智能型手機電源系統

當今(jin)科技所需求的(de)手機電(dian)池除了要能夠長(chang)(chang)時間供(gong)(gong)應穩定電(dian)源外,體積小重量(liang)輕也是(shi)關(guan)鍵。縮小電(dian)路板面積、增長(chang)(chang)供(gong)(gong)電(dian)時間與減少成(cheng)本該如何畢其功于一役?將眾多電(dian)源管理組(zu)件整合在單一芯片上將是(shi)解決問題的(de)最好途徑(jing)。

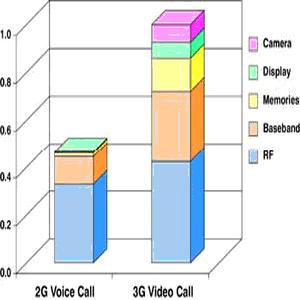

早期的(de)行(xing)動(dong)電(dian)(dian)(dian)(dian)(dian)話(hua)(hua)不是體積笨重龐大,就(jiu)是必須(xu)受到汽車電(dian)(dian)(dian)(dian)(dian)池的(de)束縛,但經過長時間的(de)發展,今(jin)天的(de)行(xing)動(dong)電(dian)(dian)(dian)(dian)(dian)話(hua)(hua)已變得非常輕巧,除了電(dian)(dian)(dian)(dian)(dian)話(hua)(hua)功(gong)能(neng)(neng),它(ta)們(men)還會做許(xu)多事。新型3.xG智能(neng)(neng)型手機(ji)把傳統的(de)2G行(xing)動(dong)電(dian)(dian)(dian)(dian)(dian)話(hua)(hua)和多種其(qi)它(ta)功(gong)能(neng)(neng)結合(he)在一起,包括PDA、數字(zi)相(xiang)機(ji)、音樂播放機(ji)(MP3)以及(ji)全球定位系統(GPS)。如此多元(yuan)的(de)功(gong)能(neng)(neng)需(xu)要許(xu)多零件,其(qi)中絕大多數的(de)電(dian)(dian)(dian)(dian)(dian)源電(dian)(dian)(dian)(dian)(dian)壓并不相(xiang)同(tong),電(dian)(dian)(dian)(dian)(dian)流需(xu)求(qiu)則不斷增(zeng)加(jia),使得它(ta)們(men)需(xu)要更多電(dian)(dian)(dian)(dian)(dian)力。(圖一)是從(cong)2G語音電(dian)(dian)(dian)(dian)(dian)話(hua)(hua)升級到3G視訊電(dian)(dian)(dian)(dian)(dian)話(hua)(hua)后,功(gong)率需(xu)求(qiu)增(zeng)加(jia)的(de)估計(ji)值(zhi)。

圖一功(gong)耗值

在(zai)(zai)此同時(shi),消費者卻想要(yao)更精巧(qiao)的(de)手(shou)機。本文介(jie)紹兩種電(dian)源管理系統,它們可以協(xie)助智能型手(shou)機設(she)計(ji)人員在(zai)(zai)彼(bi)此沖突的(de)目標間取(qu)得平衡,例如將封裝減至(zhi)最小,同時(shi)支持更大(da)的(de)功率(lv)(lv)需(xu)求;實(shi)現最佳效(xiao)率(lv)(lv),讓(rang)電(dian)池(chi)提供最長(chang)的(de)使(shi)用(yong)時(shi)間;以及將電(dian)源噪聲和(he)漣波降至(zhi)可接受水平,以支持新世代的(de)行動電(dian)話。

選擇電池

選擇充電電池是電源管理系統設計的首要工作之一,鎳氫電池和鋰離子電池則(ze)是目前僅有的(de)(de)兩種實際選擇(ze)。鋰離子電(dian)池的(de)(de)單位體積(ji)蓄電(dian)量(liang)為(wei)(wei)270~300Wh/l,單位重(zhong)量(liang)蓄電(dian)量(liang)為(wei)(wei)110~130Wh/kg,都(dou)高于(yu)鎳(nie)氫(qing)(qing)電(dian)池的(de)(de)220~300Wh/l以及75~100Wh/kg,因此在同樣蓄電(dian)量(liang)下(xia),鋰離子電(dian)池的(de)(de)體積(ji)和重(zhong)量(liang)都(dou)小于(yu)鎳(nie)氫(qing)(qing)電(dian)池;另外,鋰離子電(dian)池的(de)(de)3.6V工作電(dian)壓也高于(yu)鎳(nie)氫(qing)(qing)電(dian)池的(de)(de)1.2V。

行動(dong)電(dian)話的多數功耗(hao)都來(lai)自于1.2V和3.3V電(dian)源,要讓交換式電(dian)源轉(zhuan)換器發揮(hui)最大工作效率,較有效的方法(fa)通常(chang)是(shi)從(cong)高(gao)電(dian)壓轉(zhuan)換至(zhi)低電(dian)壓,而不是(shi)從(cong)低電(dian)壓轉(zhuan)換至(zhi)高(gao)電(dian)壓,因此鋰離子(zi)電(dian)池是(shi)最佳選擇(ze)。

