單體鋰離子電池應用充電器IC

單體鋰離子 (Li-Ion) 電池充電器的選項有很多種。隨著手持設備業務的不斷發展,對電池充電器的要求也不斷增加。要為完成這項工作而選擇正確的集成電路 (IC),我們必須權衡幾個因素。在開始設計以前,我們必須考慮諸如解決方案尺寸、USB標準、充電速率和成本等因素。必須將這些因素按照重要程度依次排列,然后選擇相應的充電器IC。本文中,我們將介紹不同的充電拓撲結構,并研究電池充電器IC的(de)一(yi)些特(te)性。此外,我們還將探討一(yi)個應用和現有的(de)解決(jue)方(fang)案。

鋰離子電池充電周期

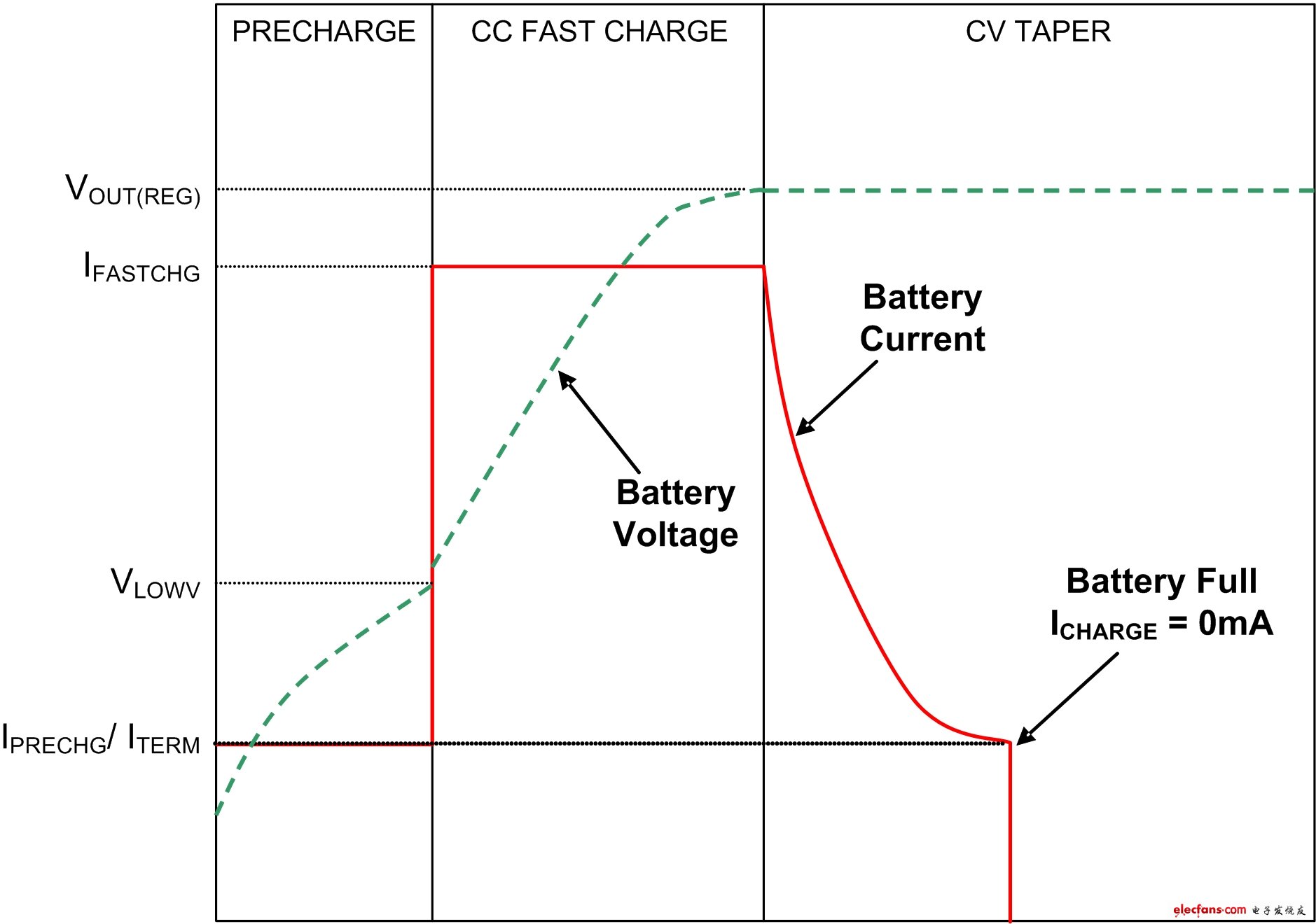

鋰離子電池要求專門的充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)周(zhou)期(qi),以(yi)(yi)(yi)實現安(an)全(quan)充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)并最大化(hua)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)使用時(shi)(shi)間。電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)分兩個階(jie)段:恒定(ding)(ding)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu) (CC) 和恒定(ding)(ding)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓 (CV)。電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)位于完全(quan)充(chong)(chong)(chong)滿電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓以(yi)(yi)(yi)下(xia)時(shi)(shi),電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)經(jing)過穩(wen)壓進入電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)。在(zai)CC模式下(xia),電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)經(jing)過穩(wen)壓達到兩個值之(zhi)一(yi)。如(ru)果電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓非(fei)常(chang)低(di),則(ze)充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)降低(di)至(zhi)預充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)平,以(yi)(yi)(yi)適應電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)并防(fang)止(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)損壞。該(gai)閾值因電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)化(hua)學屬性而不同,一(yi)般(ban)取決于電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)制(zhi)造廠(chang)商(shang)。一(yi)旦(dan)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓升至(zhi)預充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)閾值以(yi)(yi)(yi)上(shang),充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)便升至(zhi)快速充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)平。典型(xing)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)的最大建(jian)議快速充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)為1C(C=1 小(xiao)時(shi)(shi)內耗盡電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)所(suo)需的電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)),但(dan)該(gai)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)也取決地電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)制(zhi)造廠(chang)商(shang)。典型(xing)充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)為~0.8C,目(mu)的是最大化(hua)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)使用時(shi)(shi)間。對(dui)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)時(shi)(shi),電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓上(shang)升。一(yi)旦(dan)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓升至(zhi)穩(wen)壓電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(一(yi)般(ban)為4.2V),充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)逐(zhu)漸(jian)減少(shao),同時(shi)(shi)對(dui)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓進行穩(wen)壓以(yi)(yi)(yi)防(fang)止(zhi)過充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)。在(zai)這種模式下(xia),電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)時(shi)(shi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)逐(zhu)漸(jian)減少(shao),同時(shi)(shi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)阻抗(kang)降低(di)。如(ru)果電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)降至(zhi)預定(ding)(ding)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)平(一(yi)般(ban)為快速充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)(liu)的10%),則(ze)終止(zhi)充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)。我們一(yi)般(ban)不對(dui)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)浮(fu)充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian),因為這樣會縮(suo)短電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)(chi)(chi)(chi)(chi)使用壽(shou)命。圖(tu)1 以(yi)(yi)(yi)圖(tu)形方式說明(ming)了典型(xing)的充(chong)(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)周(zhou)期(qi)。

