PIC單片機的數字式智能鉛酸電池充電器

鉛酸(suan)蓄電(dian)(dian)(dian)池由于其(qi)成(cheng)本低、容量大(da)、安全(quan)可(ke)靠等特(te)點,在通信、電(dian)(dian)(dian)動汽車、軍事、航空航天等各個領域(yu)都(dou)有廣泛的(de)(de)(de)應用(yong)。電(dian)(dian)(dian)池的(de)(de)(de)性能好壞(huai)、使用(yong)壽命的(de)(de)(de)長短直接(jie)影(ying)響(xiang)到電(dian)(dian)(dian)子產品(pin)的(de)(de)(de)使用(yong)壽命和使用(yong)安全(quan);而(er)充電(dian)(dian)(dian)器的(de)(de)(de)好壞(huai)又(you)直接(jie)影(ying)響(xiang)到電(dian)(dian)(dian)池的(de)(de)(de)使用(yong)壽命。因此研究低成(cheng)本又(you)有智能管(guan)理功能的(de)(de)(de)充電(dian)(dian)(dian)器是(shi)有實際應用(yong)價值的(de)(de)(de)課題。

1 目前(qian)智(zhi)能充(chong)電(dian)器的幾(ji)種結構[1]

1.1 基(ji)于專用(yong)芯(xin)片的(de)管(guan)理系統(tong)

現在(zai),UNITRODE 公(gong)司已開發出(chu)系(xi)列電(dian)(dian)(dian)(dian)(dian)池管(guan)理(li)(li)專(zhuan)(zhuan)用(yong)芯片。因為電(dian)(dian)(dian)(dian)(dian)池管(guan)理(li)(li)中采用(yong)最多的就是(shi)控制(zhi)充電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)壓(ya)及(ji)充放電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)流,電(dian)(dian)(dian)(dian)(dian)池管(guan)理(li)(li)芯片正是(shi)抓(zhua)住了這一點,為VRLA 電(dian)(dian)(dian)(dian)(dian)池研(yan)制(zhi)了具有(you)四狀態管(guan)理(li)(li)的專(zhuan)(zhuan)用(yong)控制(zhi)芯片,可以智(zhi)能地實現帶溫度補償的四狀態管(guan)理(li)(li)方案:涓(juan)流充電(dian)(dian)(dian)(dian)(dian)模(mo)(mo)式(shi)、大(da)功率充電(dian)(dian)(dian)(dian)(dian)模(mo)(mo)式(shi)、過充電(dian)(dian)(dian)(dian)(dian)模(mo)(mo)式(shi)和浮充電(dian)(dian)(dian)(dian)(dian)模(mo)(mo)式(shi)。不同的電(dian)(dian)(dian)(dian)(dian)池要有(you)不同的芯片控制(zhi),因此,用(yong)專(zhuan)(zhuan)用(yong)芯片做管(guan)理(li)(li)系(xi)統其靈活性(xing)較差,

1.2 基于監控(kong)測(ce)量(liang)的(de)蓄電池管(guan)理系統

在給電(dian)池充電(dian)的過(guo)程中,涉及到電(dian)池工作(zuo)電(dian)壓(ya)、工作(zuo)電(dian)流、溫(wen)度等參數,這些(xie)都是(shi)表征電(dian)池狀態(tai)的重要參數。采用傳(chuan)感器提取這些(xie)參數,然后再配合故障診斷、遙(yao)控遙(yao)測、自動報警和事故現場處理(li)等功(gong)能,就(jiu)可以組成(cheng)一個電(dian)池管(guan)理(li)系統。如圖1所示。

1.3 與(yu)電(dian)源設備一(yi)起構(gou)成(cheng)的蓄電(dian)池充放(fang)電(dian)管理系(xi)統

在通訊、供電系統中,為了保證電網掉電時蓄電池組能及時補充電能,在規定時間內向負載供電,保證通信或電力合閘系統的正常運轉,通常是將電池組直接掛接在電源模塊輸出端。當電網正常工作時,電池組工作在浮充狀態,起到平滑濾波和保持容量(補充自放電的容量損失)的作用。一旦電網掉電,蓄電池組立即投入工作,當電網恢復,電源模塊立即對電池進行充電。如圖2 所示。