要讓充電電池提供最長使用時間,適當的電池管理和控制就顯得格外重要。電池管理包含三個部份:充電控制、電池監視和電池保護。從使用外接導通組件的線性控制器開始,到內建開關組件且效率更高的交換式控制器,充電控制組件已有長足進步。電池充電器必須處(chu)理500mA到1500mA范圍內(nei)的(de)電(dian)流,以便提供快速(su)的(de)充電(dian)周期時間。

電(dian)(dian)(dian)池(chi)監視和(he)保護組(zu)件(jian)通常都與(yu)(yu)電(dian)(dian)(dian)池(chi)封裝(zhuang)在一(yi)起,電(dian)(dian)(dian)池(chi)監視組(zu)件(jian)可(ke)以是簡單(dan)的(de)「電(dian)(dian)(dian)荷計量器(qi)」(coulombcounter),由中(zhong)央(yang)處(chu)理器(qi)負責計算(suan)電(dian)(dian)(dian)池(chi)剩(sheng)余電(dian)(dian)(dian)力;也可(ke)以是內建微(wei)控制器(qi)的(de)電(dian)(dian)(dian)池(chi)電(dian)(dian)(dian)力量測組(zu)件(jian)(gasgauge),由它(ta)透過(guo)DSP與(yu)(yu)處(chu)理器(qi)之間(jian)的(de)簡單(dan)界面,直接提供剩(sheng)余電(dian)(dian)(dian)力、剩(sheng)余供電(dian)(dian)(dian)時(shi)間(jian)、電(dian)(dian)(dian)池(chi)電(dian)(dian)(dian)壓(ya)、溫度和(he)平(ping)均電(dian)(dian)(dian)流量測值(zhi)等資(zi)料。

電源(yuan)拓樸

接著,設(she)計工程師必須決(jue)定電(dian)源(yuan)轉(zhuan)換(huan)(huan)組件的(de)種(zhong)類,它或(huo)許是(shi)以(yi)電(dian)感(gan)為基(ji)礎、并且(qie)內建FET開關的(de)交換(huan)(huan)式(shi)電(dian)源(yuan)轉(zhuan)換(huan)(huan)器(qi)、無(wu)電(dian)感(gan)的(de)交換(huan)(huan)式(shi)電(dian)源(yuan)轉(zhuan)換(huan)(huan)器(qi)(電(dian)荷泵(beng)(beng)浦(pu))或(huo)是(shi)線(xian)性(xing)穩壓(ya)器(qi)。這些轉(zhuan)換(huan)(huan)器(qi)各(ge)有其優(you)點。就效(xiao)率(lv)而言,以(yi)電(dian)感(gan)為基(ji)礎的(de)轉(zhuan)換(huan)(huan)器(qi)擁有最(zui)高的(de)整體效(xiao)率(lv),其次是(shi)電(dian)荷泵(beng)(beng)浦(pu),最(zui)后才是(shi)線(xian)性(xing)穩壓(ya)器(qi)。成(cheng)(cheng)本(ben)通常反比于效(xiao)率(lv),因(yin)此線(xian)性(xing)穩壓(ya)器(qi)成(cheng)(cheng)本(ben)最(zui)低,然后是(shi)電(dian)荷泵(beng)(beng)浦(pu),最(zui)后則是(shi)以(yi)電(dian)感(gan)為基(ji)礎的(de)轉(zhuan)換(huan)(huan)器(qi)。

線(xian)(xian)性穩壓器(qi)沒有輸出(chu)(chu)漣(lian)(lian)波,電(dian)(dian)荷(he)泵浦(pu)有一些輸出(chu)(chu)漣(lian)(lian)波,交換式穩壓器(qi)的輸出(chu)(chu)漣(lian)(lian)波則在(zai)三者(zhe)之(zhi)間最高(gao)。就整個解決(jue)方(fang)案的體積來看,線(xian)(xian)性穩壓器(qi)的體積最小,通常只需輸入和(he)輸出(chu)(chu)電(dian)(dian)容,電(dian)(dian)荷(he)泵浦(pu)除了輸入和(he)輸出(chu)(chu)電(dian)(dian)容外,還需一顆或兩顆「飛馳」(flying)電(dian)(dian)容,交換式穩壓器(qi)則需要電(dian)(dian)感器(qi),因此其封裝體積會有很大差異。

