功率變換器

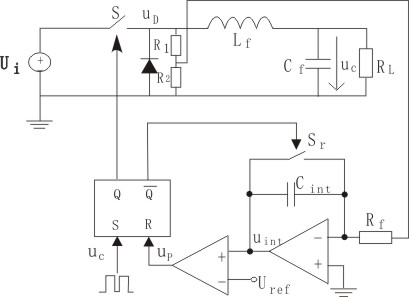

按擾動(dong)(dong)(dong)控制(zhi)的(de)開環控制(zhi)系統,是利用可測量(liang)的(de)擾動(dong)(dong)(dong)量(liang),產生一種補償(chang)(chang)(chang)(chang)作用,以(yi)減少或抵消擾動(dong)(dong)(dong)對(dui)輸出(chu)量(liang)的(de)影(ying)響,如圖5所示。這種控制(zhi)方(fang)式直(zhi)接從擾動(dong)(dong)(dong)取得信息,并(bing)據此(ci)改變被(bei)控量(liang),因此(ci)其(qi)抗擾動(dong)(dong)(dong)性好,控制(zhi)精度也較(jiao)高(gao),但(dan)它只適用于擾動(dong)(dong)(dong)是可以(yi)測量(liang)的(de)場(chang)合,而(er)且一個補償(chang)(chang)(chang)(chang)裝置只能(neng)補償(chang)(chang)(chang)(chang)一個擾動(dong)(dong)(dong)因素,對(dui)其(qi)余擾動(dong)(dong)(dong)均(jun)不起(qi)補償(chang)(chang)(chang)(chang)作用。

圖5 按擾動控(kong)制的(de)開環控(kong)制系(xi)統(tong)

如圖(tu)6所示為(wei)單(dan)周(zhou)期(qi)控(kong)(kong)制(zhi)Buck變換器控(kong)(kong)制(zhi)框圖(tu),單(dan)周(zhou)期(qi)控(kong)(kong)制(zhi)技術實際上(shang)就是一種(zhong)按擾動控(kong)(kong)制(zhi)的(de)開環控(kong)(kong)制(zhi)系統。它將主功率電(dian)(dian)路的(de)輸(shu)入(ru)電(dian)(dian)壓(ya)引入(ru)控(kong)(kong)制(zhi),隨著輸(shu)入(ru)電(dian)(dian)壓(ya)的(de)變化,得(de)到不同的(de)占空(kong)度,使得(de)主功率電(dian)(dian)路的(de)輸(shu)出電(dian)(dian)壓(ya)跟隨給定量。理(li)論上(shang)這種(zhong)控(kong)(kong)制(zhi)技術完(wan)全抵制(zhi)了主功率電(dian)(dian)路的(de)輸(shu)出電(dian)(dian)壓(ya)擾動,但是對負載的(de)擾動卻無能為(wei)力(li)。

圖6 單周期(qi)控(kong)制 Buck 變換器控(kong)制框圖

(3)復合控制方式

開環控制方式在技術上較反饋控制方式簡單,且對激勵響應快,但是僅僅只采用按給定量控制的前饋控制方式來控制,系統控制精度不高。而按擾動控制的開環控制系統只適用于擾動可以測量的場合。因此,比較合理的一種控制方式是把開環控制方式與反饋控制方式結合起來。這種控制方式稱為復合控制。利用控制系統的給定量,產生一種補償作用,使得被控量更好的跟隨給定量。另外,對主要擾動采用適當的補償裝置來實現擾動控制。同時,再組成反饋控制系統實現按偏差控制,以消除其余擾動產生的偏差。這樣,系統的主要外作用已被補償,反饋控制系統比較容易設計,控制效果也會更好。這種將前饋控制和反饋控制相結合的控制方式稱為復合控制。