圖1典型鋰離子充電周期

線性解(jie)決方(fang)案與(yu)開(kai)關(guan)模(mo)式解(jie)決方(fang)案對比

將(jiang)適(shi)配器(qi)電(dian)壓轉降為(wei)電(dian)池電(dian)壓并控制(zhi)不同充電(dian)階段的拓(tuo)(tuo)撲結(jie)構(gou)有兩種(zhong):線性(xing)穩(wen)壓器(qi)和電(dian)感開關。這兩種(zhong)拓(tuo)(tuo)撲結(jie)構(gou)在體(ti)積、效率、解決(jue)方案成本(ben)和電(dian)磁干擾 (EMI) 輻射方面(mian)各(ge)有優缺點。我們下(xia)面(mian)介紹這兩種(zhong)拓(tuo)(tuo)撲結(jie)構(gou)的各(ge)種(zhong)優點和一些(xie)折中方法。

一(yi)般來(lai)說,電(dian)(dian)(dian)(dian)(dian)感開(kai)(kai)關(guan)是獲得最(zui)高(gao)效率(lv)的(de)(de)(de)最(zui)佳選擇(ze)。利用電(dian)(dian)(dian)(dian)(dian)阻器(qi)等檢(jian)(jian)測組件(jian)(jian)(jian),在輸(shu)(shu)出(chu)端(duan)檢(jian)(jian)測充(chong)電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)流。充(chong)電(dian)(dian)(dian)(dian)(dian)器(qi)在CC 模式(shi)(shi)下時,電(dian)(dian)(dian)(dian)(dian)流反(fan)饋電(dian)(dian)(dian)(dian)(dian)路(lu)控(kong)制占空比(bi)。電(dian)(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)(dian)壓檢(jian)(jian)測反(fan)饋電(dian)(dian)(dian)(dian)(dian)路(lu)控(kong)制CV 模式(shi)(shi)下的(de)(de)(de)占空比(bi)。根據特性集的(de)(de)(de)不(bu)(bu)同(tong),可能會(hui)出(chu)現其(qi)他(ta)一(yi)些(xie)控(kong)制環路(lu)。我們將在后(hou)面詳細討(tao)論(lun)這(zhe)些(xie)環路(lu)。電(dian)(dian)(dian)(dian)(dian)感開(kai)(kai)關(guan)電(dian)(dian)(dian)(dian)(dian)路(lu)要(yao)(yao)求開(kai)(kai)關(guan)組件(jian)(jian)(jian)、整(zheng)流器(qi)、電(dian)(dian)(dian)(dian)(dian)感和輸(shu)(shu)入及(ji)輸(shu)(shu)出(chu)電(dian)(dian)(dian)(dian)(dian)容器(qi)。就(jiu)許多應用而言,通過(guo)選擇(ze)一(yi)種(zhong)將開(kai)(kai)關(guan)組件(jian)(jian)(jian)和整(zheng)流器(qi)都嵌入到(dao)IC 中的(de)(de)(de)器(qi)件(jian)(jian)(jian),可以縮小解決方案的(de)(de)(de)尺寸(cun)。根據不(bu)(bu)同(tong)的(de)(de)(de)負載,這(zhe)些(xie)電(dian)(dian)(dian)(dian)(dian)路(lu)的(de)(de)(de)典型效率(lv)為80% 到(dao)96%。開(kai)(kai)關(guan)轉(zhuan)換器(qi)因(yin)其(qi)電(dian)(dian)(dian)(dian)(dian)感尺寸(cun)一(yi)般會(hui)要(yao)(yao)求更多的(de)(de)(de)空間,同(tong)時也更加昂(ang)貴。開(kai)(kai)關(guan)轉(zhuan)換器(qi)還會(hui)引(yin)起(qi)電(dian)(dian)(dian)(dian)(dian)感EMI 輻射,以及(ji)開(kai)(kai)關(guan)帶來(lai)的(de)(de)(de)輸(shu)(shu)出(chu)端(duan)噪(zao)聲(sheng)。

