新型IC組成的鋰電池充電器方案

隨著手機、MP3、PMP、DC/DV等手持電子產品越來越大眾化,鋰金屬(Li)和鋰電池使用越來越普遍,而配用的充電器無論是市售的15元手機充電器還是較高檔的DC/DV兼容充電器,絕(jue)大部分是采用(yong)LM324組(zu)成的(de)充(chong)電(dian)(dian)電(dian)(dian)壓檢測和控制線路,這些線路無(wu)論從控制精度(du)還是功能(neng)方面都(dou)不能(neng)滿足鋰電(dian)(dian)池充(chong)電(dian)(dian)特(te)性的(de)要(yao)求,直接導致電(dian)(dian)池充(chong)不滿,電(dian)(dian)池壽(shou)命減短以及越來越多(duo)的(de)電(dian)(dian)池損壞、爆炸等案例發生。而如果采用(yong)國(guo)外專用(yong)IC來設計,則其(qi)極其(qi)高昂的(de)成本實在令人無(wu)法接受。

有鑒于此,筆者在此介紹兩款由國產新型IC組成的鋰電池充電器,在大(da)致(zhi)相當的(de)總體成本(ben)下提(ti)供了(le)遠遠超過LM324方案的(de)性(xing)能(neng),具有極高的(de)新穎性(xing)和市場前(qian)景。

PT7M7433T是上(shang)海百利通(tong)公司最新設計的(de)(de)極高精度的(de)(de)一系(xi)列電(dian)壓檢(jian)測器的(de)(de)其(qi)(qi)中(zhong)一款,其(qi)(qi)檢(jian)測精度在0-Vcc (5.5V)范(fan)圍內小(xiao)于1mV,而且(qie)其(qi)(qi)批量IC的(de)(de)檢(jian)測值(zhi)偏差<±2.5%,這(zhe)樣完全保證了批量產品(pin)的(de)(de)性(xing)能一致性(xing)和極高的(de)(de)總體(ti)性(xing)能,我們(men)利用其(qi)(qi)配合少量外部電(dian)路即可組成相當簡單的(de)(de)鋰電(dian)池充電(dian)線路。

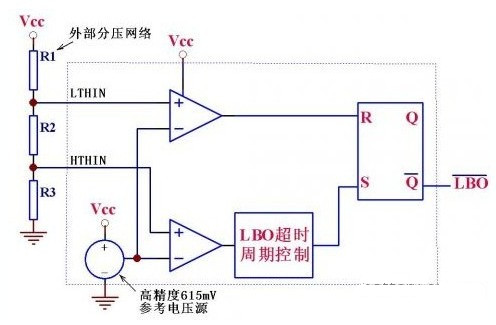

該(gai)IC的(de)內部框圖和簡(jian)單介紹(shao)如下:(圖一)

IC內含一個(ge)高(gao)精度的615mV基準(zhun)電(dian)壓(ya)(ya)源、兩個(ge)比(bi)較(jiao)器、一個(ge)RS觸發器和其它(ta)一些邏(luo)輯電(dian)路,其大致(zhi)功能是:VCC電(dian)壓(ya)(ya)或其它(ta)待(dai)檢(jian)測電(dian)壓(ya)(ya)通(tong)過R1-R3組成的分壓(ya)(ya)網絡(luo)接(jie)在IC的LTHIN /HTHIN檢(jian)測引(yin)腳(jiao),當待(dai)測電(dian)壓(ya)(ya)下降導致(zhi)LTHIN引(yin)腳(jiao)低(di)于(yu)615mV時(shi),輸(shu)出腳(jiao)LBO輸(shu)出低(di)電(dian)平(ping),而如(ru)果待(dai)測電(dian)壓(ya)(ya)上升導致(zhi)HTHIN引(yin)腳(jiao)高(gao)于(yu)615 mV時(shi),經過內部邏(luo)輯判(pan)斷(duan)和簡單延(yan)時(shi)后(hou),輸(shu)出腳(jiao)LBO輸(shu)出高(gao)電(dian)平(ping)。

