電源路徑管理提升開關充電器效率

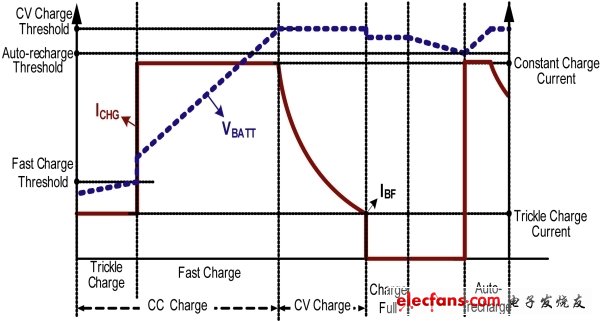

鋰離子(Li-ion)電(dian)(dian)(dian)池(chi)和鋰聚合物(wu)(Li-po)電(dian)(dian)(dian)池(chi)最(zui)(zui)適合當前市場對功率密度(du)、充(chong)電(dian)(dian)(dian)能(neng)力和價格的要求。但是,有別于鉛酸(suan)、鎳氫等其他流行的電(dian)(dian)(dian)池(chi)技(ji)術,鋰電(dian)(dian)(dian)池(chi)技(ji)術的性能(neng)也最(zui)(zui)不穩定:鋰電(dian)(dian)(dian)池(chi)充(chong)放電(dian)(dian)(dian)若管(guan)理不善(shan),將導致充(chong)電(dian)(dian)(dian)時(shi)間長(chang)、耗散功率高、效(xiao)率低和電(dian)(dian)(dian)池(chi)壽命比平(ping)均壽命低等問題。圖1顯示了典(dian)型鋰離子電(dian)(dian)(dian)池(chi)的充(chong)電(dian)(dian)(dian)曲線。

傳統充電器相對(dui)簡(jian)單,這些充電(dian)器(qi)(qi)在小(xiao)功率(lv)應用中(zhong)(zhong)表現(xian)較(jiao)好。然而,它們卻不(bu)能有效(xiao)地適應充電(dian)曲線的變化,比如,用戶(hu)在不(bu)同電(dian)源之間切換或者在充電(dian)期間操作設(she)備。另外,傳統充電(dian)器(qi)(qi)在大功率(lv)和(he)大電(dian)流應用中(zhong)(zhong),通(tong)常效(xiao)率(lv)較(jiao)低,耗散功率(lv)較(jiao)大。

圖1:典型鋰離子電池的充電曲線。

新型線性和開關充電器,比如(ru)芯源(yuan)系統(MPS)公司(si)的MP2600系列,采用電源(yuan)路徑管理技術改變(bian)了充電曲線(xian),從而能夠以(yi)更(geng)低的耗散功率更(geng)加高效地為(wei)電池/系統供(gong)電。同時(shi),這些充電器也使系統的安全性和(he)電池的使用壽命得到提高。

電(dian)(dian)源管理拓撲種(zhong)類繁(fan)多(duo),本文則重點(dian)介紹以下三種(zhong):電(dian)(dian)池饋(kui)電(dian)(dian)、自(zi)動選擇和動態電(dian)(dian)源路徑。