線性充電器通過(guo)降(jiang)低(di)旁路(lu)(lu)組(zu)件的(de)(de)輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)電(dian)(dian)(dian)壓(ya),降(jiang)低(di)DC 電(dian)(dian)(dian)壓(ya)。這樣(yang)做(zuo)的(de)(de)好處(chu)是解(jie)決(jue)方(fang)案(an)只要求(qiu)三個組(zu)件:旁路(lu)(lu)組(zu)件和輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)/輸(shu)(shu)(shu)(shu)出(chu)電(dian)(dian)(dian)容。相比電(dian)(dian)(dian)感開(kai)關,線(xian)性壓(ya)降(jiang)穩(wen)壓(ya)器(qi)(qi) (LDO) 通常為一款低(di)成本的(de)(de)解(jie)決(jue)方(fang)案(an),且噪聲更低(di)。通過(guo)穩(wen)壓(ya)旁路(lu)(lu)組(zu)件的(de)(de)電(dian)(dian)(dian)阻來(lai)限制(zhi)進(jin)入(ru)(ru)(ru)電(dian)(dian)(dian)池(chi)(chi)的(de)(de)電(dian)(dian)(dian)流(liu)(liu),從(cong)而(er)對充(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流(liu)(liu)進(jin)行(xing)控制(zhi)。電(dian)(dian)(dian)流(liu)(liu)反饋(kui)一般來(lai)自充(chong)電(dian)(dian)(dian)器(qi)(qi)IC 的(de)(de)輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)。對電(dian)(dian)(dian)池(chi)(chi)電(dian)(dian)(dian)壓(ya)進(jin)行(xing)檢測,以提供CV 反饋(kui)。改變旁路(lu)(lu)組(zu)件的(de)(de)電(dian)(dian)(dian)阻,來(lai)維(wei)持(chi)進(jin)入(ru)(ru)(ru)IC 輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)端的(de)(de)恒(heng)定(ding)電(dian)(dian)(dian)流(liu)(liu)或者恒(heng)定(ding)電(dian)(dian)(dian)池(chi)(chi)電(dian)(dian)(dian)壓(ya)。器(qi)(qi)件的(de)(de)輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)電(dian)(dian)(dian)流(liu)(liu)等(deng)于負載電(dian)(dian)(dian)流(liu)(liu)。這就是說解(jie)決(jue)方(fang)案(an)的(de)(de)效(xiao)率等(deng)于輸(shu)(shu)(shu)(shu)出(chu)電(dian)(dian)(dian)壓(ya)與輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)電(dian)(dian)(dian)壓(ya)的(de)(de)比。LDO 解(jie)決(jue)方(fang)案(an)的(de)(de)缺點是高(gao)輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)輸(shu)(shu)(shu)(shu)出(chu)電(dian)(dian)(dian)壓(ya)比時(即低(di)電(dian)(dian)(dian)量情況)效(xiao)率較低(di)。所(suo)有功率都被旁路(lu)(lu)組(zu)件消耗(hao),其意味著LDO 并非(fei)那些輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)輸(shu)(shu)(shu)(shu)出(chu)差(cha)較大的(de)(de)高(gao)充(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流(liu)(liu)應用的(de)(de)理想(xiang)選(xuan)擇。這些高(gao)功耗(hao)應用要求(qiu)散熱,從(cong)而(er)增(zeng)加了解(jie)決(jue)方(fang)案(an)的(de)(de)尺(chi)寸。

功耗及溫升計算

其中,η為充電器的效率,而POUT = VOUT × IOUT。利用熱阻,可以計算得到功耗帶來的溫升。每種應用的熱阻都不同,其取決于電路板布局、氣流和封裝等具體參數。我們應該針對終端應用電路板對熱阻建模。請記住,產品說明書中定義的ΘJA 并非這種應用中熱阻的恰當表示方法。

應該使用什么樣的(de)拓撲(pu)?

您需要研究的第一個參數是充電電流。對于一些小型應用來說,例如:充電電流介于25Ma 到150mA 之間的藍牙TM耳機等,最佳解決方案幾乎都是線性充電器。這些應用一般都具有非常小的體積,無法為開關的更多組件提供額外空間。另外,由于其非常低的功耗要求,功耗帶來的溫升可以忽略不計。對于手機應用來說,充電電流一般在350-700mA 范圍以內。在這種范圍中,很多時候線性解決方案仍然非常有效。由于它們通常都為低成本手機,其成本壓力更大,因此線性充電器便成為一種理想的解決方案。智能手機應用的電池體積較大,且充電電流需求大于1.5A,這時使用開關解決方案則更加合理。1.5A 電流條件下,溫升會非常大。例如,使用一個線性充電器通過5V 適配器對一塊3.6V 電池充電時(shi),效(xiao)率(lv)為(wei)72%。首先,這個效(xiao)率(lv)聽(ting)起來似(si)乎不(bu)太壞(huai)。如果您從功(gong)(gong)耗(hao)的(de)角度來看它(ta),這種(zhong)應用(yong)要消(xiao)耗(hao)約(yue)2W。在(zai)(zai)一(yi)個熱阻(zu) (ΘJA) 為(wei)40°C/W 的(de)應用(yong)中,芯片溫(wen)度上升(sheng)(sheng)80°C。在(zai)(zai)40°C 環(huan)境溫(wen)度下,電路板溫(wen)度會上升(sheng)(sheng)至(zhi)120°C,其對手持設(she)備來說是不(bu)可接受(shou)(shou)的(de)。在(zai)(zai)極(ji)低(di)(di)(di)電池(chi)電壓(即3 V)下,這一(yi)問題甚至(zhi)會變得極(ji)端嚴重。相同3V 條件下,溫(wen)度升(sheng)(sheng)至(zhi)120°C。讓我們來看相同條件下的(de)開關解決方案,使(shi)用(yong)一(yi)個單(dan)體(ti)電池(chi)IC 充電器(qi)時(shi),效(xiao)率(lv)上升(sheng)(sheng)至(zhi)約(yue)85%。使(shi)用(yong)一(yi)塊3.6V 電池(chi)時(shi),功(gong)(gong)耗(hao)低(di)(di)(di)于1W,從而帶(dai)來40°C 的(de)溫(wen)升(sheng)(sheng)。3V 時(shi)這種(zhong)改(gai)善更(geng)加(jia)明(ming)顯。假(jia)設(she)3V 輸出時(shi)的(de)效(xiao)率(lv)為(wei)80%,則功(gong)(gong)耗(hao)低(di)(di)(di)于800 mW,因(yin)此溫(wen)升(sheng)(sheng)會更(geng)低(di)(di)(di)(約(yue)32°C)。這些智能(neng)手機的(de)體(ti)積一(yi)般可以容許稍大一(yi)點(dian)的(de)解決方案,并且能(neng)夠承受(shou)(shou)開關模式解決方案相關的(de)稍許成本增加(jia)。