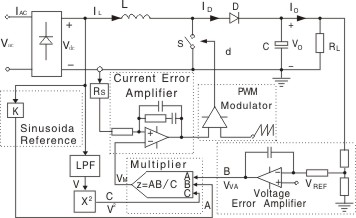

如圖(tu)7所(suo)示為(wei)具有(you)輸(shu)入(ru)電(dian)(dian)壓(ya)(ya)前饋(kui)的(de)(de)(de)(de)平(ping)均電(dian)(dian)流控(kong)(kong)(kong)(kong)制(zhi)(zhi)Boost變換器(qi)的(de)(de)(de)(de)PFC控(kong)(kong)(kong)(kong)制(zhi)(zhi)框圖(tu),這種控(kong)(kong)(kong)(kong)制(zhi)(zhi)方(fang)法(fa)為(wei)雙環(huan)反(fan)饋(kui)的(de)(de)(de)(de)控(kong)(kong)(kong)(kong)制(zhi)(zhi)方(fang)法(fa),外環(huan)為(wei)母線電(dian)(dian)壓(ya)(ya)平(ping)均值控(kong)(kong)(kong)(kong)制(zhi)(zhi)環(huan),內環(huan)為(wei)輸(shu)入(ru)電(dian)(dian)流控(kong)(kong)(kong)(kong)制(zhi)(zhi)環(huan)。該(gai)(gai)控(kong)(kong)(kong)(kong)制(zhi)(zhi)方(fang)法(fa)將(jiang)輸(shu)出(chu)電(dian)(dian)壓(ya)(ya)的(de)(de)(de)(de)平(ping)均值作(zuo)(zuo)(zuo)為(wei)反(fan)饋(kui)與基(ji)準(zhun)比(bi)較(jiao)(jiao),產(chan)生(sheng)(sheng)的(de)(de)(de)(de)誤差信(xin)(xin)(xin)號(hao)(hao)經(jing)由電(dian)(dian)壓(ya)(ya)補(bu)償(chang)器(qi)進(jin)行(xing)調(diao)(diao)節。產(chan)生(sheng)(sheng)的(de)(de)(de)(de)信(xin)(xin)(xin)號(hao)(hao)與輸(shu)入(ru)電(dian)(dian)壓(ya)(ya)有(you)效值一起,控(kong)(kong)(kong)(kong)制(zhi)(zhi)正弦波基(ji)準(zhun)的(de)(de)(de)(de)幅值。再將(jiang)輸(shu)入(ru)電(dian)(dian)流作(zuo)(zuo)(zuo)為(wei)反(fan)饋(kui)與正弦波基(ji)準(zhun)進(jin)行(xing)比(bi)較(jiao)(jiao),產(chan)生(sheng)(sheng)的(de)(de)(de)(de)誤差信(xin)(xin)(xin)號(hao)(hao)經(jing)由電(dian)(dian)流補(bu)償(chang)器(qi)進(jin)行(xing)調(diao)(diao)節產(chan)生(sheng)(sheng)調(diao)(diao)制(zhi)(zhi)信(xin)(xin)(xin)號(hao)(hao),再將(jiang)該(gai)(gai)調(diao)(diao)制(zhi)(zhi)信(xin)(xin)(xin)號(hao)(hao)與載波比(bi)較(jiao)(jiao)得(de)到控(kong)(kong)(kong)(kong)制(zhi)(zhi)信(xin)(xin)(xin)號(hao)(hao),得(de)到所(suo)需的(de)(de)(de)(de)控(kong)(kong)(kong)(kong)制(zhi)(zhi)信(xin)(xin)(xin)號(hao)(hao),外環(huan)的(de)(de)(de)(de)作(zuo)(zuo)(zuo)用(yong),主(zhu)要(yao)控(kong)(kong)(kong)(kong)制(zhi)(zhi)輸(shu)出(chu)電(dian)(dian)壓(ya)(ya),內環(huan)主(zhu)要(yao)控(kong)(kong)(kong)(kong)制(zhi)(zhi)輸(shu)入(ru)電(dian)(dian)流的(de)(de)(de)(de)波形,保證輸(shu)入(ru)電(dian)(dian)流的(de)(de)(de)(de)正弦度。引入(ru)了(le)輸(shu)入(ru)電(dian)(dian)壓(ya)(ya)前饋(kui),克服輸(shu)入(ru)電(dian)(dian)壓(ya)(ya)擾動對(dui)輸(shu)出(chu)電(dian)(dian)壓(ya)(ya)的(de)(de)(de)(de)影響(xiang)。