電池饋電拓撲

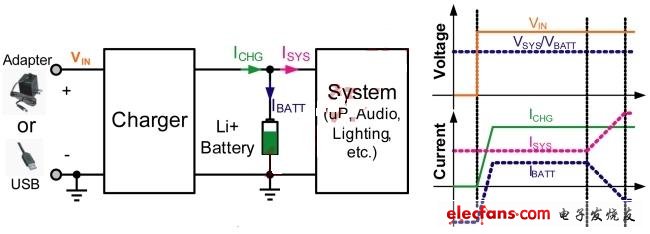

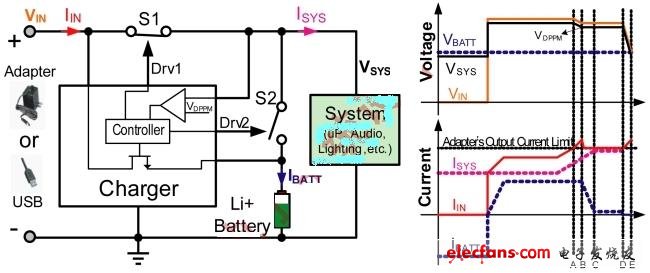

電(dian)池(chi)饋電(dian)拓撲是(shi)一種實現(xian)過(guo)程最簡(jian)單、成本最低的拓撲,這是(shi)因為其電(dian)路由充電(dian)器、電(dian)池(chi)和系統組(zu)成,如(ru)圖2所示(shi)。

圖2:電池饋電拓撲原(yuan)理(li)圖及(ji)信號圖。

這種拓撲有三個主要特性(xing):無論供電(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)如何(he)變化,系(xi)統(tong)電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)始終等(deng)于電(dian)(dian)(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya),電(dian)(dian)(dian)(dian)(dian)(dian)源系(xi)統(tong)始終優(you)先,以便IBATT £ ICHG,并且ICHG最終限制由輸入電(dian)(dian)(dian)(dian)(dian)(dian)源提(ti)供給系(xi)統(tong)電(dian)(dian)(dian)(dian)(dian)(dian)源總線(xian)的(de)最大功率(lv)。當(dang)系(xi)統(tong)與充電(dian)(dian)(dian)(dian)(dian)(dian)器斷開(kai)時該拓撲還可(ke)以實現最小(xiao)的(de)耗散功率(lv),設(she)置(zhi)ICHG從根本上(shang)限定了總輸入電(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu),這樣,隨著系(xi)統(tong)電(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(ISYS)的(de)增加,充電(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(IBATT)將等(deng)額下降,工(gong)作波形(xing)如圖2所示。

遺憾的是,這(zhe)種拓(tuo)撲有(you)如下不(bu)足之(zhi)處(chu),從而限制了它在更廣應用領(ling)域的效(xiao)率和效(xiao)用:

在電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓太低(di)(di)(di)(di)的(de)情況下(xia)(xia),系(xi)統無(wu)法工(gong)作。電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓跌至(zhi)涓流充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)門限(xian)以(yi)下(xia)(xia)時(shi),充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)器(qi)將(jiang)把總的(de)輸出電(dian)(dian)(dian)(dian)(dian)(dian)(dian)流限(xian)制得(de)很(hen)低(di)(di)(di)(di)。系(xi)統的(de)額外電(dian)(dian)(dian)(dian)(dian)(dian)(dian)源需(xu)求將(jiang)由電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)來補充,從而導致(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)能量進一步耗盡。由于系(xi)統電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓始終等于電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓,一旦電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓低(di)(di)(di)(di)到系(xi)統最低(di)(di)(di)(di)工(gong)作電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓以(yi)下(xia)(xia),系(xi)統將(jiang)停止工(gong)作。

雖然電(dian)(dian)(dian)池(chi)已具有滿電(dian)(dian)(dian)量,但是充電(dian)(dian)(dian)器無法(fa)進(jin)入(ru)EOC(結束充電(dian)(dian)(dian))狀(zhuang)態。如(ru)果ISYS超過電(dian)(dian)(dian)池(chi)滿電(dian)(dian)(dian)量門限(IBF),那么(me)ICHG就無法(fa)降到(dao)低(di)于IBF,充電(dian)(dian)(dian)狀(zhuang)態始終顯示正在充電(dian)(dian)(dian),即使電(dian)(dian)(dian)池(chi)已經具有滿電(dian)(dian)(dian)量。

