電動車36V鋰電池組保護電路設計方案

隨著電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)自(zi)行車(che)(che)的(de)(de)(de)(de)(de)逐漸普及(ji),電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)自(zi)行車(che)(che)的(de)(de)(de)(de)(de)主(zhu)要能(neng)源---鋰電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)也(ye)成(cheng)為(wei)眾人關心(xin)的(de)(de)(de)(de)(de)焦點(dian)。 鋰電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)與(yu)鎳鎘、鎳氫(qing)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)不(bu)太一樣,因其能(neng)量密度高(gao),對充(chong)放電(dian)(dian)(dian)(dian)(dian)(dian)要求很高(gao)。 當過(guo)(guo)充(chong)、過(guo)(guo)放、過(guo)(guo)流及(ji)短路保(bao)(bao)護(hu)(hu)(hu)等情況發生時,鋰電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)內(nei)的(de)(de)(de)(de)(de)壓力與(yu)熱(re)量大量增加,容易產生爆炸,因此通常都會在電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)包(bao)內(nei)加保(bao)(bao)護(hu)(hu)(hu)電(dian)(dian)(dian)(dian)(dian)(dian)路,用(yong)(yong)(yong)以提高(gao)鋰電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)的(de)(de)(de)(de)(de)使用(yong)(yong)(yong)壽(shou)命。 針對目前(qian)電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)車(che)(che)鋰電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)組(zu)所用(yong)(yong)(yong)的(de)(de)(de)(de)(de)保(bao)(bao)護(hu)(hu)(hu)電(dian)(dian)(dian)(dian)(dian)(dian)路大多都由分(fen)立(li)原件構成(cheng),存在控(kong)制(zhi)精度不(bu)夠高(gao)、技術(shu)指(zhi)標低、不(bu)能(neng)有效保(bao)(bao)護(hu)(hu)(hu)鋰電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)組(zu)等特點(dian),本(ben)文中提出一種(zhong)基于單(dan)(dan)片機(ji)的(de)(de)(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)車(che)(che)36 V鋰電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)組(zu)(由10節3. 6 V鋰電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)串聯而成(cheng))保(bao)(bao)護(hu)(hu)(hu)電(dian)(dian)(dian)(dian)(dian)(dian)路設計方案,利用(yong)(yong)(yong)高(gao)性能(neng)、低功耗的(de)(de)(de)(de)(de)ATmega16L 單(dan)(dan)片機(ji)作為(wei)檢測和(he)控(kong)制(zhi)核心(xin),用(yong)(yong)(yong)由MC34063構成(cheng)的(de)(de)(de)(de)(de)DC /DC變換控(kong)制(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)路為(wei)整(zheng)個(ge)保(bao)(bao)護(hu)(hu)(hu)電(dian)(dian)(dian)(dian)(dian)(dian)路提供穩壓電(dian)(dian)(dian)(dian)(dian)(dian)源,輔以LM60 測溫、MOS管IRF530N作充(chong)放電(dian)(dian)(dian)(dian)(dian)(dian)控(kong)制(zhi)開關,實現對整(zheng)個(ge)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)組(zu)和(he)單(dan)(dan)個(ge)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)的(de)(de)(de)(de)(de)狀(zhuang)態監(jian)控(kong)和(he)保(bao)(bao)護(hu)(hu)(hu)功能(neng),達(da)到延(yan)長電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)使用(yong)(yong)(yong)壽(shou)命的(de)(de)(de)(de)(de)目的(de)(de)(de)(de)(de)。

1 保護電路硬件設計

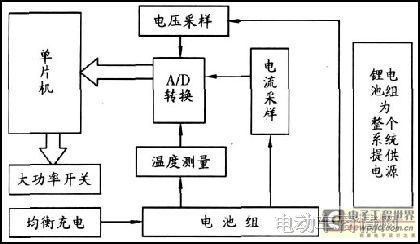

本系統(tong)(tong)以單片(pian)機(ji)為數(shu)據處理和控制的(de)核心,將任務設計分解為電壓測(ce)量、電流測(ce)量、溫度測(ce)量、開關控制、電源、均衡充電等功能(neng)模(mo)塊。 系統(tong)(tong)的(de)總體框圖(tu)(tu)如圖(tu)(tu)1所(suo)示。