為任務選擇(ze)正(zheng)確的IC

在您已經完成(cheng)您的(de)初步熱(re)分析并且選好充(chong)電(dian)(dian)(dian)器(qi)拓撲以(yi)(yi)(yi)后,您便可以(yi)(yi)(yi)轉(zhuan)到(dao)選擇應用的(de)最佳IC 上來。新型的(de)電(dian)(dian)(dian)池充(chong)電(dian)(dian)(dian)器(qi)解(jie)決(jue)方(fang)案集成(cheng)了許多特(te)性,可以(yi)(yi)(yi)利用它(ta)們改善(shan)系統的(de)性能(neng)。諸(zhu)如輸入過壓保(bao)護、電(dian)(dian)(dian)源(yuan)路(lu)徑管理 (PPM)、VIN_DPM、散熱(re)穩(wen)壓、負(fu)溫(wen)度(du)系數熱(re)敏電(dian)(dian)(dian)阻 (NTC) 監(jian)測(ce)和USB 充(chong)電(dian)(dian)(dian)等(deng)特(te)性,都被集成(cheng)到(dao)許多電(dian)(dian)(dian)池充(chong)電(dian)(dian)(dian)器(qi)IC 中(zhong)。大多數單體電(dian)(dian)(dian)池充(chong)電(dian)(dian)(dian)器(qi)解(jie)決(jue)方(fang)案都已將(jiang)要求FET 集成(cheng)到(dao)了器(qi)件(jian)中(zhong),旨在節省電(dian)(dian)(dian)路(lu)板面積。

輸(shu)(shu)入(ru)過壓保(bao)護(hu)(單(dan)輸(shu)(shu)入(ru)與雙(shuang)輸(shu)(shu)入(ru)對比)

在(zai)當今的(de)(de)(de)市(shi)(shi)場(chang)上(shang),USB 電(dian)(dian)(dian)(dian)(dian)源已經成(cheng)為(wei)(wei)最為(wei)(wei)常見的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)源,因此通過(guo)USB 電(dian)(dian)(dian)(dian)(dian)源充(chong)電(dian)(dian)(dian)(dian)(dian)已經成(cheng)為(wei)(wei)一(yi)種必然性(xing)。市(shi)(shi)場(chang)已經從使用專門AC 適(shi)配器(qi)和(he)(he)單(dan)獨USB 接(jie)(jie)口(kou)的(de)(de)(de)初始雙(shuang)輸(shu)(shu)入(ru)(ru)轉(zhuan)(zhuan)變(bian)為(wei)(wei)將一(yi)個(ge)USB 接(jie)(jie)口(kou)既(ji)作為(wei)(wei)墻上(shang)電(dian)(dian)(dian)(dian)(dian)源適(shi)合(he)器(qi)接(jie)(jie)口(kou)使用,也作為(wei)(wei)使用相同線纜的(de)(de)(de)USB 數據輸(shu)(shu)入(ru)(ru)接(jie)(jie)口(kou)的(de)(de)(de)單(dan)輸(shu)(shu)入(ru)(ru)解(jie)(jie)決(jue)方案。這(zhe)樣(yang)便(bian)導致一(yi)種從雙(shuang)輸(shu)(shu)入(ru)(ru)解(jie)(jie)決(jue)方案向單(dan)輸(shu)(shu)入(ru)(ru)解(jie)(jie)決(jue)方案的(de)(de)(de)轉(zhuan)(zhuan)移。單(dan)輸(shu)(shu)入(ru)(ru)在(zai)接(jie)(jie)口(kou)方面(mian)存在(zai)許(xu)多挑戰。由于(yu)(yu)存在(zai)如此多的(de)(de)(de)配件市(shi)(shi)場(chang)適(shi)配器(qi)解(jie)(jie)決(jue)方案和(he)(he)一(yi)種通用接(jie)(jie)口(kou),輸(shu)(shu)入(ru)(ru)端必須要能夠(gou)在(zai)無損(sun)壞(huai)的(de)(de)(de)情況下承受更高的(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)壓。由于(yu)(yu)電(dian)(dian)(dian)(dian)(dian)池充(chong)電(dian)(dian)(dian)(dian)(dian)器(qi)始終(zhong)連接(jie)(jie)到輸(shu)(shu)入(ru)(ru)端,因此充(chong)電(dian)(dian)(dian)(dian)(dian)器(qi)對所有下游電(dian)(dian)(dian)(dian)(dian)路實施過(guo)電(dian)(dian)(dian)(dian)(dian)壓狀態(tai)保護是有道理的(de)(de)(de)。為(wei)(wei)了實施這(zhe)一(yi)功能,市(shi)(shi)場(chang)上(shang)出現(xian)了許(xu)多能夠(gou)承受20V 甚(shen)至(zhi)30V 電(dian)(dian)(dian)(dian)(dian)壓的(de)(de)(de)解(jie)(jie)決(jue)方案。另外,這(zhe)些器(qi)件都(dou)具有過(guo)電(dian)(dian)(dian)(dian)(dian)壓保護 (OVP) 電(dian)(dian)(dian)(dian)(dian)路,其在(zai)輸(shu)(shu)入(ru)(ru)超出OVP 閾值時阻止器(qi)件運(yun)行。這(zhe)樣(yang)便(bian)進一(yi)步保護了下游電(dian)(dian)(dian)(dian)(dian)路,使其免(mian)受潛在(zai)的(de)(de)(de)瞬(shun)態(tai)過(guo)電(dian)(dian)(dian)(dian)(dian)壓狀態(tai)損(sun)壞(huai)。

目前,隨著綠色(se)輸(shu)入(即太陽(yang)能(neng)電(dian)(dian)池)或無線充電(dian)(dian)的出現,應(ying)用又再一次向(xiang)雙(shuang)輸(shu)入要(yao)求轉移(yi)。根據具(ju)體的應(ying)用要(yao)求,兩種(zhong)配置結構都可以使用。