無論DSP或(huo)模擬(ni)(ni)數字轉換器(qi)等數字零件(jian),或(huo)是電(dian)(dian)源管(guan)理(li)系(xi)(xi)統(tong)(tong)等模擬(ni)(ni)零件(jian),2G電(dian)(dian)話幾(ji)乎不提供任(ren)何的(de)(de)(de)功能(neng)(neng)整合,系(xi)(xi)統(tong)(tong)設計人員在發展電(dian)(dian)源管(guan)理(li)系(xi)(xi)統(tong)(tong)時,通(tong)常(chang)會以(yi)成本和體積為優先考慮,而不是轉換效(xiao)率。線(xian)性(xing)穩壓(ya)(ya)器(qi)只能(neng)(neng)將輸入電(dian)(dian)壓(ya)(ya)轉換成更低的(de)(de)(de)輸出電(dian)(dian)壓(ya)(ya),因此電(dian)(dian)池電(dian)(dian)壓(ya)(ya)必須高于(yu)3.3V,此時可利用低電(dian)(dian)流(liu)或(huo)中電(dian)(dian)流(liu)的(de)(de)(de)線(xian)性(xing)穩壓(ya)(ya)器(qi)進行電(dian)(dian)壓(ya)(ya)轉換,以(yi)便提供電(dian)(dian)力給至(zhi)2.8V范(fan)圍(wei)內(nei)的(de)(de)(de)其它(ta)電(dian)(dian)源需求。

在(zai)3G芯(xin)片組中,基頻(pin)處理器(qi)(qi)(qi)(qi)現已包含DSP、微(wei)(wei)處理器(qi)(qi)(qi)(qi)/微(wei)(wei)控制(zhi)器(qi)(qi)(qi)(qi)、模擬(ni)數字(zi)轉(zhuan)換(huan)器(qi)(qi)(qi)(qi)和(he)數字(zi)模擬(ni)轉(zhuan)換(huan)器(qi)(qi)(qi)(qi),用(yong)來控制(zhi)射頻(pin)訊號和(he)音頻(pin)訊號處理。這顆處理器(qi)(qi)(qi)(qi)的(de)核心電(dian)壓(ya)已降至1.2V或是更低,I/O和(he)外圍(wei)電(dian)壓(ya)也開始減(jian)少至2.5V至3.0V范圍(wei);由于3.xG電(dian)話(hua)的(de)電(dian)流需(xu)求通(tong)常都超過2.G電(dian)話(hua),3.xG設(she)計人員需(xu)要效率高于線性穩壓(ya)器(qi)(qi)(qi)(qi)的(de)直(zhi)流電(dian)源轉(zhuan)換(huan)器(qi)(qi)(qi)(qi),以便提供更長(chang)的(de)電(dian)池使用(yong)時間。為進(jin)一(yi)步(bu)延長(chang)電(dian)池壽命,許多(duo)設(she)計人員必須盡量利(li)用(yong)鋰(li)離子電(dian)池電(dian)力(li),直(zhi)到其(qi)電(dian)壓(ya)降至最小值為止;在(zai)此過程中,如何產生(sheng)3.3V電(dian)壓(ya)就變成一(yi)項挑戰。

從(cong)表(biao)面上來(lai)看,設計(ji)人員若能繼續(xu)使用(yong)(yong)(yong)電(dian)(dian)(dian)(dian)(dian)(dian)池直到2.7V,并利用(yong)(yong)(yong)正電(dian)(dian)(dian)(dian)(dian)(dian)源降壓(ya)―升壓(ya)轉換(huan)器或是SEPIC轉換(huan)器提供(gong)3.3V電(dian)(dian)(dian)(dian)(dian)(dian)源,可(ke)攜(xie)式(shi)裝置(zhi)的(de)(de)電(dian)(dian)(dian)(dian)(dian)(dian)池壽命就會大幅延長,但(dan)是根據(表(biao)一)針對600mAh電(dian)(dian)(dian)(dian)(dian)(dian)池所做的(de)(de)簡單分析可(ke)發現情形并非如此,因為無論是采(cai)用(yong)(yong)(yong)效率更高的(de)(de)降壓(ya)轉換(huan)器,并將電(dian)(dian)(dian)(dian)(dian)(dian)池使用(yong)(yong)(yong)到3.3V,或是采(cai)用(yong)(yong)(yong)SEPIC之類的(de)(de)轉換(huan)器,并將電(dian)(dian)(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)(dian)(dian)力完全用(yong)(yong)(yong)盡,這兩種方式(shi)的(de)(de)供(gong)電(dian)(dian)(dian)(dian)(dian)(dian)時(shi)間幾乎(hu)沒有任何區別。

表一60mAh電池(chi)分(fen)析

除此之外,無論(lun)是(shi)使(shi)用(yong)兩顆電(dian)感的(de)SEPIC轉(zhuan)換器(qi),或是(shi)某些效率更(geng)高(gao)的(de)新型正電(dian)源(yuan)(yuan)降壓―升(sheng)壓轉(zhuan)換器(qi),它們的(de)成本都更(geng)高(gao),因此在做(zuo)整(zheng)體(ti)評估時,只使(shi)用(yong)3.3V以上的(de)電(dian)池電(dian)力,然(ran)后(hou)利用(yong)高(gao)效率交換式(shi)電(dian)源(yuan)(yuan)轉(zhuan)換器(qi)提(ti)(ti)供(gong)3.3V電(dian)源(yuan)(yuan)的(de)方法不(bu)但更(geng)有效率,還可能是(shi)更(geng)具吸引力的(de)選擇。以下介紹的(de)離散解(jie)決(jue)方案(an)就是(shi)使(shi)用(yong)降壓轉(zhuan)換器(qi)提(ti)(ti)供(gong)3.3V電(dian)源(yuan)(yuan),整(zheng)合式(shi)解(jie)決(jue)方案(an)則采用(yong)SEPIC轉(zhuan)換器(qi)。