電(dian)(dian)池無法充(chong)滿。由于系統優先于電(dian)(dian)池供(gong)電(dian)(dian),因此(ci)(ci)電(dian)(dian)池只能以低電(dian)(dian)流(liu)進行(xing)充(chong)電(dian)(dian)。此(ci)(ci)外,充(chong)電(dian)(dian)器只能在預期的有效(xiao)充(chong)電(dian)(dian)時間(jian)內工作,這樣(yang)可以避(bi)免給壞電(dian)(dian)池充(chong)電(dian)(dian)。如充(chong)電(dian)(dian)時間(jian)超出此(ci)(ci)時間(jian)段(duan),會導致充(chong)電(dian)(dian)器誤判(pan)壞電(dian)(dian)池而停(ting)止充(chong)電(dian)(dian)。

電源路徑自(zi)動(dong)選擇拓撲

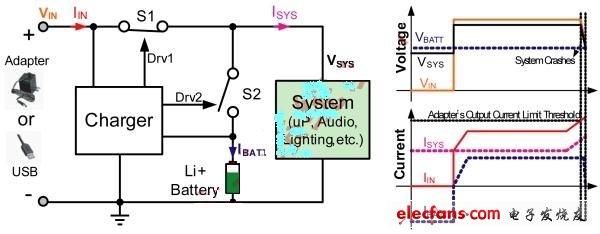

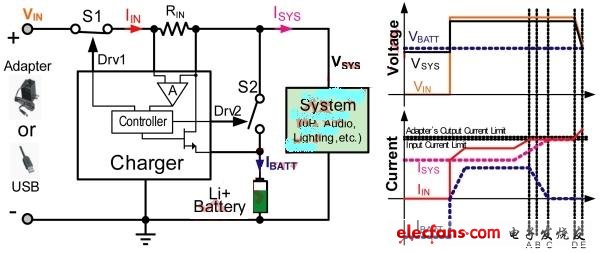

電源路(lu)徑自(zi)動選(xuan)擇拓(tuo)(tuo)撲(pu)在(zai)電池(chi)直(zhi)接搭(da)載拓(tuo)(tuo)撲(pu)基礎上外加了兩個開(kai)關(guan)管,使得(de)系統(tong)電源可以根據輸入(ru)電壓的變化在(zai)適配器和電池(chi)之間來回切換。拓(tuo)(tuo)撲(pu)結構及工作波形如圖(tu)3所(suo)示。

圖3:電源路徑自動選擇拓(tuo)撲(pu)及工(gong)作(zuo)波(bo)形(xing)。

與電池饋電拓撲結構相比,此拓撲有實質性的改進。它將系統直接跟交流適配器相連,與充電器獨立開來,因而能夠提供更大的系統電流、更高的效率并且允許系統在低電池電壓下工作。此外,其價格也比較低廉。然而,當適配器輸出電壓變化較大的時候,系統電壓也會隨之變化,所以此拓撲要求系統能夠接受比較寬的輸入電壓變化范圍。此外,也要求適配器具有更高的額定功率,以滿足系統和充電器的(de)最(zui)大總(zong)功(gong)率需求(qiu),以及系統負載突變時(shi)的(de)功(gong)率變化要求(qiu)。

