開關型鉛酸蓄電池智能充電器

設計了一種基于UC3906與UC3823的免維護鉛酸蓄電池開關型雙電平智能充電器, 這種充電器可保證蓄電池在很寬的溫(wen)度范圍(wei)內(nei)精(jing)確(que)充電, 延長蓄電池(chi)的使用壽命; 可以消(xiao)除充電過程中的極化現象, 提高充電效率(lv)。

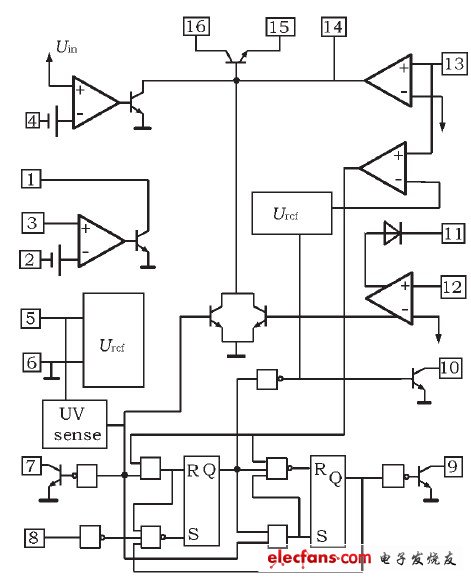

1 UC3906的(de)結(jie)構(gou)及(ji)工作原(yuan)理。

UC3906內部框圖如圖1所示,該芯片內含有獨立的電壓控制電路和限流放大器, 它可以控制芯片內的驅動器, 驅動器提供的輸出電流達25 mA, 可直接驅動外部串聯的調整管, 從而調整充電器的輸(shu)出電(dian)壓與(yu)電(dian)流。電(dian)壓和(he)電(dian)流檢測比較器檢測蓄電(dian)池的充(chong)電(dian)狀態, 并控制狀態邏輯電(dian)路的輸(shu)入信號。

圖1 UC3906內部結構框圖

當蓄電池電壓或電流過低時, 充電起動比較器控制充電器進入涓流充電狀態, 當驅動器截止時,該比較器還能輸出25 mA涓流充電電流。這樣, 當蓄電池短路或反接時, 充電器只能以小電流充電,避免了因充電(dian)電(dian)流過大而損壞蓄(xu)電(dian)池。

蓄(xu)(xu)電(dian)(dian)(dian)池(chi)的(de)(de)(de)電(dian)(dian)(dian)壓與環境(jing)溫(wen)(wen)度(du)(du)有(you)(you)關, 溫(wen)(wen)度(du)(du)每升高1 ℃, 蓄(xu)(xu)電(dian)(dian)(dian)池(chi)單格(ge)電(dian)(dian)(dian)壓下降(jiang)4 mV, 也(ye)就是(shi)說(shuo)蓄(xu)(xu)電(dian)(dian)(dian)池(chi)的(de)(de)(de)浮充(chong)(chong)電(dian)(dian)(dian)壓有(you)(you)負的(de)(de)(de)溫(wen)(wen)度(du)(du)系數- 4 mV/℃。普通(tong)充(chong)(chong)電(dian)(dian)(dian)器如果在(zai)25 ℃處于最佳(jia)工作狀態, 在(zai)環境(jing)溫(wen)(wen)度(du)(du)為(wei)0 ℃就會充(chong)(chong)電(dian)(dian)(dian)不足(zu), 而在(zai)溫(wen)(wen)度(du)(du)為(wei)45 ℃時可能因嚴重(zhong)(zhong)過充(chong)(chong)電(dian)(dian)(dian)而縮短蓄(xu)(xu)電(dian)(dian)(dian)池(chi)的(de)(de)(de)使用壽命。而UC3906的(de)(de)(de)最重(zhong)(zhong)要(yao)的(de)(de)(de)特(te)性是(shi)具有(you)(you)精確(que)的(de)(de)(de)基準電(dian)(dian)(dian)壓, 其基準電(dian)(dian)(dian)壓的(de)(de)(de)大(da)小隨環境(jing)溫(wen)(wen)度(du)(du)而變化, 且變化規律與鉛酸蓄(xu)(xu)電(dian)(dian)(dian)池(chi)的(de)(de)(de)溫(wen)(wen)度(du)(du)特(te)性一致。同時芯片只(zhi)需(xu)(xu)1.7 mA的(de)(de)(de)輸入電(dian)(dian)(dian)流就可工作, 這樣可以(yi)盡量減(jian)小芯片的(de)(de)(de)功耗, 實現對(dui)環境(jing)溫(wen)(wen)度(du)(du)的(de)(de)(de)準確(que)檢測(ce)。在(zai)0~70 ℃溫(wen)(wen)度(du)(du)范圍內(nei)可以(yi)保證蓄(xu)(xu)電(dian)(dian)(dian)池(chi)既充(chong)(chong)足(zu)電(dian)(dian)(dian)又不會出現過充(chong)(chong)電(dian)(dian)(dian)現象(xiang), 完全滿足(zu)蓄(xu)(xu)電(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)需(xu)(xu)要(yao)。