這(zhe)(zhe)樣(yang)(yang)的(de)(de)一個(ge)系統(tong)由于和電(dian)(dian)源模(mo)塊聯系起(qi)來,所以(yi),可(ke)以(yi)從(cong)充放電(dian)(dian)過(guo)程(cheng)上(shang)來優(you)化(hua)電(dian)(dian)池(chi)工作(zuo)狀態,電(dian)(dian)池(chi)充電(dian)(dian)成為可(ke)控的(de)(de)過(guo)程(cheng),建立在這(zhe)(zhe)樣(yang)(yang)一個(ge)系統(tong)上(shang)的(de)(de)監控單元應該具有(you)第一種監控系統(tong)中所有(you)功能(neng),并(bing)且(qie)可(ke)以(yi)和電(dian)(dian)源模(mo)塊直接(jie)“對話”,根(gen)據要(yao)求(qiu)對電(dian)(dian)池(chi)進行管理(li),并(bing)且(qie)可(ke)以(yi)實時監控電(dian)(dian)池(chi)的(de)(de)放電(dian)(dian)狀態,對電(dian)(dian)池(chi)的(de)(de)工作(zuo)進行優(you)化(hua)[2]。因此,電(dian)(dian)池(chi)組的(de)(de)工作(zuo)會更(geng)加(jia)可(ke)靠,可(ke)控性(xing)和智(zhi)能(neng)化(hua)程(cheng)度也(ye)會更(geng)高。但是這(zhe)(zhe)樣(yang)(yang)一個(ge)系統(tong)存在的(de)(de)主要(yao)問(wen)題是:

(1)沒有解決(jue)電(dian)池組(zu)串聯運(yun)行(xing)過程中不均衡 現象的問題,這也是電(dian)池失效(xiao)的重要(yao)原因之一;

(2)一般只完成了(le)電池(chi)生(sheng)產廠家提供(gong)的充電曲線,對于電池(chi)在使用過程中發生(sheng)的其它問題(ti)控制不夠全面,例如(ru)深度(du)放(fang)電后的涓充問題(ti)等。

在將來,充電(dian)器的(de)發展方向是(shi)智能化(hua)、數字(zi)化(hua)、集(ji)成(cheng)化(hua)。智能化(hua)可以使電(dian)池的(de)管(guan)(guan)理做到(dao)全自動,無需(xu)人員監管(guan)(guan),真正做到(dao)免維護。數字(zi)化(hua)和(he)集(ji)成(cheng)化(hua)可以減(jian)(jian)少(shao)管(guan)(guan)理系統(tong)的(de)體積和(he)重量(liang),減(jian)(jian)少(shao)系統(tong)的(de)復(fu)雜度(du)。

2 目(mu)前幾種充電(dian)方(fang)式[3]

鉛酸蓄電池的充(chong)(chong)電方法目前(qian)主要(yao)有(you)恒(heng)流、恒(heng)壓(ya)、恒(heng)壓(ya)限流、脈沖充(chong)(chong)電、Reflex充(chong)(chong)電法。

2.1 恒(heng)流充(chong)電

恒流(liu)充(chong)電(dian)(dian)方式是(shi)(shi)一種簡單的充(chong)電(dian)(dian)方法。但是(shi)(shi),恒流(liu)充(chong)電(dian)(dian)有(you)其局限(xian)性(xing):對電(dian)(dian)池過充(chong)電(dian)(dian)就會(hui)造(zao)成電(dian)(dian)池壽命(ming)的縮短,而過小電(dian)(dian)流(liu)又會(hui)延長充(chong)電(dian)(dian)時間。

2.2 恒壓充電(dian)

恒壓充(chong)(chong)(chong)電(dian)(dian)用(yong)簡單(dan)的(de)控制方法(fa)很(hen)容(rong)易(yi)就能實現。在充(chong)(chong)(chong)電(dian)(dian)的(de)初(chu)始階段,由于電(dian)(dian)池的(de)電(dian)(dian)壓很(hen)低(di)而(er)造成充(chong)(chong)(chong)電(dian)(dian)電(dian)(dian)流很(hen)大(da),這對電(dian)(dian)池會(hui)造成損害。當(dang)電(dian)(dian)池電(dian)(dian)壓達到一(yi)定值之(zhi)后(hou),電(dian)(dian)流就會(hui)隨之(zhi)減(jian)小。這種充(chong)(chong)(chong)電(dian)(dian)方法(fa)的(de)缺點(dian)就是會(hui)造成溫度上升和電(dian)(dian)池的(de)壽命減(jian)少,并且在開始時(shi)電(dian)(dian)流很(hen)大(da),而(er)后(hou)來快充(chong)(chong)(chong)滿時(shi)電(dian)(dian)流又(you)很(hen)小,就無法(fa)充(chong)(chong)(chong)分利用(yong)充(chong)(chong)(chong)電(dian)(dian)器的(de)容(rong)量。