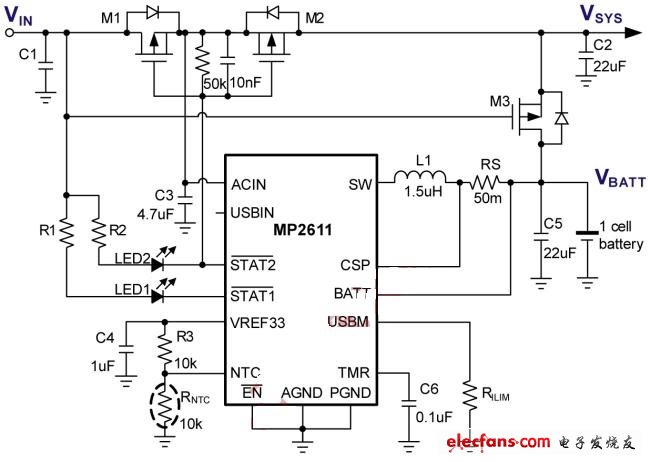

圖(tu)4是采用MPS公司的(de)(de)MP2611構成的(de)(de)電(dian)源路徑(jing)自動選擇拓撲(pu)的(de)(de)原理(li)圖(tu)。為了防(fang)止出(chu)現不穩定情況,當VBATT接(jie)近VIN時,MP2611會斷開系(xi)統(tong)與電(dian)池(chi)的(de)(de)連(lian)接(jie)。此外(wai),它(ta)還(huan)會在S1 (M1及M2)與S2(M3)之間插(cha)入(ru)一(yi)個消隱期,以防(fang)出(chu)現電(dian)流貫通,從而損壞系(xi)統(tong)和電(dian)池(chi)。

圖(tu)4:采用MP2611構成的電源路徑(jing)自動選擇拓撲。

動態電源(yuan)路徑管理拓撲(DPPM)

動態(tai)電(dian)(dian)源路徑管理(DPPM)技術(shu)采(cai)用了一套附加(jia)的檢測(ce)模(mo)塊,測(ce)量(liang)系統(tong)電(dian)(dian)壓或者輸入電(dian)(dian)流(liu),實時監(jian)測(ce)總功(gong)(gong)率需求。一旦功(gong)(gong)率需求超過(guo)預設值,通過(guo)充電(dian)(dian)器降低充電(dian)(dian)電(dian)(dian)流(liu)來保證適配(pei)器輸出功(gong)(gong)率恒定而不過(guo)載。

例如,基(ji)于(yu)(yu)輸(shu)入(ru)(ru)電(dian)(dian)(dian)壓(ya)(ya)的DPPM(圖(tu)5)通過比較輸(shu)入(ru)(ru)電(dian)(dian)(dian)壓(ya)(ya)與預(yu)設(she)參考電(dian)(dian)(dian)壓(ya)(ya)來判(pan)斷輸(shu)入(ru)(ru)電(dian)(dian)(dian)流(liu)是(shi)否達(da)(da)到適配器(qi)的輸(shu)出電(dian)(dian)(dian)流(liu)限制(zhi)。若適配器(qi)電(dian)(dian)(dian)流(liu)已經達(da)(da)到該限制(zhi),適配器(qi)電(dian)(dian)(dian)壓(ya)(ya)將降至預(yu)設(she)參考電(dian)(dian)(dian)壓(ya)(ya),然后充(chong)(chong)電(dian)(dian)(dian)器(qi)通過動態降低充(chong)(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流(liu)來防止系統電(dian)(dian)(dian)壓(ya)(ya)繼續(xu)下降。只(zhi)要輸(shu)入(ru)(ru)電(dian)(dian)(dian)流(liu)保持在該限制(zhi)的水平或(huo)(huo)者低于(yu)(yu)該限制(zhi),就(jiu)仍然有電(dian)(dian)(dian)流(liu)向電(dian)(dian)(dian)池充(chong)(chong)電(dian)(dian)(dian)。然而,由系統電(dian)(dian)(dian)壓(ya)(ya)下降引(yin)起的不穩定(ding)或(huo)(huo)噪(zao)聲(sheng)使得這種(zhong)基(ji)于(yu)(yu)電(dian)(dian)(dian)壓(ya)(ya)的DPPM結構(gou)不適合(he)應用(yong)在某些對噪(zao)聲(sheng)敏感的場合(he),比如音頻設(she)備。

圖5:基于輸(shu)入電壓的動態電源路(lu)徑管理。

基于輸入(ru)電(dian)流(liu)的DPPM(圖6)采用檢測電(dian)阻來評估(gu)輸入(ru)電(dian)流(liu),當輸入(ru)電(dian)流(liu)達到預設電(dian)流(liu)門(men)限(xian)時,通過動態(tai)降(jiang)低(di)(di)電(dian)池電(dian)流(liu)來防止適(shi)(shi)配(pei)器過載或(huo)系(xi)統電(dian)壓(ya)下降(jiang)。這樣就保證了系(xi)統電(dian)壓(ya)的穩定(ding),降(jiang)低(di)(di)了適(shi)(shi)配(pei)器的額外功率要求。同時,該拓撲還(huan)具(ju)備(bei)電(dian)池反向補充供電(dian)的能力。