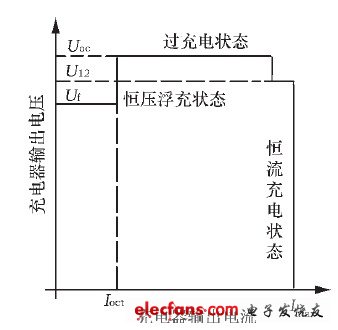

UC3906可構成雙電平浮充充電器, 充電(dian)過(guo)程分為3個充電(dian)狀(zhuang)態(tai), 如圖(tu)2所示: 大(da)電(dian)流恒流充電(dian)狀(zhuang)態(tai), 高電(dian)壓(ya)過(guo)充電(dian)狀(zhuang)態(tai)和低電(dian)壓(ya)恒壓(ya)浮充狀(zhuang)態(tai)。

圖(tu)2 雙(shuang)電平浮充(chong)充(chong)電狀態曲(qu)線

充電過程從大電流恒流充電狀態開始, 在這種狀態下充電器輸出恒定的充電電流Imax, 同時充電器連續監控蓄電池組的兩端電壓, 當蓄電池的電壓達到轉換電壓U12時, 其電量已恢復到放電容量的70%~90%, 充電器轉入過充電狀態。在此狀態下, 充電器輸出電壓升高到Uoc; 由于充電器輸出電壓保持恒定不變, 所以充電電流連續下降, 當電流下降到Ioct時, 蓄電池的容量已達到額定容量的100% ,充電器輸出電壓(ya)下降到(dao)較低的浮充(chong)電壓(ya)UF.