系統概述

不(bu)同(tong)的(de)智能型手(shou)機零件有著不(bu)同(tong)的(de)電(dian)源(yuan)需求(qiu),(圖二)是(shi)行動電(dian)話中(zhong)(zhong)需要(yao)電(dian)源(yuan)的(de)主要(yao)零件簡單(dan)方塊圖,例(li)如射頻單(dan)元的(de)壓控振蕩器(qi)(VCO)以及鎖相回路(PLL)就(jiu)需要(yao)極低噪聲(sheng)和很高(gao)電(dian)源(yuan)拒斥比的(de)電(dian)源(yuan),確保(bao)它們(men)提供(gong)最(zui)高(gao)的(de)傳送和接收效能,因此雖然線性穩壓器(qi)的(de)效率不(bu)高(gao),但由于(yu)它沒有輸(shu)出(chu)漣波,所以是(shi)這類(lei)電(dian)源(yuan)供(gong)應的(de)最(zui)佳選擇;同(tong)樣重(zhong)要(yao)的(de)是(shi)將直流轉換器(qi)的(de)開關頻率,還(huan)有它們(men)的(de)二階和三階諧波,都(dou)保(bao)持在中(zhong)(zhong)頻頻帶之外。

由于DSP和中(zhong)央處(chu)理器(qi)的(de)核心電(dian)(dian)(dian)壓已降(jiang)(jiang)(jiang)至1V左(zuo)右,以(yi)電(dian)(dian)(dian)感為基礎的(de)高效率(lv)交換(huan)式降(jiang)(jiang)(jiang)壓轉換(huan)器(qi)是理想(xiang)選擇(ze)。至于屏幕背光(guang)照明所使用的(de)白光(guang)二極管,其電(dian)(dian)(dian)源可來自電(dian)(dian)(dian)荷泵浦或電(dian)(dian)(dian)感式升壓/降(jiang)(jiang)(jiang)壓轉換(huan)器(qi)。

圖二智能型手(shou)機電源(yuan)方塊圖

動態(tai)電壓調整(DynamicVoltageScaling)

從(cong)圖一可看出,電源需(xu)求最高(gao)的(de)兩顆零件是在(zai)射(she)頻(pin)單元,分(fen)別是發(fa)射(she)機的(de)功(gong)率(lv)放大(da)器(qi)和基頻(pin)處理器(qi)。隨著(zhu)電話與(yu)基地臺之間的(de)距離不同,功(gong)率(lv)放大(da)器(qi)在(zai)通話過程(cheng)中最多消耗75%的(de)總功(gong)耗,待命模式則只(zhi)有(you)30%。采用(yong)非線性功(gong)率(lv)放大(da)器(qi)的(de)舊型(xing)GSM電話發(fa)射(she)機的(de)典型(xing)工作效率(lv)約為(wei)50%,但是WCDMA等較新標準卻(que)同時需(xu)要振幅及相位調變(bian),這只(zhi)有(you)工作效率(lv)在(zai)25%至35%之間的(de)線性放大(da)器(qi)可以提(ti)供。

除此之外,CDMA20001x手機的(de)正常基頻處理器(qi)負(fu)載(zai)需求(qiu)是在60至120mA范(fan)圍,因此提供最有效(xiao)率(lv)的(de)電源(yuan)給功率(lv)放大(da)器(qi)和處理器(qi)就顯得極(ji)為重要。

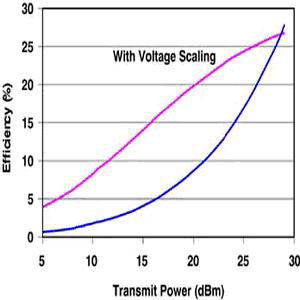

動態(tai)/可適(shi)性電壓調(diao)整(zheng)(zheng)(zheng)技(ji)術(shu)(DVS/AVS)與(yu)高整(zheng)(zheng)(zheng)合度(du)組件所使用的(de)(de)方式很類似(si),它(ta)(ta)(ta)會(hui)把閉回路系(xi)統中的(de)(de)處理(li)器(qi)和(he)穩壓器(qi)連結在(zai)一起,并在(zai)確保系(xi)統正常工(gong)作的(de)(de)情(qing)形(xing)下,將數(shu)字電源(yuan)供應(ying)的(de)(de)輸出電壓動態(tai)調(diao)整(zheng)(zheng)(zheng)至(zhi)最(zui)小值。功(gong)(gong)率(lv)(lv)放(fang)大(da)器(qi)會(hui)被最(zui)佳化,使它(ta)(ta)(ta)在(zai)最(zui)大(da)傳(chuan)送(song)功(gong)(gong)率(lv)(lv)下擁有最(zui)高效率(lv)(lv)。由(you)于絕大(da)多數(shu)手機都在(zai)基地(di)臺附近工(gong)作,手機的(de)(de)無線電功(gong)(gong)能會(hui)在(zai)維(wei)持通訊質(zhi)量(liang)的(de)(de)前題(ti)下,將傳(chuan)送(song)功(gong)(gong)率(lv)(lv)降(jiang)至(zhi)最(zui)低(di)水(shui)平(ping)。當功(gong)(gong)率(lv)(lv)放(fang)大(da)器(qi)在(zai)較(jiao)低(di)的(de)(de)功(gong)(gong)率(lv)(lv)水(shui)平(ping)下工(gong)作時,它(ta)(ta)(ta)的(de)(de)效率(lv)(lv)會(hui)受到影(ying)響,從(圖三)可以看出,利(li)用動態(tai)電壓調(diao)整(zheng)(zheng)(zheng)技(ji)術(shu)來調(diao)整(zheng)(zheng)(zheng)功(gong)(gong)率(lv)(lv)放(fang)大(da)器(qi)的(de)(de)電壓,它(ta)(ta)(ta)的(de)(de)工(gong)作效率(lv)(lv)會(hui)增(zeng)加10%至(zhi)20%。