圖1 系統的(de)總體框(kuang)圖

電池(chi)組(zu)電壓(ya)、電流、溫度等信(xin)(xin)息通過電壓(ya)采樣、電流采樣和(he)(he)(he)溫度測量(liang)電路,加到信(xin)(xin)號采集部分的A /D輸(shu)入(ru)端。 A /D模(mo)塊將輸(shu)入(ru)的模(mo)擬信(xin)(xin)號轉換為數(shu)字信(xin)(xin)號,并(bing)傳輸(shu)給單(dan)(dan)片(pian)機(ji)。 單(dan)(dan)片(pian)機(ji)作(zuo)為數(shu)據處理和(he)(he)(he)控制的核心(xin),一方面實時監(jian)控電池(chi)組(zu)的各項性(xing)(xing)能(neng)指標和(he)(he)(he)狀態,一方面根據這(zhe)些狀態參數(shu)控制驅(qu)動(dong)大功率開關。 由于(yu)使用了單(dan)(dan)片(pian)機(ji),使系統具有很大的靈活(huo)性(xing)(xing),便于(yu)實現各種復雜(za)控制,從而能(neng)方便地(di)對(dui)系統進行功能(neng)擴展和(he)(he)(he)性(xing)(xing)能(neng)改進。

1. 1 ATmega16 L單片機模塊

從低功耗、低成本設計角度出發,單片機模塊采用高性能、低功耗的ATmega16 L單片機作為檢測與控制核心。 ATmega16 L 是基于增強的AVRR ISC結構的低功耗8位CMOS微控制器,內部帶有16 k 字節的系統內可編程Flash, 512 字節EEPROM, 1 k字節SRAM, 32個通用I/O口線, 32個通用工作寄存器(用于邊界掃描的JTAG接口,支持片內調試與編程) , 3個具有比較模式的靈活定時器/計數器( T/C) (片內/外中斷) ,可編程串行USART,有起始條件檢測器的通用串行接口, 8路10位具有可選差分輸入級可編程增益( TQFP封裝)的ADC,具有片內振蕩器的可編程看門狗定時器,一個SP I串行端口,以及6個可以通過軟件進行選擇的省電模式。 由于其先進的指令集以及單時鐘周期指令執行時間,ATmega16 L的數據吞吐率高達1M IPS/MHz,從而可以緩減系統功耗和處理速度之間的矛盾。

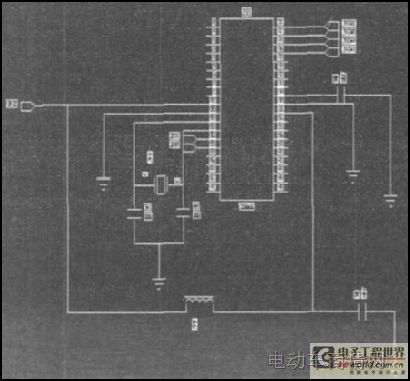

單片機的輸入輸出設計如圖2所示。 由電源部分降壓、穩壓得到的3. 3 V電壓通過端口10為單片機提供工作電壓;端口12和13為反向振蕩放大器與片內時鐘操作電路的輸入端和反向振蕩放大器的輸出端,為單片機提供工作晶振;端口30是端口A與A /D轉換器的電源,使用ADC時通過一個低通濾波器與端口10的VCC連接;端口37,38的ADC3, ADC2是經過轉換后待檢測的電壓、電流值;端口39, 40的ADC1,ADC0是經過溫度傳感器轉換后的溫控電壓值。

圖2 單(dan)片機的(de)外圍電(dian)路設計

1. 2 穩壓電源模塊

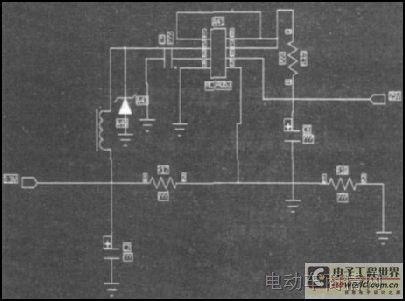

穩壓電源是單片機系統的重要組成部分,它不僅為系統提供多路電源電壓,還直接影響到系統的技術指標和抗干擾性能。 ATmega16 L單片機的工作電壓為2. 7~5. 5 V,為保證單片機穩定的工作電壓為3. 3 V. 穩壓部分是由MC34063構成的DC /DC變換控制電路,從電池組分出的25 V電壓經過電路降壓、穩壓,輸出3. 3 V,供保護電路工作,其電路如圖3所示。