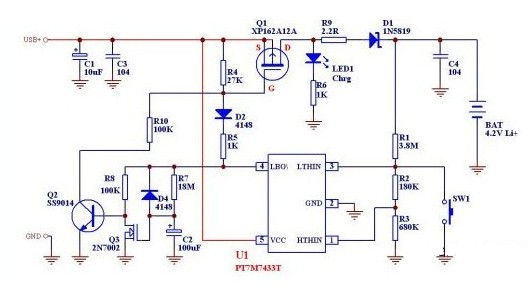

利用(yong)這個IC裝制(zhi)的充電器電路如下(圖二)

其(qi)工作流(liu)程(cheng)大(da)(da)致是(shi)(shi):當接上(shang)Li+電(dian)(dian)(dian)池和(he)供電(dian)(dian)(dian)電(dian)(dian)(dian)源時(shi)(shi),IC通(tong)(tong)(tong)過R1/R2/R3組(zu)成的(de)(de)(de)網(wang)絡檢測電(dian)(dian)(dian)池電(dian)(dian)(dian)壓(ya)(ya)(ya),如果電(dian)(dian)(dian)池電(dian)(dian)(dian)壓(ya)(ya)(ya)低(di)(di)于(yu)3.3V(由(you)R1-R3的(de)(de)(de)電(dian)(dian)(dian)阻值(zhi)決定),或者按(an)下按(an)制SW1,此(ci)時(shi)(shi)IC3腳(jiao)(jiao)的(de)(de)(de)電(dian)(dian)(dian)壓(ya)(ya)(ya)低(di)(di)于(yu)615mV,則IC4腳(jiao)(jiao)輸出低(di)(di)電(dian)(dian)(dian)平,通(tong)(tong)(tong)過R5/D2拉(la)低(di)(di)Q1的(de)(de)(de)柵(zha)極(ji)使(shi)之導通(tong)(tong)(tong),從(cong)而(er)通(tong)(tong)(tong)過Q1/R9/D1給電(dian)(dian)(dian)池進行大(da)(da)電(dian)(dian)(dian)流(liu)充(chong)電(dian)(dian)(dian),當電(dian)(dian)(dian)池電(dian)(dian)(dian)壓(ya)(ya)(ya)一路上(shang)升直(zhi)至(zhi)超過4.20V,此(ci)時(shi)(shi)IC的(de)(de)(de)1腳(jiao)(jiao)電(dian)(dian)(dian)壓(ya)(ya)(ya)高(gao)過615mV,IC內部經簡(jian)單判斷(duan)和(he)延時(shi)(shi),令(ling)4腳(jiao)(jiao)輸出高(gao)電(dian)(dian)(dian)平,從(cong)而(er)關閉大(da)(da)電(dian)(dian)(dian)流(liu)充(chong)電(dian)(dian)(dian)通(tong)(tong)(tong)道,但(dan)是(shi)(shi)4腳(jiao)(jiao)的(de)(de)(de)高(gao)電(dian)(dian)(dian)平同(tong)時(shi)(shi)給R7/C2的(de)(de)(de)充(chong)電(dian)(dian)(dian)回路供電(dian)(dian)(dian),令(ling)到Q3的(de)(de)(de)柵(zha)極(ji)電(dian)(dian)(dian)壓(ya)(ya)(ya)慢(man)慢(man)升高(gao),并給R8提供通(tong)(tong)(tong)路導致Q2導通(tong)(tong)(tong),通(tong)(tong)(tong)過R10給Q1提供一個較弱的(de)(de)(de)導通(tong)(tong)(tong)電(dian)(dian)(dian)流(liu),使(shi)之微(wei)微(wei)導通(tong)(tong)(tong),從(cong)而(er)為電(dian)(dian)(dian)池提供一個較少的(de)(de)(de)補充(chong)充(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流(liu)。按(an)照圖中所示元件(jian)參(can)數將(jiang)于(yu)大(da)(da)約十分鐘后,由(you)于(yu)C2的(de)(de)(de)不(bu)斷(duan)充(chong)電(dian)(dian)(dian),其(qi)端電(dian)(dian)(dian)壓(ya)(ya)(ya)即Q3的(de)(de)(de)柵(zha)極(ji)電(dian)(dian)(dian)壓(ya)(ya)(ya)不(bu)斷(duan)上(shang)升直(zhi)至(zhi)使(shi)Q3導通(tong)(tong)(tong),從(cong)而(er)關閉Q2,令(ling)到整(zheng)個充(chong)電(dian)(dian)(dian)過程(cheng)結束(shu)。