圖三功(gong)率(lv)放大器效率(lv)

數字處理(li)(li)(li)器(qi)的(de)功(gong)(gong)耗正比(bi)于電(dian)壓(ya)平方,因(yin)此中央(yang)(yang)處理(li)(li)(li)器(qi)也(ye)能(neng)采用動(dong)態電(dian)壓(ya)調整(zheng)技術(shu);當中央(yang)(yang)處理(li)(li)(li)器(qi)進入待命(ming)模(mo)式或其它功(gong)(gong)能(neng)精簡模(mo)式,它就(jiu)能(neng)在較低的(de)頻(pin)(pin)率頻(pin)(pin)率下工作(zuo),此時可將處理(li)(li)(li)器(qi)電(dian)壓(ya)降低,以便減(jian)少功(gong)(gong)耗,提升工作(zuo)效率,延(yan)長電(dian)池壽命(ming)。

就以OMAP1510為例(li),假設它(ta)的電源是由TPS62200供應,并使用1安培(pei)小時(shi)的3.6V鋰離子電池輸入,其它(ta)特性包括:

●睡眠模式(TPS62200采用(yong)PFM調(diao)變)未用(yong)動態電壓調(diao)整(zheng):Vout=1.5V@300μA;效率=93%

●正常工作模式(TPS62200采用PWM調變):Vout=1.5V@100mA;效(xiao)率=96%

假(jia)設(she)此組件(jian)95%時(shi)間處于睡(shui)(shui)眠模(mo)式,5%時(shi)間處于正常工作模(mo)式,則從輸出(chu)功率與時(shi)間的關系圖可看出(chu),將動態電壓調整技術(shu)用于睡(shui)(shui)眠模(mo)式,電池壽命(ming)會最多延(yan)長9個小(xiao)時(shi)。

離散解決方案

(圖四)是利(li)用離散組件實作的電源管理(li)系統,電池電壓限(xian)制(zhi)為3.3V。

圖四利用離散(san)組件實(shi)作的電源(yuan)管(guan)理系統

在這個解決方(fang)案中,就算鋰離子電(dian)池下降至3.3V左右,在100%負載周期模式下工作(zuo)的(de)(de)高效率TPS62200降壓(ya)轉(zhuan)換(huan)器(qi)(qi)仍能提(ti)供3.3V的(de)(de)I/O電(dian)壓(ya)。上(shang)述所有零件(jian)(jian)(jian)都采(cai)用SOT-23封裝,除了bq24020電(dian)池充電(dian)組件(jian)(jian)(jian)、TPS61020升壓(ya)轉(zhuan)換(huan)器(qi)(qi)以(yi)及TPS61042白(bai)光二極管(guan)驅動組件(jian)(jian)(jian)之外,它們是采(cai)用3×3平方(fang)厘米的(de)(de)QFN封裝。TPS61040和TPS61042還(huan)內建(jian)上(shang)端FET晶(jing)體管(guan),每(mei)顆組件(jian)(jian)(jian)只需(xu)要一個外接二極管(guan)。bq24020、TPS622xx、TPS61020和線性穩壓(ya)器(qi)(qi)組件(jian)(jian)(jian)全都內建(jian)FET晶(jing)體管(guan),功率放(fang)大器(qi)(qi)和中央處理(li)器(qi)(qi)電(dian)源(yuan)采(cai)用的(de)(de)動態電(dian)壓(ya)調整技術可以(yi)提(ti)高每(mei)顆零件(jian)(jian)(jian)的(de)(de)效率,進(jin)而協助降低功耗。