2.3 恒壓(ya)限流(liu)法

恒(heng)壓(ya)限流(liu)法實(shi)際上(shang)(shang)是(shi)將恒(heng)壓(ya)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)和(he)恒(heng)流(liu)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)相結合,又可(ke)稱為混(hun)合充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)法。在充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)開始階段,由于電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)過(guo)低,為避免電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)過(guo)大而損壞電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi),就采用恒(heng)流(liu)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)法來限制(zhi)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)。但電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)達到(dao)預定值時(shi),進(jin)入恒(heng)壓(ya)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)方(fang)式(shi)(shi)。恒(heng)壓(ya)限流(liu)方(fang)式(shi)(shi)是(shi)大多數(shu)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)廠商(shang)推薦的(de)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)方(fang)式(shi)(shi)。由于蓄電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)較低,充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)后(hou)期電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)很(hen)小,因此(ci)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)解液(ye)中產生的(de)氣泡很(hen)少,可(ke)以(yi)(yi)節省電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)能、降低蓄電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)的(de)溫升,避免損壞電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)的(de)極板(ban)。恒(heng)壓(ya)限流(liu)方(fang)式(shi)(shi)是(shi)一種很(hen)有(you)效的(de)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)方(fang)式(shi)(shi),加上(shang)(shang)過(guo)充判斷、浮充控制(zhi)、溫度補償等就可(ke)以(yi)(yi)形(xing)成一個簡單的(de)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)管理系統,蓄電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)可(ke)以(yi)(yi)在這個系統下更好地工(gong)作。

2.4 脈沖充電[4]

在充(chong)(chong)電(dian)(dian)過程中,只要充(chong)(chong)電(dian)(dian)電(dian)(dian)流(liu)不超過蓄電(dian)(dian)池(chi)(chi)可(ke)接受(shou)的(de)(de)(de)電(dian)(dian)流(liu),蓄電(dian)(dian)池(chi)(chi)內部就(jiu)不會產生大(da)量的(de)(de)(de)氣泡。蓄電(dian)(dian)池(chi)(chi)中產生的(de)(de)(de)極(ji)化(hua)現象會阻礙充(chong)(chong)電(dian)(dian),并且使出氣率(lv)和溫升顯著升高(gao)。因此(ci),極(ji)化(hua)電(dian)(dian)壓(ya)是(shi)影響充(chong)(chong)電(dian)(dian)速度的(de)(de)(de)重要因素。用(yong)周(zhou)期性(xing)的(de)(de)(de)脈動電(dian)(dian)流(liu)給電(dian)(dian)池(chi)(chi)充(chong)(chong)電(dian)(dian)可(ke)以(yi)使電(dian)(dian)池(chi)(chi)有時(shi)間恢復其原來狀態,減小極(ji)化(hua)現象的(de)(de)(de)影響,解決快速充(chong)(chong)電(dian)(dian)面臨的(de)(de)(de)難題。但是(shi)目前(qian)這種(zhong)充(chong)(chong)電(dian)(dian)方式還(huan)在研究階(jie)段,對于采用(yong)多(duo)大(da)的(de)(de)(de)脈沖周(zhou)期,占空比又(you)是(shi)多(duo)少之類的(de)(de)(de)具(ju)體問(wen)題還(huan)沒有一個定(ding)論。

2.5 ReflexTM充電方式

Reflex 充電方法是脈沖電流法的改進:一個周期是由一個正脈沖后加一個負脈沖,然后才是空閑時段。這樣就強制消除電池的極化現象,使得電池充電時可以更快而又不損害電池的使用壽命。這種充電方式與脈沖充電方式一樣,仍然處于研究階段。