圖(tu)3 穩壓電源模(mo)塊電路

1. 3 充電均衡模塊

采用模擬電路方案。 即在每節電池的外部搭建過壓保護電路,充電過程中當電壓超過預定值時,保護電路自動閉合,使電池通過電阻回路放電,以保護電池不會過度充電。 當電池電壓減小到均衡充電動作電壓4. 18 V時,保護電路自動斷開。

1. 4 電壓電流測量模塊

待測的電壓通過集成運算放大器LM358,將輸出送至單片機進行檢測。 LM358內部包括2個獨立、高增益、內部頻率補償的雙運算放大器,適合于電源電壓范圍很寬的單電源使用和雙電源工作模式,由于其低功耗電流,也適合于電池。 用霍爾傳感器UGN - 3501 M 檢測直流電流。 UGN -3501M是集成型霍爾傳感器,采用差動霍爾電壓輸出,檢測靈敏度為1. 4 V /0. 1T.

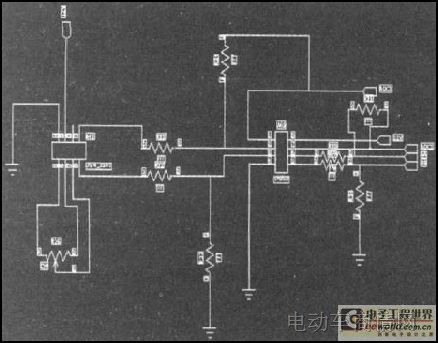

電(dian)(dian)(dian)壓(ya)電(dian)(dian)(dian)流(liu)(liu)檢(jian)(jian)測(ce)(ce)電(dian)(dian)(dian)路的(de)(de)(de)設計如(ru)圖(tu)4 所示(shi)。 運算放大器LM358的(de)(de)(de)5, 6引腳所接(jie)(jie)的(de)(de)(de)BB,AA為待測(ce)(ce)的(de)(de)(de)充電(dian)(dian)(dian)、放電(dian)(dian)(dian)電(dian)(dian)(dian)壓(ya),經過(guo)放大后由(you)7腳輸出(chu)至(zhi)單(dan)(dan)(dan)片機進行檢(jian)(jian)測(ce)(ce),當(dang)檢(jian)(jian)測(ce)(ce)到待測(ce)(ce)電(dian)(dian)(dian)壓(ya)達到過(guo)充、過(guo)放保護(hu)電(dian)(dian)(dian)壓(ya)時(shi),由(you)單(dan)(dan)(dan)片機控制(zhi)斷開(kai)充放電(dian)(dian)(dian)回路。 電(dian)(dian)(dian)流(liu)(liu)檢(jian)(jian)測(ce)(ce)通(tong)過(guo)霍(huo)爾傳感器完(wan)成,如(ru)圖(tu)4所示(shi),將從(cong)UGN -3501M1, 8引腳輸出(chu)的(de)(de)(de)霍(huo)爾電(dian)(dian)(dian)壓(ya)uH 接(jie)(jie)至(zhi)LM358的(de)(de)(de)3, 4引腳,經過(guo)放大后從(cong)1 腳輸出(chu)ADC3 至(zhi)單(dan)(dan)(dan)片機,進行過(guo)電(dian)(dian)(dian)流(liu)(liu)保護(hu)。 UGN - 3501M 的(de)(de)(de)5, 6, 7引腳連接(jie)(jie)調(diao)整電(dian)(dian)(dian)位(wei)器,用以補償不等位(wei)電(dian)(dian)(dian)勢,同(tong)時(shi)改(gai)善線性。 調(diao)整5, 6引腳外接(jie)(jie)電(dian)(dian)(dian)阻R16,可(ke)使輸出(chu)霍(huo)爾電(dian)(dian)(dian)壓(ya)uH 與磁場強度有較(jiao)好的(de)(de)(de)線性關系(xi)。

圖4 電壓電流檢測電路

1. 5 溫度檢測模塊

溫度檢測和控制模塊選用電壓輸出型的半導體溫度傳感器LM60. 該傳感器是一種已校正的集成化溫度傳感器,它的工作溫度范圍是- 40 ℃至125 ℃,工作電壓范圍是2. 7 V至10 V. 信號輸出與溫度成正比,信號大小可達+ 6. 25 mV /℃。