電源路徑管理/最小(xiao)系統電壓

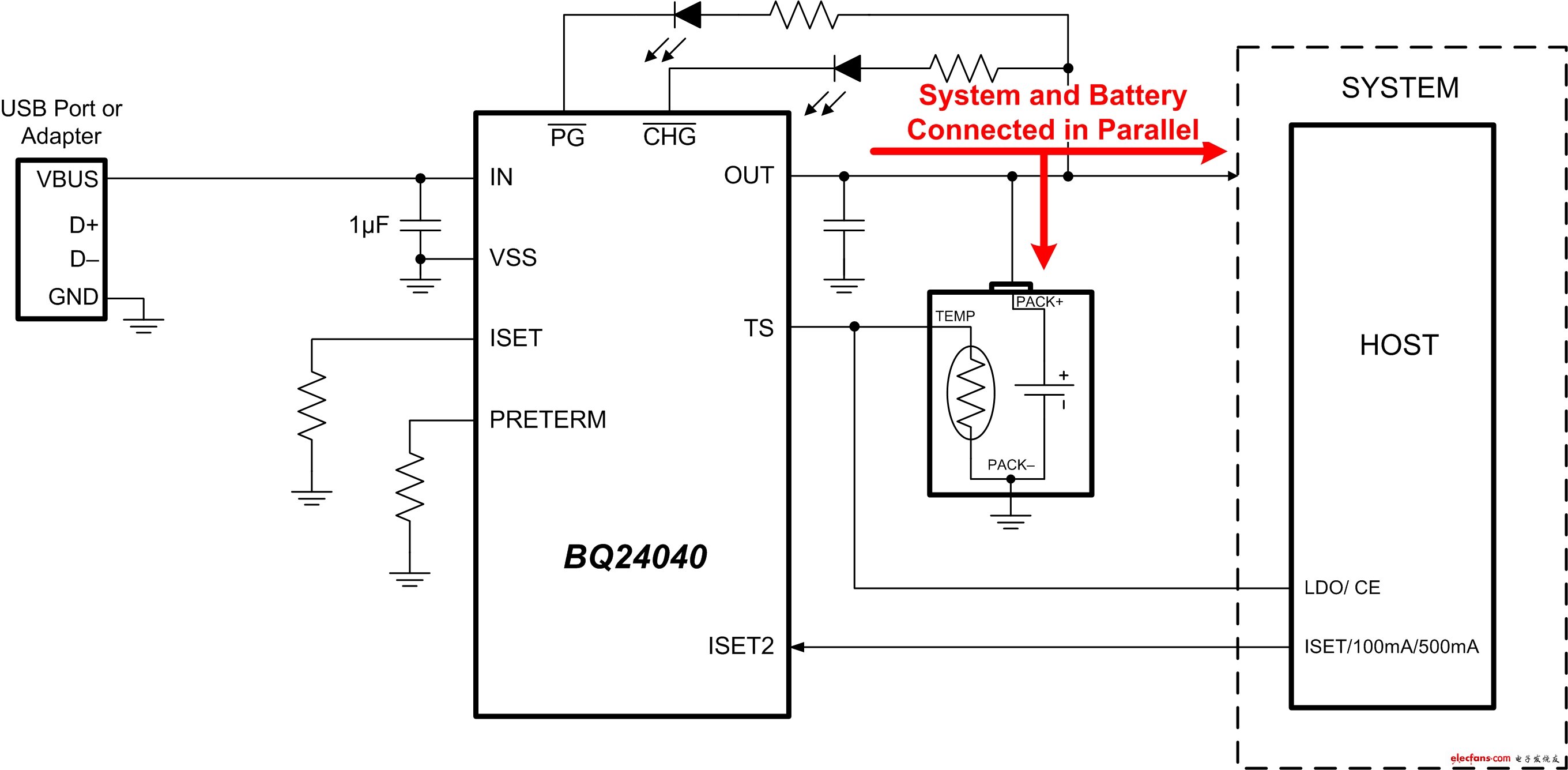

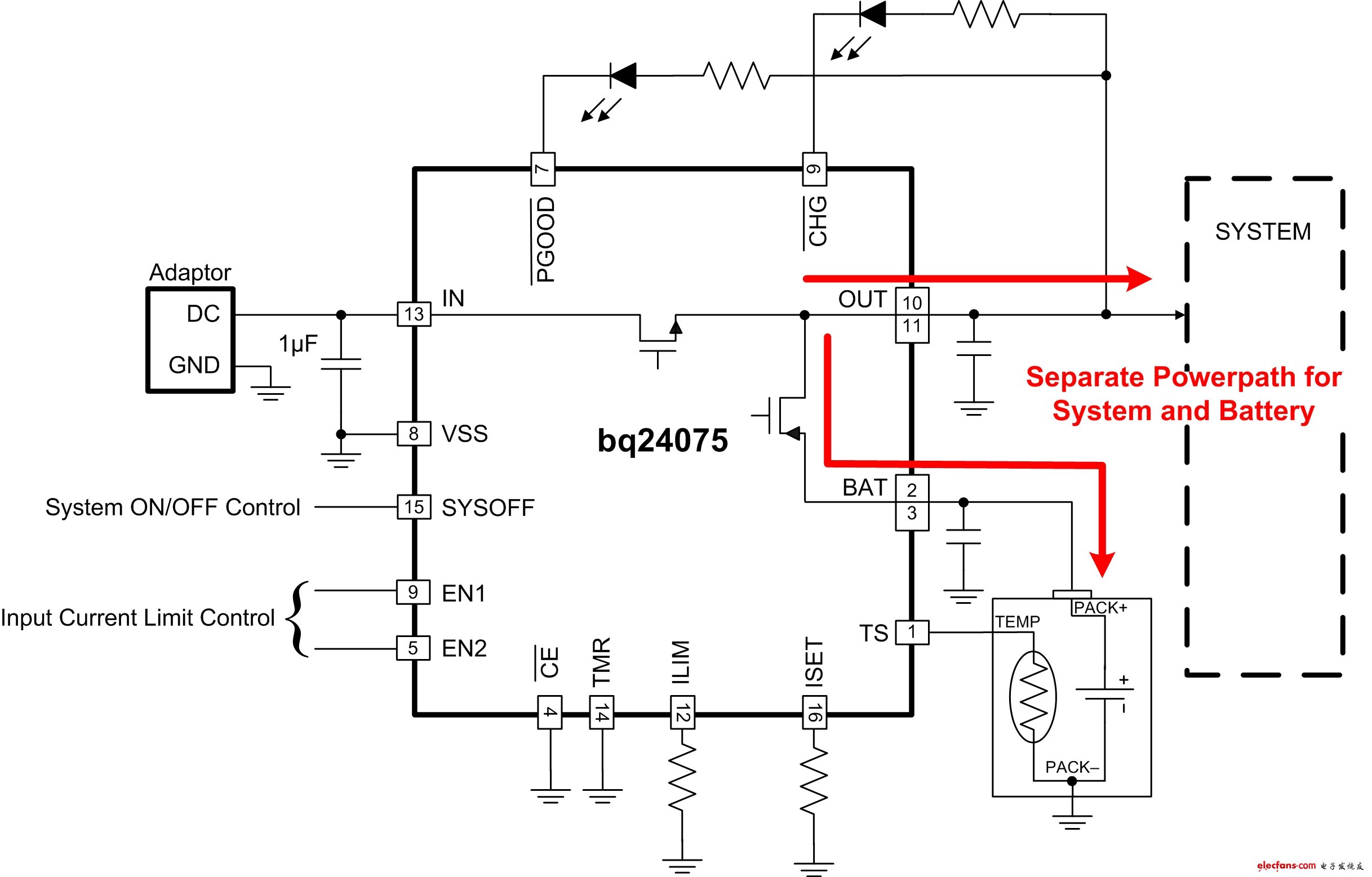

電池充電器的一般方法是將系統直接連接到電池,讓充電器同時為電池和系統供電。然后,對系統的總電流進行穩壓,這樣做存在幾個問題。特別是低電池電量啟動、終止干擾和早期計時器超時等問題。電源路徑管理通過對電池電流和(he)系統電(dian)流進(jin)行分別監測(ce),消除了這些問題(ti)[2]。

圖 2 傳統拓撲結構(gou)舉例

圖 3 電源路徑拓撲結構(gou)舉例

最低系統電壓

使用傳統方法時,系統電壓始終與電池相同。因此,電池深度放電時,在電池充電到某個可用電平以前系統都不會啟動。利用PPM,可對系統電壓單獨穩壓,將其與電池電壓區分開來。這就意味著可以實現最低系統電壓,其與電池電壓無關。對用戶而言,這就意味著連接適配器的同時他們便可以使用設備,假設條件是其具有足夠的功率來驅動系統。如bq25060 等器件就具有這種功能。

更短的充電時間

由(you)于(yu)系(xi)(xi)(xi)統(tong)(tong)電(dian)(dian)流(liu)和(he)(he)充(chong)電(dian)(dian)電(dian)(dian)流(liu)是單獨編程的(de)(de),因此可(ke)以使(shi)用適配(pei)器(qi)的(de)(de)滿功率,其與電(dian)(dian)池的(de)(de)容(rong)量(liang)和(he)(he)充(chong)電(dian)(dian)電(dian)(dian)流(liu)的(de)(de)大小均(jun)無關。傳統(tong)(tong)拓撲結構中,充(chong)電(dian)(dian)器(qi)的(de)(de)輸出(chu)電(dian)(dian)流(liu)必須(xu)設定為(wei)最大充(chong)電(dian)(dian)電(dian)(dian)流(liu),以應對沒(mei)有系(xi)(xi)(xi)統(tong)(tong)負(fu)載(zai)的(de)(de)情況。當(dang)系(xi)(xi)(xi)統(tong)(tong)中有負(fu)載(zai)時(shi),由(you)于(yu)系(xi)(xi)(xi)統(tong)(tong)吸收可(ke)用電(dian)(dian)流(liu),有效充(chong)電(dian)(dian)電(dian)(dian)流(liu)降低。例如,一(yi)(yi)個(ge)使(shi)用900 mA 適配(pei)器(qi)和(he)(he)500 mAhr 電(dian)(dian)池的(de)(de)系(xi)(xi)(xi)統(tong)(tong),使(shi)用傳統(tong)(tong)方法可(ke)以編程500 mA 的(de)(de)充(chong)電(dian)(dian)電(dian)(dian)流(liu)。