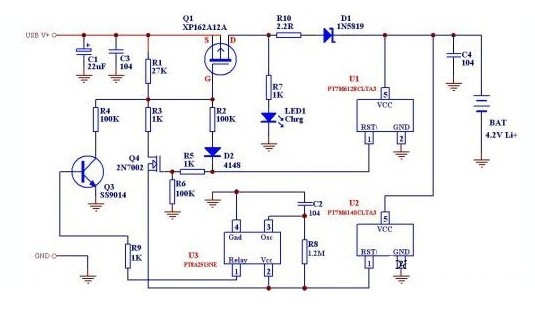

上面的方(fang)案還存在一(yi)些不足之處,例如檢測(ce)精度由外接電(dian)阻R1/R2/R3的精度決(jue)定,對于(yu)(yu)過放電(dian)的電(dian)池(chi)(電(dian)池(chi)端電(dian)壓低(di)于(yu)(yu)2.8V)沒有一(yi)個小電(dian)流預充(chong)的過程(cheng),另外該方(fang)案的10分鐘(zhong)補(bu)充(chong)充(chong)電(dian)時(shi)間對于(yu)(yu)較大容(rong)量的電(dian)池(chi)來(lai)說不是(shi)太足夠,因此針(zhen)對上述(shu)不足之處,我們(men)還提供一(yi)個成本稍高一(yi)點(dian),性(xing)能更(geng)加完善(shan)的方(fang)案:(圖三)

乍看之(zhi)下,這個(ge)方(fang)案(an)采(cai)(cai)用(yong)(yong)了三(san)個(ge)IC,可(ke)是(shi)U1和(he)(he)U2是(shi)采(cai)(cai)用(yong)(yong)的(de)SOT-23或者TO-92封裝,就好像普(pu)通三(san)極管一(yi)樣,其價格也(ye)就是(shi)2-3個(ge)三(san)極管的(de)價格,而U3(PT8A2513NE)也(ye)是(shi)采(cai)(cai)用(yong)(yong)的(de)TO-94封裝,外(wai)形和(he)(he)三(san)極管很(hen)相似,價錢也(ye)相當便宜,不過(guo),這個(ge)電(dian)(dian)(dian)路可(ke)以實現智能(neng)判斷電(dian)(dian)(dian)池是(shi)否過(guo)放電(dian)(dian)(dian),決(jue)定是(shi)否在開(kai)始充(chong)電(dian)(dian)(dian)時(shi)采(cai)(cai)用(yong)(yong)小(xiao)電(dian)(dian)(dian)流預(yu)充(chong),另(ling)外(wai),采(cai)(cai)用(yong)(yong)U3后也(ye)將充(chong)電(dian)(dian)(dian)后期的(de)補充(chong)充(chong)電(dian)(dian)(dian)過(guo)程延(yan)長到大約(yue)一(yi)個(ge)小(xiao)時(shi)!

