電源PCB布線原則及走線技巧

文章主要是(shi)討論和分析開(kai)關(guan)(guan)電源印(yin)制(zhi)板(ban)(ban)布線原則(ze)、開(kai)關(guan)(guan)電源印(yin)制(zhi)板(ban)(ban)銅皮走線的(de)一(yi)些事(shi)項、開(kai)關(guan)(guan)電源印(yin)制(zhi)板(ban)(ban)大電流走線的(de)處理以及反激電源反射電壓的(de)一(yi)個(ge)確定因(yin)素等方面,解(jie)決鋁(lv)基板(ban)(ban)在開(kai)關(guan)(guan)電源中的(de)應用、多層印(yin)制(zhi)板(ban)(ban)在開(kai)關(guan)(guan)電源電路中的(de)應用的(de)一(yi)些大家關(guan)(guan)注(zhu)的(de)問題。

一、引言

開(kai)(kai)(kai)關(guan)電(dian)(dian)(dian)源(yuan)(yuan)是(shi)一種(zhong)(zhong)電(dian)(dian)(dian)壓(ya)轉(zhuan)換電(dian)(dian)(dian)路(lu),主(zhu)要(yao)的(de)工作內容是(shi)升壓(ya)和(he)(he)降壓(ya),廣泛應(ying)用于現代電(dian)(dian)(dian)子產(chan)品。因為開(kai)(kai)(kai)關(guan)三(san)極(ji)管總是(shi)工作在(zai) “開(kai)(kai)(kai)” 和(he)(he)“關(guan)” 的(de)狀態,所以叫(jiao)開(kai)(kai)(kai)關(guan)電(dian)(dian)(dian)源(yuan)(yuan)。開(kai)(kai)(kai)關(guan)電(dian)(dian)(dian)源(yuan)(yuan)實質就是(shi)一個振蕩電(dian)(dian)(dian)路(lu),這(zhe)種(zhong)(zhong)轉(zhuan)換電(dian)(dian)(dian)能(neng)的(de)方式(shi),不(bu)僅應(ying)用在(zai)電(dian)(dian)(dian)源(yuan)(yuan)電(dian)(dian)(dian)路(lu),在(zai)其它(ta)的(de)電(dian)(dian)(dian)路(lu)應(ying)用也很普遍,如液(ye)晶顯示器(qi)的(de)背(bei)光電(dian)(dian)(dian)路(lu)、日光燈(deng)等。開(kai)(kai)(kai)關(guan)電(dian)(dian)(dian)源(yuan)(yuan)與(yu)變壓(ya)器(qi)相比具有(you)效率(lv)高、穩性(xing)好、體(ti)積小等優點(dian),缺點(dian)是(shi)功率(lv)相對(dui)較小,而(er)且會對(dui)電(dian)(dian)(dian)路(lu)產(chan)生(sheng)高頻(pin)干擾(rao),變壓(ya)器(qi)反饋(kui)式(shi)振蕩電(dian)(dian)(dian)路(lu),能(neng)產(chan)生(sheng)有(you)規律的(de)脈沖電(dian)(dian)(dian)流或(huo)電(dian)(dian)(dian)壓(ya)的(de)電(dian)(dian)(dian)路(lu)叫(jiao)振蕩電(dian)(dian)(dian)路(lu),變壓(ya)器(qi)反饋(kui)式(shi)振蕩電(dian)(dian)(dian)路(lu)就是(shi)能(neng)滿(man)足這(zhe)種(zhong)(zhong)條(tiao)件的(de)電(dian)(dian)(dian)路(lu)。