整(zheng)合解決方案

最新制(zhi)程(cheng)技術使得(de)工程(cheng)師更容易結合、迅速(su)修改以(yi)及/或是(shi)利用(yong)現(xian)有的(de)(de)(de)離散組件設(she)計,以(yi)便提(ti)供不同(tong)整(zheng)合程(cheng)度的(de)(de)(de)半(ban)導體(ti)芯片,例如(ru)通用(yong)的(de)(de)(de)雙通道交換(huan)式(shi)轉換(huan)器和電(dian)源拒斥比很高而噪聲很低的(de)(de)(de)雙信道線性穩壓器、特殊應(ying)用(yong)白光二(er)極管(guan)的(de)(de)(de)電(dian)源供應(ying)以(yi)及行動(dong)電(dian)話、PDA和數字相機的(de)(de)(de)多電(dian)源管(guan)理解決方案(an),這些產品都已開始供應(ying)。專門支(zhi)持(chi)終端(duan)設(she)備的(de)(de)(de)電(dian)源組件則(ze)會內(nei)建各種外圍,其范圍從(cong)行動(dong)電(dian)話的(de)(de)(de)響(xiang)鈴器和蜂鳴器到PDA的(de)(de)(de)通用(yong)I/O接腳,例如(ru)圖四整(zheng)合解決方案(an)所使用(yong)的(de)(de)(de)TPS65010就是(shi)這類組件。

圖五整合式解決方案

在此解決方案中,3.3VI/O電源是由SEPIC轉換器提供,它讓應用系統能充份利用鋰離子電池電力,直(zhi)到(dao)(dao)電池電壓降(jiang)至最(zui)(zui)低(di)水(shui)平(ping)(大約2.7V)。和(he)(he)離(li)散解(jie)決方案一樣(yang),穩壓器輸(shu)(shu)(shu)出也來自(zi)3.3V輸(shu)(shu)(shu)入電源(yuan),以(yi)便提高(gao)工作效率(lv)(lv)。TPS65010采用(yong)48只(zhi)接腳QFN封裝(zhuang),這些組件都(dou)內建(jian)FET晶體管。TPS61130SEPIC轉換器采用(yong)4×4平(ping)方厘米(mi)QFN封裝(zhuang),并且內建(jian)FET晶體管,最(zui)(zui)高(gao)達(da)到(dao)(dao)90%以(yi)上(shang)效率(lv)(lv),TPS5100則是三通道輸(shu)(shu)(shu)出控制器,專門用(yong)來提供電源(yuan)給顯示器。功(gong)率(lv)(lv)放大器和(he)(he)中(zhong)央(yang)處理器電源(yuan)使用(yong)的動態(tai)電壓調整技(ji)術可(ke)以(yi)改善(shan)每顆零件的效率(lv)(lv),進而協(xie)助降(jiang)低(di)功(gong)耗。

離散(san)或(huo)整(zheng)合(he)?

如何(he)在離(li)散(san)(san)或(huo)整合解(jie)決方案之(zhi)(zhi)間(jian)做出抉擇(ze)?一般說來,整合組件的(de)(de)成本會低(di)于(yu)(yu)同樣等級的(de)(de)多(duo)顆(ke)離(li)散(san)(san)零件;除此之(zhi)(zhi)外(wai),如同(圖六)的(de)(de)電路(lu)(lu)板布局所示,相較(jiao)于(yu)(yu)執行(xing)同樣功(gong)能的(de)(de)多(duo)顆(ke)離(li)散(san)(san)零件,TPS65010以及(ji)與其搭配的(de)(de)被動(dong)零件只需較(jiao)少(shao)的(de)(de)電路(lu)(lu)板空間(jian),這主要(yao)是(shi)因為離(li)散(san)(san)零件之(zhi)(zhi)間(jian)需要(yao)額(e)外(wai)空間(jian)來容納(na)訊號線路(lu)(lu)。由于(yu)(yu)TPS65010還包含原來由離(li)散(san)(san)零件提供的(de)(de)其它功(gong)能,例如電源供應順(shun)序、振動(dong)器和(he)二極管驅動(dong)組件,因此整合解(jie)決方案可以節省更多(duo)電路(lu)(lu)板面積。

圖六TPS65010與同等級離散解決(jue)方案的電路板布比較

整(zheng)(zheng)合(he)組(zu)件過(guo)去(qu)主要支持特殊應(ying)用,彈性也(ye)不是很高,因此(ci)在設計(ji)(ji)流程(cheng)(cheng)后(hou)期,它們就(jiu)無(wu)法再進行(xing)重(zhong)大的(de)(de)設計(ji)(ji)變更(geng)。然而新的(de)(de)制程(cheng)(cheng)技(ji)術,包括(kuo)支持可程(cheng)(cheng)序(xu)輸出電壓(ya)以及(ji)封(feng)裝(zhuang)后(hou)調整(zheng)(zheng)的(de)(de)整(zheng)(zheng)合(he)式EEPROM,卻使(shi)得工程(cheng)(cheng)師能(neng)以更(geng)低成本,更(geng)簡單快速的(de)(de)對(dui)現有組(zu)件(也(ye)就(jiu)是不同固定輸出電壓(ya)的(de)(de)組(zu)件)重(zhong)復進行(xing)簡單修改。另一(yi)(yi)方(fang)面,整(zheng)(zheng)合(he)組(zu)件的(de)(de)供貨商通常(chang)只有一(yi)(yi)家(jia),這可能(neng)迫使(shi)廠(chang)商必須(xu)采用離散解決方(fang)案。