首(shou)先(xian)讓我們介紹(shao)一(yi)下該電路中幾個IC的功能:

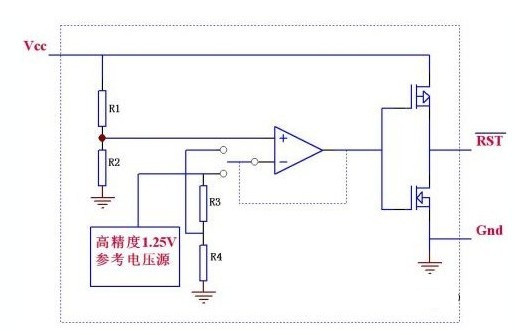

(圖四)是(shi)U1/U2的(de)(de)內部(bu)(bu)框圖,這兩個IC只是(shi)內部(bu)(bu)電(dian)阻R1/R2的(de)(de)數值不(bu)(bu)同(tong)(tong)而已,它(ta)們的(de)(de)功能也很(hen)簡單:當(dang)Vcc低于(yu)(yu)IC的(de)(de)設定值時(根據IC編號不(bu)(bu)同(tong)(tong),內部(bu)(bu)R3/R4阻值也不(bu)(bu)同(tong)(tong)從而導致檢測(ce)電(dian)壓值不(bu)(bu)同(tong)(tong),對(dui)于(yu)(yu)PT7M6128指的(de)(de)是(shi)2.80V),RST引(yin)腳(jiao)輸(shu)出低電(dian)平,反之當(dang)Vcc 高(gao)于(yu)(yu)1.05倍標稱值時(例如對(dui)于(yu)(yu)PT7M6140,此數值為1.05x4.0 =4.20V)則RST引(yin)腳(jiao)輸(shu)出高(gao)電(dian)平。

上(shang)面(mian)電路的(de)另外一(yi)個(ge)IC(PT8A25 13)則是(shi)(shi)一(yi)個(ge)極(ji)簡(jian)單卻極(ji)穩定(ding)的(de)延(yan)時IC,其延(yan)時時間(jian)僅僅取決于 OSC腳的(de)頻率。事實上(shang)該(gai)IC就是(shi)(shi)將OSC震(zhen)蕩頻率進行32768次分(fen)頻后用(yong)來(lai)控制(zhi)輸(shu)出的(de)。之所以(yi)采(cai)用(yong)這個(ge)電路而不(bu)采(cai)用(yong)LM555或者(zhe)CD4060等通用(yong)IC的(de)原因就是(shi)(shi)因為它(ta)相(xiang)對而言定(ding)時精度更高(其它(ta)IC不(bu)分(fen)頻),定(ding)時時間(jian)更長(可達數小時)。并(bing)且(qie)電路更加簡(jian)單,采(cai)用(yong)TO-94或SOT-23-4封裝,就像一(yi)個(ge)三極(ji)管一(yi)樣。而價錢也(ye)跟CD4060差(cha)不(bu)多(duo),使用(yong)效果可就好的(de)太多(duo)了。

至此大家想必也大致了解了圖三的工作流程了:接上電池和充電器,如果電池電壓低于2.8V,則U1輸出為低(U2輸出也是低),這樣R3和R4的回路都不通,只有R2回路導通,給Q1提供微弱的導通,使之輸出約數毫安的電流給電池進行預充電,當電池電壓上升到超過2.94V(1.05X2.8)時或者剛接上電池電壓就超過2.94V時,U1輸出高電平而U2繼續輸出低電平(電池電壓還沒達到4.2V J),這時R2通路截止而R3通路導通(因為Q4導通且其源極電平為低-因U1輸出拉低),從而由較小阻值的R3令Q1完全導通,提供一個數百毫安的大電流恒流充電,而當這個恒流充電過程慢慢令到被充電的Li+電池端電壓上升到4.2V時,U2也輸出高電平從而關閉Q4,但是它同時也給U3提供了電源導致U3開始工作,這樣U3觸發Q3使R4導通提供一個很小的補充充電電流,直至U3達到定時時間從而關閉Q3,這時整個充電過程才完全結束。

相比而言,第二個方案增加了前期智能判斷電池狀態和自動預充電過程,以及延長了末尾的補充充電過程的時間,各個階段的充電電流可調并且補充充電時間可調(數分鐘至數小時),因此該方案對鋰電池充電具有更好的精確性和安全性,加上價錢便宜,功能也比較完善,相信很快會取代市面中低檔的充電器特別是那些廉價的手機電池充電器。