開(kai)關電(dian)(dian)源(yuan)(yuan)分為(wei),隔(ge)(ge)離與非隔(ge)(ge)離兩種形(xing)式,在(zai)這里主要談一談隔(ge)(ge)離式開(kai)關電(dian)(dian)源(yuan)(yuan)的拓撲形(xing)式,在(zai)下(xia)文中(zhong),非特別說明(ming),均(jun)指(zhi)隔(ge)(ge)離電(dian)(dian)源(yuan)(yuan)。隔(ge)(ge)離電(dian)(dian)源(yuan)(yuan)按(an)照結構(gou)形(xing)式不同(tong)(tong),可分為(wei)兩大類:正(zheng)激(ji)(ji)式和反(fan)激(ji)(ji)式。反(fan)激(ji)(ji)式指(zhi)在(zai)變壓器原邊(bian)(bian)導通時(shi)(shi)副邊(bian)(bian)截止(zhi),變壓器儲(chu)能。原邊(bian)(bian)截止(zhi)時(shi)(shi),副邊(bian)(bian)導通,能量釋放(fang)到負(fu)載的工作狀態,一般常(chang)(chang)規反(fan)激(ji)(ji)式電(dian)(dian)源(yuan)(yuan)單(dan)(dan)管(guan)多,雙管(guan)的不常(chang)(chang)見(jian)。正(zheng)激(ji)(ji)式指(zhi)在(zai)變壓器原邊(bian)(bian)導通同(tong)(tong)時(shi)(shi)副邊(bian)(bian)感(gan)應(ying)出對應(ying)電(dian)(dian)壓輸出到負(fu)載,能量通過變壓器直接傳遞(di)。按(an)規格(ge)又可分為(wei)常(chang)(chang)規正(zheng)激(ji)(ji),包括(kuo)單(dan)(dan)管(guan)正(zheng)激(ji)(ji),雙管(guan)正(zheng) 激(ji)(ji)。半橋、橋式電(dian)(dian)路都(dou)屬于正(zheng)激(ji)(ji)電(dian)(dian)路。

正(zheng)激(ji)(ji)和反激(ji)(ji)電路(lu)(lu)各有其特點(dian),在設(she)計電路(lu)(lu)的過程中為達到最優性價比,可(ke)(ke)(ke)以(yi)靈(ling)活運用(yong)。一(yi)般(ban)在小功(gong)率場合可(ke)(ke)(ke)選(xuan)用(yong)反激(ji)(ji)式。稍(shao)微(wei)大一(yi)些(xie)可(ke)(ke)(ke)采(cai)(cai)用(yong)單管正(zheng)激(ji)(ji)電路(lu)(lu),中等功(gong)率可(ke)(ke)(ke)采(cai)(cai)用(yong)雙管正(zheng)激(ji)(ji)電路(lu)(lu)或半橋電路(lu)(lu),低電壓時采(cai)(cai)用(yong)推(tui)(tui)挽(wan)電路(lu)(lu),與半橋工作狀態(tai)相(xiang)同。大功(gong)率輸出,一(yi)般(ban)采(cai)(cai)用(yong)橋式電路(lu)(lu),低壓也可(ke)(ke)(ke)采(cai)(cai)用(yong)推(tui)(tui)挽(wan)電路(lu)(lu)。

反(fan)激式電(dian)(dian)源(yuan)(yuan)因(yin)其結(jie)構簡(jian)單,省掉了一個和(he)變壓器體積大小差(cha)不(bu)多的(de)電(dian)(dian)感,而(er)在(zai)中(zhong)(zhong)小功率電(dian)(dian)源(yuan)(yuan)中(zhong)(zhong)得到(dao)(dao)(dao)(dao)廣泛的(de)應用。在(zai)有(you)些(xie)介(jie)紹中(zhong)(zhong)講到(dao)(dao)(dao)(dao)反(fan)激式電(dian)(dian)源(yuan)(yuan)功率只能做到(dao)(dao)(dao)(dao)幾十瓦(wa),輸出功率超過100瓦(wa)就(jiu)沒有(you)優勢,實(shi)現起來(lai)有(you)難度。本人認為一般情況下是這樣的(de),但也不(bu)能一概而(er)論,PI公司的(de)TOP芯片(pian)就(jiu)可做到(dao)(dao)(dao)(dao)300瓦(wa),有(you)文章(zhang)介(jie)紹反(fan)激電(dian)(dian)源(yuan)(yuan)可做到(dao)(dao)(dao)(dao)上千瓦(wa),但沒見過實(shi)物。輸出功率大小與輸出電(dian)(dian)壓高低有(you)關。

反激電源(yuan)變壓(ya)(ya)器漏感是一個非(fei)常關鍵(jian)的(de)參數,由于(yu)反激電源(yuan)需要(yao)變壓(ya)(ya)器儲存能(neng)量,要(yao) 使(shi)(shi)變壓(ya)(ya)器鐵(tie)芯(xin)得到充分利用,一般都要(yao)在磁路中開氣(qi)隙(xi),其目的(de)是改變鐵(tie)芯(xin)磁滯(zhi)回線(xian)的(de)斜率,使(shi)(shi)變壓(ya)(ya)器能(neng)夠(gou)承(cheng)受大(da)的(de)脈沖電流沖擊,而(er)不至(zhi)于(yu)鐵(tie)芯(xin)進入飽(bao)和非(fei)線(xian)形(xing)狀 態,磁路中氣(qi)隙(xi)處于(yu)高(gao)磁阻狀態,在磁路中產生漏磁遠大(da)于(yu)完全閉合磁路。