2 電路設計。

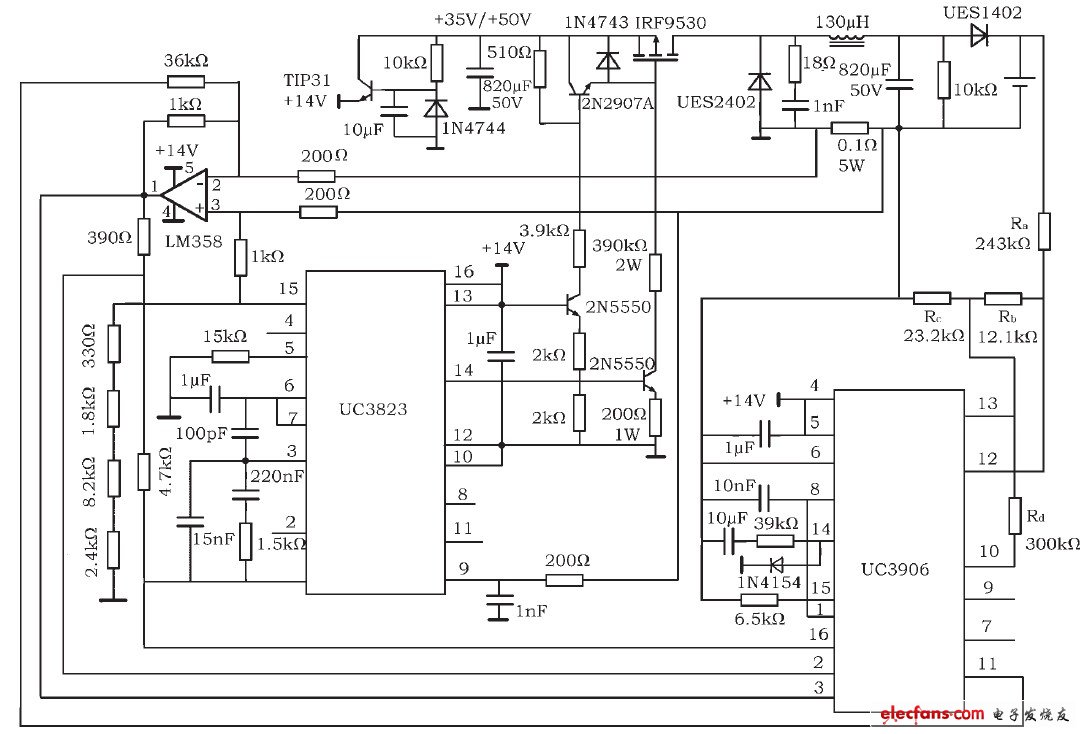

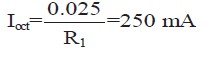

對于較大容量的鉛酸蓄電池, 為了提高充電效率, 通常選用開關型充電器。設計的24V20Ah鉛酸蓄電池開關型充電器實際電路見圖3, 在該電路中,用兩只專用集成電路UC3906與UC3823和一只通用運放即可完成全部控制功能。充電器主(zhu)電路由功(gong)率MOSFET ( IRF9503) 、續流二極管(guan)( UES2402) 和濾波電感( 130 μH) 等元(yuan)件組(zu)成。

圖3 24 V 20 Ah鉛酸蓄電池開關型雙電平浮充智能充電器電路圖

2.1 電(dian)(dian)壓電(dian)(dian)流控(kong)制(zhi)回路與(yu)電(dian)(dian)池充電(dian)(dian)邏輯狀態電(dian)(dian)路

對小容量蓄(xu)(xu)電(dian)(dian)(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)器可采用線性串聯(lian)調整管(guan)來控(kong)制充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)流, 而對于開關型充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)器, UC3906鉛(qian)酸(suan)蓄(xu)(xu)電(dian)(dian)(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)控(kong)制集成電(dian)(dian)(dian)(dian)(dian)路具有充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)壓控(kong)制和充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)邏輯狀(zhuang)態控(kong)制的(de)功(gong)能(neng), 并能(neng)提(ti)供充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)的(de)溫度(du)補償控(kong)制功(gong)能(neng)。

蓄電(dian)池兩端的(de)分(fen)壓(ya)(ya)(ya)(ya)電(dian)阻(zu)監控(kong)蓄電(dian)池電(dian)壓(ya)(ya)(ya)(ya), 分(fen)壓(ya)(ya)(ya)(ya)電(dian)阻(zu)的(de)阻(zu)值確定浮充(chong)電(dian)壓(ya)(ya)(ya)(ya)、過充(chong)電(dian)壓(ya)(ya)(ya)(ya)和(he)涓流充(chong)電(dian)門(men)限電(dian)壓(ya)(ya)(ya)(ya)。差動電(dian)流取(qu)樣比較器產(chan)生(sheng)過充(chong)電(dian)狀態的(de)轉換信(xin)號, 電(dian)壓(ya)(ya)(ya)(ya)放大器放大補(bu)償電(dian)壓(ya)(ya)(ya)(ya)回路的(de)信(xin)號。

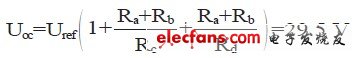

在溫度(du)為25 ℃, Uref值為2.3 V時:

過充電壓:

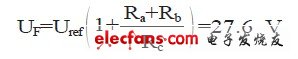

浮充電壓:

過充轉換(huan)電壓(ya):U12=0.95Uoc=28.03 V

浮充轉換電壓:U13=0.9UF=24.8 V

最大充電電流:

過充終止電流:

2.2 開關(guan)型電流源控制回(hui)路(lu)

輸入(ru)電(dian)(dian)(dian)壓( 35 /50 V) 經10 kΩ電(dian)(dian)(dian)阻(zu)與1N4744穩壓管組成的(de)穩壓電(dian)(dian)(dian)路穩壓后, 又(you)經TIP31晶體管射隨器輸出+14 V電(dian)(dian)(dian)壓, 作為控制(zhi)電(dian)(dian)(dian)路的(de)電(dian)(dian)(dian)源電(dian)(dian)(dian)壓。

PWM頻率設定為(wei)100 kHz, 以減小輸出濾波器的體積, 蓄(xu)電池(chi)充電電流從0.1 Ω/5 W電阻(zu)上取樣(yang), 差動放大增益為(wei)5。

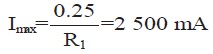

開關型電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)源(yuan)控(kong)制(zhi)回路(lu)(lu)的(de)(de)(de)性能對(dui)充(chong)(chong)電(dian)(dian)狀態(tai)(tai)控(kong)制(zhi)轉換有(you)很(hen)(hen)大的(de)(de)(de)影響(xiang), 在(zai)大電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)快(kuai)速充(chong)(chong)電(dian)(dian)狀態(tai)(tai)下(xia), 充(chong)(chong)電(dian)(dian)器要(yao)(yao)能提(ti)供最大的(de)(de)(de)充(chong)(chong)電(dian)(dian)電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu); 在(zai)浮(fu)充(chong)(chong)狀態(tai)(tai)下(xia), 充(chong)(chong)電(dian)(dian)器輸出電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)很(hen)(hen)小(xiao)。因此(ci), 充(chong)(chong)電(dian)(dian)器電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)控(kong)制(zhi)回路(lu)(lu)的(de)(de)(de)增益(yi)變化(hua)范圍應大于60 db, 采用(yong)普通(tong)的(de)(de)(de)峰值電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)反(fan)饋很(hen)(hen)難滿足要(yao)(yao)求, 24 V20 Ah鉛(qian)酸蓄(xu)電(dian)(dian)池開關型充(chong)(chong)電(dian)(dian)器采用(yong)平均電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)反(fan)饋回路(lu)(lu)見圖4.它比峰值電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)反(fan)饋控(kong)制(zhi)相對(dui)復雜, 利用(yong)平均電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)反(fan)饋控(kong)制(zhi)回路(lu)(lu)可(ke)(ke)以使充(chong)(chong)電(dian)(dian)器電(dian)(dian)路(lu)(lu)在(zai)以下(xia)幾方(fang)面(mian)有(you)所改進: ①由于誤差放大在(zai)較低工作(zuo)頻率范圍內的(de)(de)(de)高(gao)增益(yi), 從(cong)而使閉環電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)的(de)(de)(de)控(kong)制(zhi)精(jing)度得到(dao)了(le)提(ti)高(gao); ②在(zai)大電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)充(chong)(chong)電(dian)(dian)的(de)(de)(de)工作(zuo)狀態(tai)(tai)下(xia), 當電(dian)(dian)感(gan)電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)不連續時, 可(ke)(ke)以改善(shan)大電(dian)(dian)流(liu)(liu)(liu)(liu)(liu)(liu)輸出級的(de)(de)(de)非線性; ③可(ke)(ke)以提(ti)高(gao)充(chong)(chong)電(dian)(dian)器電(dian)(dian)路(lu)(lu)在(zai)很(hen)(hen)小(xiao)的(de)(de)(de)脈沖占空比工作(zuo)條件下(xia)的(de)(de)(de)抗開關峰值噪聲的(de)(de)(de)能力。