如果系(xi)(xi)(xi)統(tong)(tong)負(fu)載(zai)為(wei)200 mA,有效充(chong)電(dian)(dian)電(dian)(dian)流(liu)僅(jin)為(wei)300 mA,充(chong)電(dian)(dian)時(shi)間幾乎翻了一(yi)(yi)翻。如果使(shi)用PPM 來研究這一(yi)(yi)相同案例,輸入電(dian)(dian)流(liu)限(xian)制設定為(wei)900 mA。這樣便允許(xu)全(quan)部(bu)500 mA充(chong)電(dian)(dian)電(dian)(dian)流(liu),且擁有多達(da)400 mA 的(de)(de)額外(wai)系(xi)(xi)(xi)統(tong)(tong)電(dian)(dian)流(liu)。

終止和(he)早期計時器超時

在(zai)對(dui)總電(dian)流(liu)進(jin)行(xing)穩(wen)壓的傳統(tong)(tong)(tong)系(xi)統(tong)(tong)(tong)中,電(dian)流(liu)在(zai)電(dian)池(chi)和負(fu)(fu)載之間共用(yong)。如(ru)果(guo)(guo)系(xi)統(tong)(tong)(tong)負(fu)(fu)載足夠大到從電(dian)池(chi)拉(la)取充(chong)(chong)電(dian)電(dian)流(liu),且在(zai)計時(shi)器(qi)超時(shi)以(yi)前電(dian)池(chi)不充(chong)(chong)電(dian),則計時(shi)器(qi)會出(chu)現偽超時(shi)。另外(wai),如(ru)果(guo)(guo)系(xi)統(tong)(tong)(tong)電(dian)流(liu)絕對(dui)不會降至(zhi)設定(ding)終止電(dian)流(liu)以(yi)下,則永遠不會終止。電(dian)源(yuan)路徑管理通(tong)過單獨監測充(chong)(chong)電(dian)電(dian)流(liu),并動(dong)態地使用(yong)可穩(wen)壓計時(shi)器(qi)(通(tong)過減少充(chong)(chong)電(dian)電(dian)流(liu)進(jin)行(xing)穩(wen)壓),防止這些條件出(chu)現。就終止問題(ti)而言(yan),單獨對(dui)充(chong)(chong)電(dian)電(dian)流(liu)進(jin)行(xing)監測,可讓終止條件測定(ding)變得容(rong)易。

基于輸入電壓的動(dong)態電源管理 (VIN-DPM)