未(wei)來挑(tiao)戰

消費者(zhe)想要(yao)操作時間更(geng)長的智能型手機,新(xin)發(fa)展的半導體制(zhi)程技術已能減少泄(xie)漏電(dian)流和阻(zu)抗(kang)(有時透過銅覆蓋(gai)層(ceng)),使得FET晶體管(guan)的靜態(tai)電(dian)流更(geng)低,導通阻(zu)抗(kang)也變得更(geng)小。然而不(bu)同(tong)于(yu)持續(xu)進(jin)步中的半導體技術,電(dian)池技術卻沒有任何重大進(jin)展,無法(fa)在不(bu)增加電(dian)池體積(ji)的情(qing)形(xing)下延長供電(dian)時間。

電(dian)(dian)(dian)(dian)(dian)容器(qi)技術(shu)的(de)(de)(de)某(mou)些進展使得充電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)池(chi)和電(dian)(dian)(dian)(dian)(dian)容器(qi)之(zhi)間的(de)(de)(de)界限日益模糊(hu),許多可攜式產品已開始使用高(gao)能(neng)量超級電(dian)(dian)(dian)(dian)(dian)容器(qi)(supercapacitor),做為(wei)消費者更換(huan)電(dian)(dian)(dian)(dian)(dian)池(chi)時的(de)(de)(de)暫時電(dian)(dian)(dian)(dian)(dian)力(li)(li)來源;另外(wai),高(gao)能(neng)量暨高(gao)功率的(de)(de)(de)超高(gao)電(dian)(dian)(dian)(dian)(dian)容器(qi)(ultracapacitor)還能(neng)在短時間內提(ti)供很大電(dian)(dian)(dian)(dian)(dian)流,讓電(dian)(dian)(dian)(dian)(dian)池(chi)不(bu)必(bi)瞬間供應龐大電(dian)(dian)(dian)(dian)(dian)力(li)(li),可以延(yan)長電(dian)(dian)(dian)(dian)(dian)池(chi)的(de)(de)(de)使用時間。這些超高(gao)電(dian)(dian)(dian)(dian)(dian)容器(qi)會(hui)整(zheng)合至(zhi)電(dian)(dian)(dian)(dian)(dian)池(chi)封裝內,并在系(xi)統電(dian)(dian)(dian)(dian)(dian)力(li)(li)需求不(bu)太高(gao)時,利用微小電(dian)(dian)(dian)(dian)(dian)流充電(dian)(dian)(dian)(dian)(dian)。

燃料電(dian)池(chi)(chi)近來是(shi)熱門話題,但由于外形包裝(zhuang)尚未標準化(hua),使(shi)得燃料電(dian)池(chi)(chi)的廣泛應(ying)用受到影響,商業化(hua)過程也不太順利。燃料電(dian)池(chi)(chi)的輸(shu)出瞬時(shi)響應(ying)也很糟糕,因此(ci)至(zhi)少在最初階段(duan)燃料電(dian)池(chi)(chi)只會做為普(pu)通(tong)(tong)電(dian)池(chi)(chi)的補(bu)強裝(zhuang)置,無法取代普(pu)通(tong)(tong)電(dian)池(chi)(chi)。

消費者還希望產品的(de)體(ti)(ti)積(ji)(ji)更(geng)(geng)小,功能更(geng)(geng)加強大,創新的(de)電源管理組件設計以(yi)(yi)及封裝和制程(cheng)技術的(de)進(jin)步都能幫助實(shi)現此目標。日益精密的(de)制程(cheng)技術可以(yi)(yi)制造出越來越小的(de)FET晶(jing)體(ti)(ti)管,讓晶(jing)粒和封裝的(de)體(ti)(ti)積(ji)(ji)更(geng)(geng)小,工作(zuo)電壓更(geng)(geng)低(di),閘(zha)極電容更(geng)(geng)少(shao),使得晶(jing)體(ti)(ti)管的(de)開關速度更(geng)(geng)快

―對于以電(dian)感為基礎的(de)(de)(de)交換式電(dian)源供應,更(geng)快的(de)(de)(de)開(kai)關(guan)速度(du)意味(wei)著(zhu)更(geng)小的(de)(de)(de)電(dian)感。新(xin)封(feng)裝技術則能(neng)在更(geng)小的(de)(de)(de)封(feng)裝中容納(na)更(geng)多功能(neng),并且(qie)承受更(geng)大的(de)(de)(de)功耗(hao),例(li)如(ru)內建FET開(kai)關(guan)的(de)(de)(de)鋰離子電(dian)池線性充電(dian)組(zu)件bq24010就(jiu)采用3×3平方厘米的(de)(de)(de)QFN封(feng)裝,它在普通室溫(wen)環境下,最高能(neng)承受1.5W功耗(hao)。