圖6:基于輸入電流的動態電源(yuan)路徑(jing)管理。

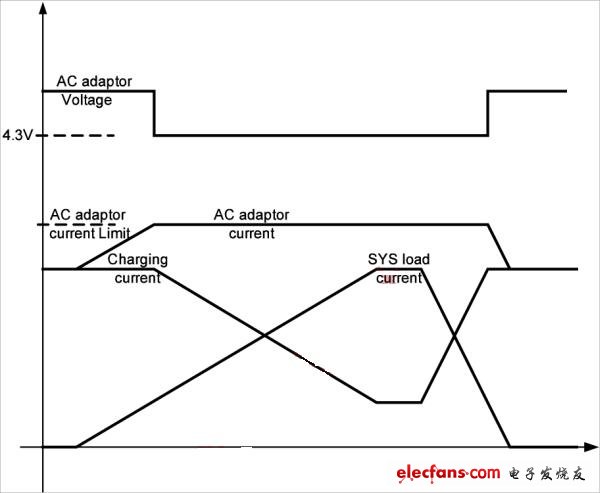

有些充電器(例如MPS公司的MP2607)可以根據不同電源要求,優化選擇不同的動態電源路徑管理方案。MP2607根據不同的適配器類型,在基于輸入電壓和基于輸入電流的DPPM兩種拓撲之間進行智能選擇。若輸入是交流適配器,MP2607采用基于輸入電壓的DPPM技術,控制適配器交流電壓,使得交流適配器可以同時為系統供電和為電池充電,工作波形如(ru)圖7所(suo)示。

圖7:MP2607在(zai)交(jiao)流適配器輸入時(shi)的動(dong)態電(dian)源路徑(jing)管理(li)。

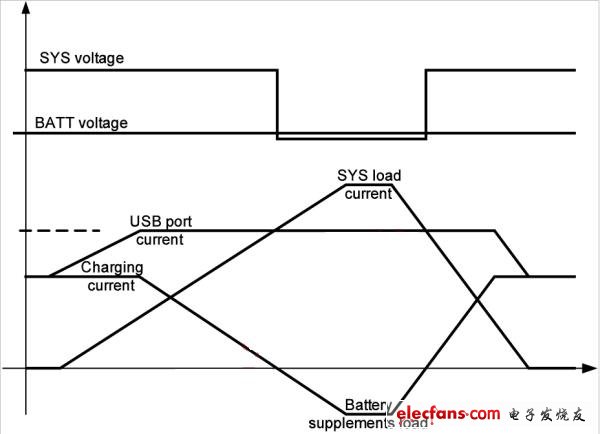

在USB輸入模式下,MP2607采用基于輸入電(dian)(dian)(dian)流的DPPM.如圖8所示,考(kao)慮到USB提供(gong)電(dian)(dian)(dian)流能力有限,設置充(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流在USB限制(zhi)電(dian)(dian)(dian)流以下。若系統負載電(dian)(dian)(dian)流大于USB限流值,電(dian)(dian)(dian)池將(jiang)反(fan)向補充(chong)供(gong)電(dian)(dian)(dian)。

圖8:MP2607在(zai)USB輸入時的動(dong)態(tai)電源路徑管理(li)。

總之,具有動態電源路徑管理的充電器(尤其是那(nei)些能在不同(tong)管理模式之間切換(huan)的(de)充電(dian)器)可以(yi)為移動電(dian)子設備提供更加精妙的(de)電(dian)源解決方案(an),從(cong)而(er)給用戶帶來(lai)前所(suo)未有的(de)便(bian)利、性能和效率。