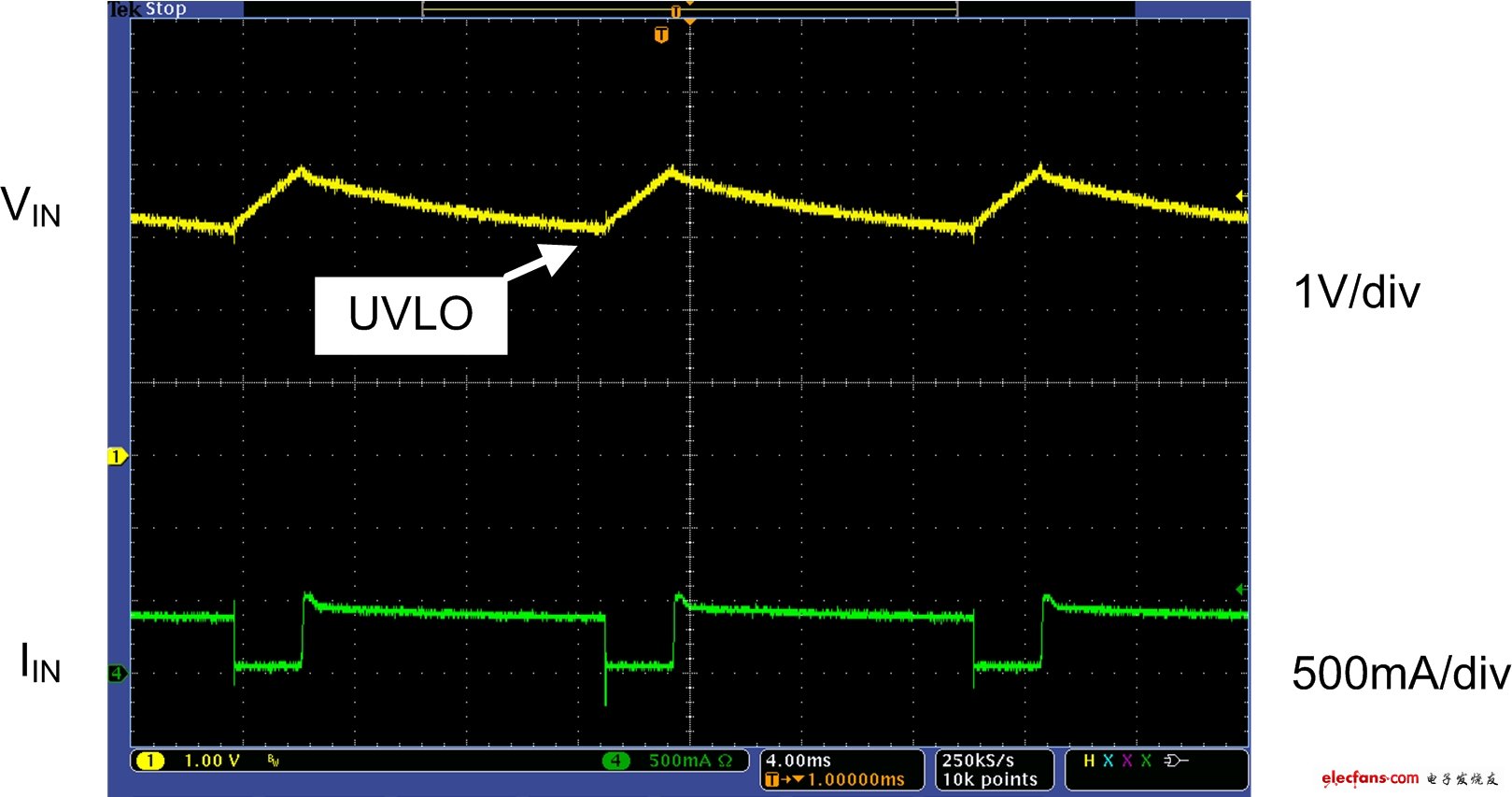

為了防止出現輸入源超負載的欠壓狀態,一些器件實施了基于輸入電壓的動態電源管理 (VIN-DPM)。這種環路降低輸入電流限制來防止輸入崩潰。VIN-DPM 環路對輸入電壓進行有效的穩壓,來最大化電源的電流。圖4 顯示了在無VIN-DPM 保護的情況下USB 端口的超負載結果。請注意,輸入電壓降至電源狀態良好閾值以下時,充電器關閉。這樣便關閉了電源負載,并允許輸入電壓恢復,從而開啟充電器。這種開/關脈沖發生并不是我們想要的。