脈沖(chong)電(dian)壓連(lian)線(xian)盡可(ke)(ke)能(neng)短,其中(zhong)輸(shu)(shu)(shu)入(ru)(ru)開關(guan)(guan)(guan)管到變(bian)(bian)壓器(qi)(qi)(qi)(qi)連(lian)線(xian),輸(shu)(shu)(shu)出(chu)變(bian)(bian)壓器(qi)(qi)(qi)(qi)到整流管連(lian)接線(xian)。脈沖(chong)電(dian)流環路(lu)(lu)盡可(ke)(ke)能(neng)小(xiao)如輸(shu)(shu)(shu)入(ru)(ru)濾波(bo)電(dian)容(rong)(rong)正到變(bian)(bian)壓器(qi)(qi)(qi)(qi)到開關(guan)(guan)(guan)管返回(hui)電(dian)容(rong)(rong)負。輸(shu)(shu)(shu)出(chu)部分變(bian)(bian)壓器(qi)(qi)(qi)(qi)出(chu)端到整流管到輸(shu)(shu)(shu)出(chu)電(dian)感(gan)到輸(shu)(shu)(shu)出(chu)電(dian)容(rong)(rong)返回(hui)變(bian)(bian)壓器(qi)(qi)(qi)(qi)電(dian)路(lu)(lu)中(zhong)X電(dian)容(rong)(rong)要盡量接 近開關(guan)(guan)(guan)電(dian)源輸(shu)(shu)(shu)入(ru)(ru)端,輸(shu)(shu)(shu)入(ru)(ru)線(xian)應(ying)避免與(yu)其他電(dian)路(lu)(lu)平行,應(ying)避開。Y電(dian)容(rong)(rong)應(ying)放置在(zai)機(ji)殼接地端子或FG連(lian)接端。共(gong)摸電(dian)感(gan)應(ying)與(yu)變(bian)(bian)壓器(qi)(qi)(qi)(qi)保持(chi)一定(ding)距離,以避免磁偶(ou)合。

輸出(chu)電(dian)(dian)(dian)容(rong)一(yi)(yi)般可(ke)采用兩只一(yi)(yi)只靠近整(zheng)流(liu)管(guan)另一(yi)(yi)只應靠近輸出(chu)端(duan)子,可(ke)影響(xiang)電(dian)(dian)(dian)源輸出(chu)紋波(bo)指(zhi)標,兩只小容(rong)量電(dian)(dian)(dian)容(rong)并(bing)聯(lian)效果應優于用一(yi)(yi)只大容(rong)量電(dian)(dian)(dian)容(rong)。發熱(re)器(qi)件要(yao)和(he)電(dian)(dian)(dian)解 電(dian)(dian)(dian)容(rong)保(bao)持(chi)一(yi)(yi)定距離,以(yi)延(yan)長整(zheng)機(ji)壽(shou)命(ming),電(dian)(dian)(dian)解電(dian)(dian)(dian)容(rong)是開關電(dian)(dian)(dian)源壽(shou)命(ming)的瓶勁(jing),如變壓器(qi)、功率管(guan)、大功率電(dian)(dian)(dian)阻要(yao)和(he)電(dian)(dian)(dian)解保(bao)持(chi)距離,電(dian)(dian)(dian)解之間(jian)也須留出(chu)散熱(re)空間(jian),條件允許(xu)可(ke)將其(qi)放置在進風口(kou)。