圖7 具(ju)有輸入電(dian)壓前(qian)饋的平均(jun)電(dian)流控制 Boost 變換(huan)器的PFC

六、校正方式

對控制(zhi)(zhi)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)的(de)(de)要求,通(tong)常以(yi)性能指標的(de)(de)形(xing)式給(gei)出。而為了(le)使系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)獲得滿意的(de)(de)性能,必須對控制(zhi)(zhi)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)進行(xing)設計和校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng),也(ye)就是(shi)在(zai)(zai)(zai)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)中(zhong)適(shi)當(dang)的(de)(de)位置(zhi)(zhi)(zhi)加進適(shi)當(dang)的(de)(de)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)。校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)彌補了(le)原系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)的(de)(de)性能缺陷。按照校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)在(zai)(zai)(zai)開關電(dian)源系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)中(zhong)的(de)(de)連接(jie)方(fang)式,控制(zhi)(zhi)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)的(de)(de)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)方(fang)式可(ke)以(yi)分為串(chuan)聯校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)、反(fan)(fan)饋(kui)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)、前(qian)饋(kui)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)、復合校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)等。如(ru)圖(tu)8所(suo)示為系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)位置(zhi)(zhi)(zhi)示意圖(tu),G(S)為被控對象(主功率電(dian)路);串(chuan)聯校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)一(yi)般連接(jie)在(zai)(zai)(zai)G(S)之(zhi)前(qian),串(chuan)接(jie)與(yu)(yu)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)前(qian)向通(tong)道(dao)之(zhi)中(zhong),如(ru)G1(S)益所(suo)示;反(fan)(fan)饋(kui)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)連接(jie)在(zai)(zai)(zai)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)局(ju)部反(fan)(fan)饋(kui)通(tong)路之(zhi)中(zhong),如(ru)G2(S)位置(zhi)(zhi)(zhi)所(suo)示;補償給(gei)定量(liang)的(de)(de)前(qian)饋(kui)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)接(jie)在(zai)(zai)(zai)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)給(gei)定量(liang)之(zhi)后(hou)的(de)(de)前(qian)向通(tong)道(dao)之(zhi)上,形(xing)成前(qian)饋(kui)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)通(tong)路,如(ru)G3(S)位置(zhi)(zhi)(zhi)所(suo)示,補償擾動量(liang)的(de)(de)前(qian)饋(kui)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)接(jie)在(zai)(zai)(zai)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)可(ke)測試的(de)(de)振動量(liang)之(zhi)后(hou),形(xing)成一(yi)條附加的(de)(de)通(tong)道(dao),如(ru)G4(S)位置(zhi)(zhi)(zhi)所(suo)示。前(qian)饋(kui)校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)裝(zhuang)置(zhi)(zhi)(zhi)可(ke)以(yi)單獨作用與(yu)(yu)開環控制(zhi)(zhi)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong),也(ye)可(ke)以(yi)作為反(fan)(fan)饋(kui)控制(zhi)(zhi)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)的(de)(de)附加校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)而組成復合校(xiao)(xiao)(xiao)(xiao)(xiao)正(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)(zheng)控制(zhi)(zhi)系(xi)(xi)(xi)(xi)(xi)(xi)統(tong)(tong)(tong)(tong)。

圖8 系統校(xiao)正裝置(zhi)(zhi)位置(zhi)(zhi)示(shi)意圖

七、小結

開(kai)關電源(yuan)系(xi)統通過控(kong)(kong)制電路(lu)對主功率(lv)電路(lu)的(de)控(kong)(kong)制實現(xian)電能(neng)的(de)變換。開(kai)關電源(yuan)系(xi)統有多種控(kong)(kong)制方(fang)(fang)式(shi),而控(kong)(kong)制方(fang)(fang)式(shi)的(de)核心(xin)是(shi)校正方(fang)(fang)式(shi)。究(jiu)竟選用哪種控(kong)(kong)制方(fang)(fang)式(shi),系(xi)統如何校正,取決(jue)于系(xi)統主功率(lv)電路(lu)的(de)被控(kong)(kong)量的(de)性質(zhi)、抗(kang)擾動(dong)性要求(qiu)、技術(shu)實現(xian)的(de)方(fang)(fang)便性、經濟性要求(qiu)、環境使用條件等因素。