圖(tu) 4 無(wu) VIN-DPM 情況下(xia)的輸入崩潰

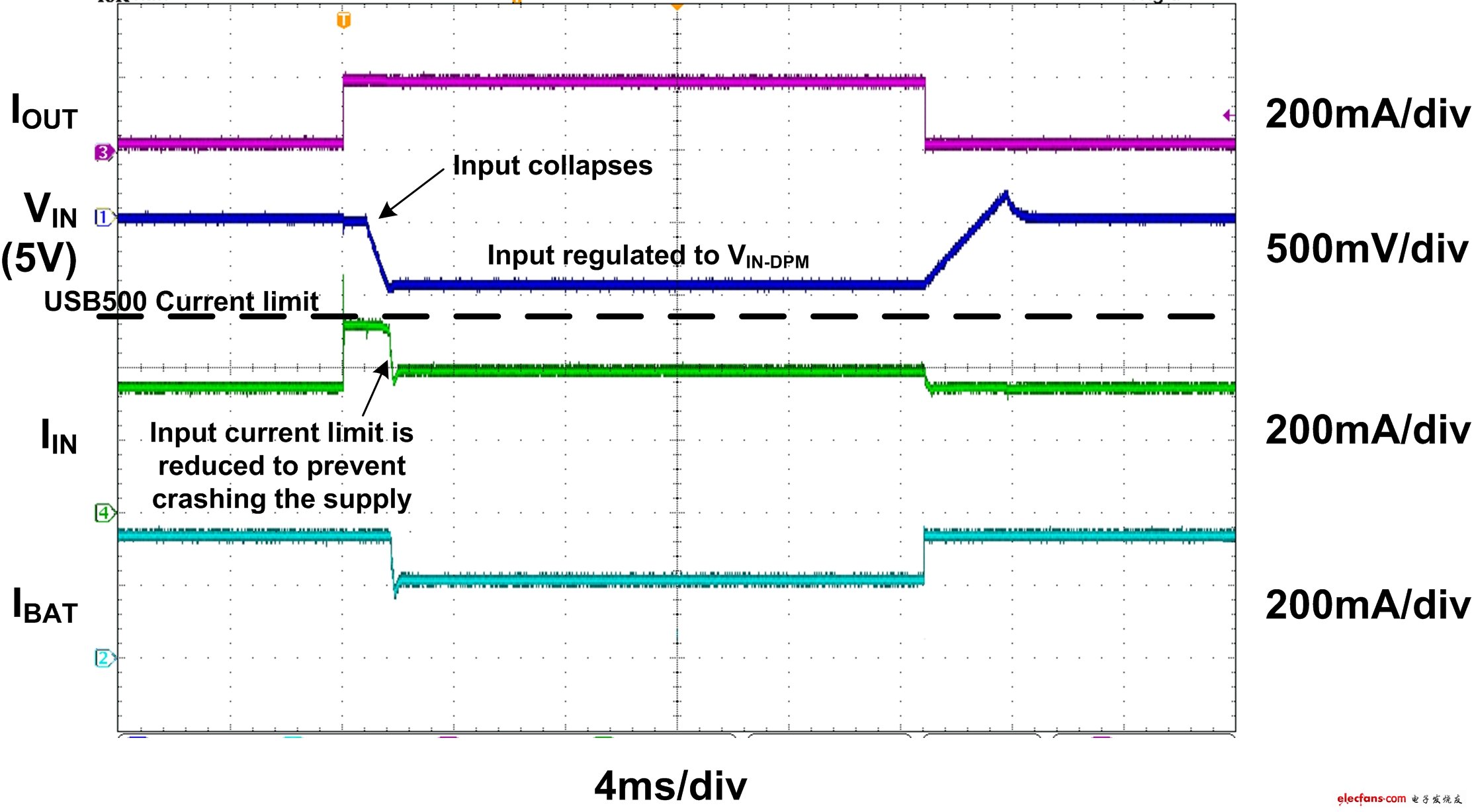

VIN-DPM 通過(guo)限制(zhi)輸(shu)入(ru)電流阻止脈沖發生(sheng),從(cong)而(er)(er)防止輸(shu)入(ru)源崩(beng)潰(kui)。圖5 顯(xian)示了超負載USB 端口的結(jie)果(guo)。VIN-DPM 功能開始生(sheng)效,降低輸(shu)入(ru)電流限制(zhi),從(cong)而(er)(er)防止輸(shu)入(ru)源崩(beng)潰(kui)。

圖(tu) 5 使(shi)用(yong)VIN-DPM的輸入超負載保護

NTC 監測(包括JEITA)

通過(guo)充電(dian)(dian)期間的監測防止電(dian)(dian)池(chi)組損壞甚至是爆炸時(shi),電(dian)(dian)池(chi)溫度極為重要。一(yi)般來(lai)(lai)說,通過(guo)對(dui)集成到電(dian)(dian)池(chi)組中或者靠近系統板上電(dian)(dian)池(chi)組安裝的NTC 熱敏電(dian)(dian)阻進(jin)行(xing)監測,來(lai)(lai)完成這項(xiang)工(gong)作。許多充電(dian)(dian)器都具(ju)有集成到IC 中的NTC 監測功能(neng)。如果電(dian)(dian)池(chi)溫度處在某些非安全(quan)溫度下時(shi),這些IC 便對(dui)溫度和禁用充電(dian)(dian)電(dian)(dian)流(liu)進(jin)行(xing)監測。

一種新興的電池充電標準是日本電池溫度標準 (JEITA)。這種標準規定了一些需降低充電電壓或者電流以提供更安全運行的中間溫度。該JEITA標準在許多充電器IC 中也很容易實施。例如,單輸入單體鋰離子電池充電器集成了一(yi)種無需主(zhu)機關聯的(de)獨(du)立解決(jue)方案(an)。對于NTC 受主(zhu)機監測的(de)系(xi)統來說,許多IC 都提供了非常簡單的(de)實施。I2C 接口(kou)允(yun)許用戶動態地改(gai)變充電(dian)(dian)電(dian)(dian)壓和充電(dian)(dian)電(dian)(dian)流,使用具有(you)這種接口(kou)的(de)充電(dian)(dian)器(qi)時(shi),主(zhu)機根(gen)據(ju)電(dian)(dian)池溫(wen)度來修改(gai)充電(dian)(dian)參數。這種方法在(zai)沒有(you)硬(ying)件改(gai)動的(de)情況下,在(zai)為不同平臺和電(dian)(dian)池設置要求的(de)溫(wen)度閾(yu)值(zhi)方面(mian)擁有(you)一(yi)定的(de)靈活性。

USB 充電標(biao)準

USB 充電時,可以使用許多充電器IC,它們(men)都結合了USB100和USB500 電流(liu)限(xian)制。通過(guo)USB 充電器(qi)輸出(chu)運行(xing)所有(you)下游電路,讓廣(guang)大設計人員能夠確保不超出(chu)USB 電流(liu)限(xian)制。

額外功率輸出

隨著USB 充電的流行,許多應用都要求一個USB PHY 或者USB 收發器與主機枚舉。因此,這些器件通常直接連接到VBUS 電源,從而要求過電壓保護。因此,許多充電器IC 都集成了一個連(lian)接電(dian)(dian)源(yuan)并通(tong)過電(dian)(dian)源(yuan)供電(dian)(dian)的5V LDO。每當連(lian)接一個有(you)效電(dian)(dian)源(yuan)時,這(zhe)種輸出便(bian)有(you)效。5V LDO 穩(wen)壓電(dian)(dian)壓保護(hu)USB 電(dian)(dian)路免受未(wei)穩(wen)壓適配器和(he)其他過電(dian)(dian)壓狀態的損(sun)害(hai)。

為單體鋰離子電池充電有很多種方法。我們必須對諸如充電電流、可用空間、USB 標準、成本和特性集等要求進行研究,以選擇最佳的解決方案。首先按照重要程度把這些要求排列出來,然后選擇最適合這些要求的拓撲結構。請一定要考慮散熱因素,最后為每種輸出選擇最具成本效益的解決方案。在這些簡單步驟之后,您的電池充電器設計(ji)應該(gai)就會變得簡單(dan)了(le)。