二、印制板布線的一些原則

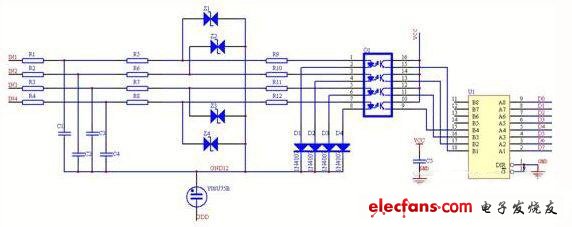

印(yin)(yin)制板(ban)設計(ji)(ji)時,要(yao)考慮到(dao)干(gan)擾對(dui)(dui)系(xi)統(tong)的(de)影響(xiang),將(jiang)(jiang)電(dian)(dian)(dian)路(lu)(lu)的(de)模擬部(bu)分和數字部(bu)分的(de)電(dian)(dian)(dian)路(lu)(lu)嚴(yan)格分開,對(dui)(dui)核心(xin)電(dian)(dian)(dian)路(lu)(lu)重點防護,將(jiang)(jiang)系(xi)統(tong)地線(xian)環繞(rao),并布(bu)線(xian)盡可能(neng)粗,電(dian)(dian)(dian)源(yuan)增加(jia)濾(lv)波電(dian)(dian)(dian)路(lu)(lu),采(cai)用DC-DC隔(ge)離,信(xin)號采(cai)用光電(dian)(dian)(dian)隔(ge)離,設計(ji)(ji)隔(ge)離電(dian)(dian)(dian)源(yuan),分析容(rong)(rong)易產生干(gan)擾的(de)部(bu)分(如時鐘電(dian)(dian)(dian)路(lu)(lu)、通訊(xun)電(dian)(dian)(dian)路(lu)(lu)等)和容(rong)(rong)易被干(gan)擾的(de)部(bu)分(如模擬采(cai)樣電(dian)(dian)(dian)路(lu)(lu)等),對(dui)(dui)這(zhe)兩種類型的(de)電(dian)(dian)(dian)路(lu)(lu)分別采(cai)取(qu)措施。對(dui)(dui)于干(gan)擾元件采(cai)取(qu)抑制措施,對(dui)(dui)敏感(gan)元件采(cai)取(qu)隔(ge)離和保護措施,并且(qie)將(jiang)(jiang)它們在(zai)空(kong)間和電(dian)(dian)(dian)氣上拉開距(ju)離。在(zai)板(ban)級設計(ji)(ji)時,還要(yao)注意元器件放置要(yao)遠離印(yin)(yin)制板(ban)邊沿(yan),這(zhe)對(dui)(dui)防護空(kong)氣放電(dian)(dian)(dian)是有利的(de)。樣電(dian)(dian)(dian)路(lu)(lu)的(de)原(yuan)理圖設計(ji)(ji)參見圖1。

圖1 樣電路的(de)原(yuan)理(li)圖設計(ji)原(yuan)理(li)圖

線(xian)(xian)間(jian)(jian)距(ju)(ju):隨著印(yin)制(zhi)線(xian)(xian)路板制(zhi)造(zao)工(gong)藝(yi)(yi)的不(bu)斷完(wan)善和提高(gao),一(yi)般加工(gong)廠(chang)制(zhi)造(zao)出(chu)線(xian)(xian)間(jian)(jian)距(ju)(ju)等于(yu)甚至(zhi)小(xiao)于(yu)0.1mm已經(jing)不(bu)存(cun)在(zai)什么問(wen)題,完(wan)全能(neng)夠滿(man)足大(da)多(duo)數應用場合(he)。考慮 到開關電源所采用的元(yuan)器件及(ji)生(sheng)產(chan)工(gong)藝(yi)(yi),一(yi)般雙(shuang)面板最小(xiao)線(xian)(xian)間(jian)(jian)距(ju)(ju)設為0.3mm,單面板最小(xiao)線(xian)(xian)間(jian)(jian)距(ju)(ju)設為0.5mm,焊(han)盤(pan)與焊(han)盤(pan)、焊(han)盤(pan)與過(guo)孔(kong)或過(guo)孔(kong)與過(guo)孔(kong),最小(xiao) 間(jian)(jian)距(ju)(ju)設為0.5mm,可避免在(zai)焊(han)接(jie)操作過(guo)程中出(chu)現(xian)“橋接(jie)”現(xian)象。,這(zhe)樣(yang)大(da)多(duo)數制(zhi)板廠(chang)都能(neng)夠很輕松滿(man)足生(sheng)產(chan)要求(qiu),并可以把成品率控(kong)制(zhi)得非(fei)常高(gao),亦可實現(xian)合(he)理(li) 的布線(xian)(xian)密度及(ji)有一(yi)個(ge)較經(jing)濟的成本。