圖4 平均電(dian)流反饋電(dian)路圖

電流(liu)控制回路選用UC3823PWM控制器(qi), 因為(wei)它在非常小(xiao)的(de)脈沖(chong)占空比(bi)(bi)到100%的(de)脈沖(chong)占空比(bi)(bi)的(de)變化范圍內能(neng)夠線性工作; UC3823PWM控制器(qi)的(de)帶寬和(he)電路結構完全(quan)滿(man)足平均電流(liu)控制回路的(de)要(yao)求(qiu); UC3823PWM控制器(qi)輸出(chu)驅(qu)動級(ji)與開關(guan)電流(liu)源輸出(chu)功率級(ji)連接(jie)簡單。運放當作差動放大器(qi)使用,用以檢(jian)測開關(guan)電流(liu)源的(de)輸出(chu)電流(liu), 并把該電流(liu)信號變換(huan)為(wei)適當的(de)電壓信號。

2.3 功率輸出(chu)級

功率輸出級(ji)采用(yong)(yong)降壓(ya)式開關電(dian)(dian)(dian)(dian)(dian)(dian)流(liu)源(yuan)。為(wei)了簡(jian)化UC3823的(de)高端驅動電(dian)(dian)(dian)(dian)(dian)(dian)路, 輸出開關管(guan)采用(yong)(yong)直接耦(ou)合P溝道MOSFET.流(liu)入MOSFET的(de)開關電(dian)(dian)(dian)(dian)(dian)(dian)流(liu)提供柵(zha)極電(dian)(dian)(dian)(dian)(dian)(dian)荷, 使(shi)MOSFET導通, 接在(zai)柵(zha)極與源(yuan)極的(de)穩(wen)壓(ya)管(guan)將柵(zha)極電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)限制在(zai)12 V.PNP管(guan)的(de)作(zuo)用(yong)(yong)是釋(shi)放(fang)柵(zha)極電(dian)(dian)(dian)(dian)(dian)(dian)荷, 從而使(shi)MOSFET加(jia)速關斷。在(zai)續流(liu)二(er)極管(guan)兩端加(jia)入RC緩沖(chong)器, 可以(yi)抑制電(dian)(dian)(dian)(dian)(dian)(dian)路寄生參數引起的(de)高頻自激振蕩。在(zai)輸出電(dian)(dian)(dian)(dian)(dian)(dian)路中加(jia)入整(zheng)流(liu)管(guan), 可以(yi)避(bi)免在(zai)電(dian)(dian)(dian)(dian)(dian)(dian)源(yuan)中斷后蓄電(dian)(dian)(dian)(dian)(dian)(dian)池組(zu)對充電(dian)(dian)(dian)(dian)(dian)(dian)器放(fang)電(dian)(dian)(dian)(dian)(dian)(dian)。

1) UC3906內部基準電(dian)(dian)壓的(de)溫度系(xi)(xi)數與鉛酸(suan)蓄(xu)電(dian)(dian)池(chi)的(de)溫度系(xi)(xi)數相同(tong), 從而保證(zheng)了(le)蓄(xu)電(dian)(dian)池(chi)在較寬的(de)溫度范圍(wei)內實現蓄(xu)電(dian)(dian)池(chi)的(de)精確快速充電(dian)(dian), 且(qie)不會過充影(ying)響蓄(xu)電(dian)(dian)池(chi)壽命。

2) UC3823PWM控(kong)(kong)(kong)制(zhi)(zhi)器(qi)在(zai)非常小的(de)脈(mo)沖占空(kong)比到100%的(de)脈(mo)沖占空(kong)比的(de)變化范圍內能夠線性(xing)工作;UC3823PWM控(kong)(kong)(kong)制(zhi)(zhi)器(qi)的(de)帶寬和電路(lu)結構完全滿足平均電流控(kong)(kong)(kong)制(zhi)(zhi)回路(lu)的(de)要求。