基于(yu)LM60的(de)溫(wen)度(du)檢(jian)測(ce)電(dian)(dian)路(lu)如圖(tu)5所示。 由穩壓(ya)部分(fen)輸出的(de)3. 3 V 電(dian)(dian)源(yuan)為(wei)此電(dian)(dian)路(lu)供電(dian)(dian),經過溫(wen)度(du)傳(chuan)感器將探(tan)測(ce)點的(de)溫(wen)度(du)轉化為(wei)電(dian)(dian)壓(ya)值通(tong)過ADC0,ADC1輸出,再將ADC0, ADC1送入單(dan)片機進行(xing)檢(jian)測(ce),當(dang)電(dian)(dian)壓(ya)值達到(dao)溫(wen)控要求(qiu)時,單(dan)片機控制(zhi)開(kai)關通(tong)斷。

圖(tu)5 溫度檢測電路

1. 6 開關模塊

開關采用MOSFET,型號選用P溝道的MOS管的IR530N. 工作原理:單片機控制端口輸出高電平,功率三極管導通,功率場效應管的柵極和漏極之間產生壓降,功率場效應管導通。

2 軟件設計

本系統軟件采用C語言編寫,處理程(cheng)序采用模塊化編程(cheng), 程(cheng)序運行的環境是(shi)ICCAVR 開發系統。

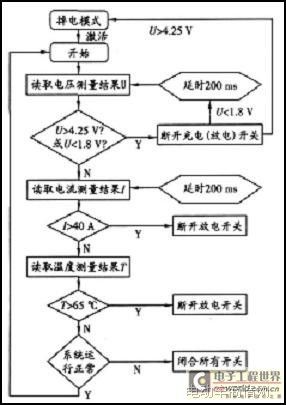

在(zai)電池(chi)組(zu)空(kong)載的時(shi)候,系統進入(ru)掉電模(mo)式(shi)(shi)(shi),以使(shi)功耗降至最低(di);當電池(chi)組(zu)接入(ru)負(fu)載或對電池(chi)組(zu)充電時(shi),單片機被激活(huo),由低(di)功耗掉電模(mo)式(shi)(shi)(shi)轉入(ru)正常工作(zuo)模(mo)式(shi)(shi)(shi),并持(chi)續運作(zuo)。 整個程序的流程如圖6所示。

圖(tu)6 程序流程

根據(ju)本系統的(de)(de)模(mo)(mo)塊(kuai)分布,單片機程(cheng)序(xu)分為電(dian)(dian)壓測量模(mo)(mo)塊(kuai)、電(dian)(dian)流測量模(mo)(mo)塊(kuai)和溫(wen)度(du)測量模(mo)(mo)塊(kuai),每(mei)一(yi)模(mo)(mo)塊(kuai)調用(yong)共同A /D轉(zhuan)換函(han)數和延時判斷函(han)數等,以縮短代碼長度(du)和增強程(cheng)序(xu)代碼的(de)(de)可讀性。 下(xia)面給出程(cheng)序(xu)主函(han)數的(de)(de)代碼:

void main (void)

{

int ( ) ; / /單片機初始化,打開所有開關;

sleep ( ) ; / /單片機進入休眠模式;

int sign |= 1;

while ( sign = = 1 ) / /判斷系統是否運行正常;

{ int( ) ;

dianya ( ) ; / /調用測壓模塊;

delay(30000) ;

delay(30000) ;

dianliu ( ) ; / /調用測流模塊;

delay(30000) ;

delay(30000) ;

wendu ( ) ; / /調用溫度模塊;

delay(30000) ;

delay(30000) ;

}

int ( ) ;

sign |= 1;

main ( ) ;

}

3 結束語

通過實驗,本(ben)保(bao)護電(dian)路系(xi)統(tong)實現了全部基本(ben)功能。 與傳(chuan)統(tong)采用(yong)分離元件的電(dian)池保(bao)護系(xi)統(tong)相比,本(ben)文中(zhong)提出基于單片機的電(dian)池保(bao)護電(dian)路系(xi)統(tong)具(ju)有(you)系(xi)統(tong)體積小、功能多、功耗低、成(cheng)本(ben)低等特點,可用(yong)于工業生產。