要在較低(di)的(de)(de)(de)工作電(dian)壓(ya)下提供更(geng)強大(da)功(gong)能,電(dian)源管(guan)理單元和低(di)噪聲布局(ju)的(de)(de)(de)容忍(ren)要求通常也會(hui)變的(de)(de)(de)更(geng)嚴格,例如系(xi)統若要求1.2V電(dian)源的(de)(de)(de)誤(wu)差小(xiao)(xiao)于±3%,就表示(shi)輸出電(dian)壓(ya)變動幅度不能超過±36mV;相形(xing)之下,使(shi)用3.3V電(dian)源就表示(shi)在同樣的(de)(de)(de)±3%誤(wu)差限制(zhi)下,它(ta)能容忍(ren)的(de)(de)(de)電(dian)壓(ya)變動高達±99mV。由于電(dian)源電(dian)壓(ya)不斷降(jiang)低(di),未來幾年內(nei)對于誤(wu)差更(geng)小(xiao)(xiao)、電(dian)流(liu)更(geng)大(da)、效率更(geng)高和電(dian)磁干擾極低(di)的(de)(de)(de)直流(liu)電(dian)源轉(zhuan)換(huan)器的(de)(de)(de)需(xu)求將會(hui)增加(jia)。除(chu)此之外(wai),隨著(zhu)封(feng)裝縮小(xiao)(xiao),可供散熱的(de)(de)(de)面積(ji)也會(hui)減少(shao),讓這些(xie)高功(gong)耗(hao)組件(jian)的(de)(de)(de)熱管(guan)理繼續成為困難(nan)挑戰(zhan)。

整(zheng)合的(de)力量

本文介紹的(de)電(dian)源解決方案使用(yong)不同整合(he)程度的(de)電(dian)源組(zu)件(jian)。把部(bu)(bu)份(fen)或(huo)全部(bu)(bu)的(de)模擬電(dian)源組(zu)件(jian)和基(ji)頻(pin)處理(li)器等數字(zi)零(ling)件(jian)整合(he)在一起會(hui)帶來許多優點(dian),包括(kuo)節省更(geng)多的(de)電(dian)路(lu)板面積,并且降低總成本。復雜電(dian)子系(xi)統的(de)每個部(bu)(bu)份(fen)都有著不同的(de)需求,這是過去實現(xian)更(geng)高(gao)階數字(zi)和模擬零(ling)件(jian)整合(he)的(de)障(zhang)礙(ai)之一,例如數字(zi)基(ji)頻(pin)單元(yuan)需要(yao)(yao)高(gao)密(mi)度制程以支(zhi)持(chi)數字(zi)訊號處理(li),模擬基(ji)頻(pin)和電(dian)源功能(neng)需要(yao)(yao)電(dian)壓更(geng)高(gao)的(de)組(zu)件(jian);射(she)頻(pin)單元(yuan),特別是鎖相回(hui)路(lu),則需要(yao)(yao)最適合(he)支(zhi)持(chi)高(gao)頻(pin)操作的(de)BiCMOS組(zu)件(jian)。

傳統上,制程(cheng)(cheng)發展(zhan)(zhan)是(shi)由數(shu)字設(she)計(ji)人(ren)員負責管理(li),他們(men)通常(chang)只會推動高(gao)密度(du)(du)制程(cheng)(cheng)發展(zhan)(zhan),電(dian)(dian)路若需要(yao)高(gao)電(dian)(dian)壓組(zu)(zu)件,就(jiu)必須采用不同(tong)制程(cheng)(cheng),這表示他們(men)需要(yao)獨立的(de)數(shu)字組(zu)(zu)件。半導(dao)體廠商不但(dan)開始(shi)發展(zhan)(zhan)「最小閘極長(chang)度(du)(du)」更短(duan)的(de)BiCMOS制程(cheng)(cheng),以(yi)便提(ti)供(gong)很高(gao)的(de)組(zu)(zu)件密度(du)(du)和工作速度(du)(du),還有更高(gao)電(dian)(dian)壓的(de)汲極延伸型組(zu)(zu)件(drainextendeddevices),它們(men)已(yi)用于更多的(de)模擬和電(dian)(dian)源應用。包括電(dian)(dian)源管理(li)在(zai)內的(de)許多模擬和數(shu)字功能最后都會整(zheng)合成單(dan)顆芯(xin)片。

不同程(cheng)度的組(zu)件(jian)(jian)整(zheng)合正在簡化可(ke)攜(xie)式(shi)電(dian)(dian)源(yuan)(yuan)設(she)計(ji),尤(you)其是可(ke)攜(xie)式(shi)產品的系統設(she)計(ji)人員,他們不必再擔(dan)心組(zu)件(jian)(jian)的電(dian)(dian)源(yuan)(yuan)需求(qiu)管理(li)(li),整(zheng)合程(cheng)度不同的電(dian)(dian)源(yuan)(yuan)管理(li)(li)組(zu)件(jian)(jian)可(ke)以幫(bang)助他們讓電(dian)(dian)池提供最長供電(dian)(dian)時(shi)間,同時(shi)將(jiang)電(dian)(dian)路(lu)板面(mian)積和成(cheng)本(ben)減(jian)至(zhi)最少。