. 3 數字式智能充(chong)電器的設計

3.1 系統結(jie)構和(he)充電方案的設計

本文中設計的(de)系(xi)統是(shi)一個針對12 V/(200~500Ah)的(de)鉛酸蓄電池智能(neng)充電系(xi)統。采用(yong)半橋作為主功率拓撲,開關頻率取(qu)80kHz左右。

對(dui)于一個智能管理系(xi)(xi)統,控制(zhi)模(mo)塊無(wu)異于它的(de)(de)大(da)腦(nao)。充電器的(de)(de)所有動(dong)作都是由它來決(jue)定和控制(zhi)的(de)(de),所以(yi)控制(zhi)模(mo)塊的(de)(de)選擇關系(xi)(xi)到整(zheng)個系(xi)(xi)統的(de)(de)優(you)劣。由于系(xi)(xi)統需要多(duo)個A/D 轉換器,但不(bu)需要擴(kuo)展(zhan)存儲器也不(bu)需要通訊,根據(ju)以(yi)上特點(dian)我(wo)們(men)選擇了MICROCHIP 公司的(de)(de)PIC 系(xi)(xi)列(lie)PIC16C73 單片機。

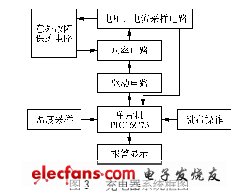

圖3 所示為智能充電器的(de)系(xi)(xi)統(tong)(tong)框圖(tu)。單片機是智能充(chong)電(dian)(dian)器的(de)核心(xin)部件(jian),它根據電(dian)(dian)流(liu)、電(dian)(dian)壓采樣(yang)以及溫度采樣(yang)做(zuo)出溫度補(bu)償后的(de)PWM波形輸出,經過驅動電(dian)(dian)路(lu)(lu)提供給功率(lv)電(dian)(dian)路(lu)(lu),并且決定(ding)了智能充(chong)電(dian)(dian)器的(de)工(gong)作狀(zhuang)態,可(ke)(ke)以在必要(yao)的(de)情況下做(zuo)出保護(hu)動作。意外故障保護(hu)電(dian)(dian)路(lu)(lu)可(ke)(ke)以在單片機失效(xiao)的(de)情況下對(dui)電(dian)(dian)路(lu)(lu)進行(xing)強(qiang)制保護(hu),起(qi)到雙重保險的(de)作用(yong)。報警顯示部分用(yong)若干個LED表示系(xi)(xi)統(tong)(tong)的(de)運行(xing)狀(zhuang)態,簡單有效(xiao)。

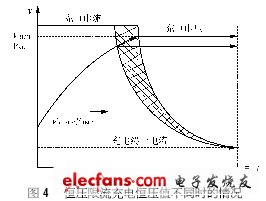

充(chong)(chong)電(dian)(dian)方式采用恒壓(ya)限(xian)流(liu)法。恒壓(ya)限(xian)流(liu)充(chong)(chong)電(dian)(dian)模式分兩(liang)個(ge)階(jie)(jie)段(duan)(duan),第(di)一階(jie)(jie)段(duan)(duan)是恒流(liu)階(jie)(jie)段(duan)(duan),即(ji)系(xi)統(tong)給(gei)定電(dian)(dian)流(liu)值(zhi),給(gei)電(dian)(dian)池以恒定電(dian)(dian)流(liu)充(chong)(chong)電(dian)(dian),當(dang)電(dian)(dian)池的(de)(de)電(dian)(dian)壓(ya)達到系(xi)統(tong)給(gei)定的(de)(de)轉化值(zhi),就轉為第(di)二階(jie)(jie)段(duan)(duan)―――恒壓(ya)階(jie)(jie)段(duan)(duan)。恒壓(ya)轉化值(zhi)會影響充(chong)(chong)入電(dian)(dian)量的(de)(de)多少(shao)。

由圖4 可知,當恒(heng)壓(ya)(ya)轉化值(zhi)(zhi)(Vref)設(she)置的(de)較低時,充(chong)(chong)入(ru)的(de)電(dian)(dian)量(liang)不足(圖中陰影部分就(jiu)是少(shao)充(chong)(chong)入(ru)的(de)容量(liang)),沒有(you)充(chong)(chong)分利用電(dian)(dian)池的(de)容量(liang),長期(qi)工作(zuo),會引起(qi)電(dian)(dian)池容量(liang)丟失,這就(jiu)要求把恒(heng)壓(ya)(ya)轉化值(zhi)(zhi)設(she)高(gao)。但是恒(heng)壓(ya)(ya)值(zhi)(zhi)較高(gao),容易在充(chong)(chong)電(dian)(dian)末期(qi)引起(qi)過充(chong)(chong)電(dian)(dian),這同樣會導致(zhi)電(dian)(dian)池容量(liang)丟失。

為(wei)了解決這(zhe)(zhe)個(ge)矛(mao)盾,系統引進了第三(san)個(ge)階段(duan)―――浮充(chong)(chong)階段(duan),這(zhe)(zhe)樣(yang)就可(ke)(ke)以(yi)把恒(heng)壓轉化(hua)值設置(zhi)的(de)比普通恒(heng)壓限流模式高,這(zhe)(zhe)樣(yang)可(ke)(ke)以(yi)保證充(chong)(chong)入足夠的(de)電量(liang),在充(chong)(chong)電末期轉入浮充(chong)(chong)階段(duan),用稍低的(de)電壓浮充(chong)(chong)充(chong)(chong)電,從(cong)而保證不會過充(chong)(chong)電。

三階段(duan)充電(dian)(dian)(dian)方(fang)(fang)法保證了充電(dian)(dian)(dian)末期不過充,同時又能達到滿充的(de)目(mu)的(de),是一種成本較低(di)的(de)通用(yong)蓄電(dian)(dian)(dian)池充電(dian)(dian)(dian)解決方(fang)(fang)案。

3.2 軟件系統的設計

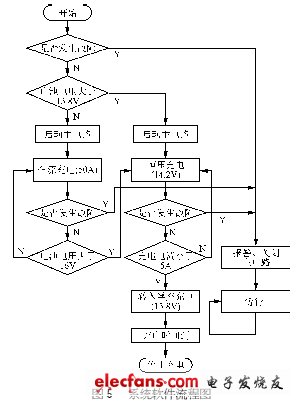

圖5 為系統軟(ruan)件的程(cheng)序(xu)流程(cheng)圖。根據電池的端電壓決(jue)定充(chong)電器工作在何種充(chong)電狀態(tai)。

我(wo)們做的(de)(de)(de)是(shi)全數字化的(de)(de)(de)改良型PI 調(diao)節(jie)環(huan),由于(yu)PI 調(diao)節(jie)的(de)(de)(de)積(ji)分環(huan)在(zai)前期(qi)對誤(wu)差進(jin)行積(ji)累,為了不讓積(ji)累的(de)(de)(de)誤(wu)差影響系統(tong)的(de)(de)(de)穩定性,所(suo)以我(wo)們在(zai)誤(wu)差等(deng)于(yu)0 時(shi),對原有積(ji)累的(de)(de)(de)誤(wu)差清(qing)零。當誤(wu)差等(deng)于(yu)±1 時(shi),只進(jin)行積(ji)分運算,減慢調(diao)整(zheng)速度,避免產生振蕩。

鉛酸蓄電池的(de)充(chong)電電壓需要根據環境(jing)溫度進行調(diao)整,以-4 mV/℃的(de)補(bu)償(chang)系(xi)數來調(diao)整。因此我們加入了溫度補(bu)償(chang)的(de)功能。

4 實驗結果

圖6 為用電子負載模擬電池(chi)三階段(duan)充(chong)電過程的(de)波(bo)形圖。從(cong)圖6 中我們可以(yi)看(kan)出智能充(chong)電系統能夠方便地實現各(ge)個(ge)充(chong)電狀(zhuang)態的(de)轉換。

5 結語

用PIC 單(dan)片機可(ke)(ke)以(yi)實(shi)(shi)現(xian)全數字化(hua)的(de)(de)電(dian)池充電(dian)管(guan)(guan)理,結構(gou)簡單(dan),成本(ben)較(jiao)低,并且(qie)具(ju)有很高的(de)(de)靈活性,通(tong)過改(gai)變(bian)軟(ruan)件(jian)內設置的(de)(de)恒(heng)流(liu)參考值(zhi)和(he)恒(heng)壓參考值(zhi)就(jiu)可(ke)(ke)以(yi)改(gai)變(bian)系統的(de)(de)恒(heng)流(liu)電(dian)流(liu)和(he)恒(heng)壓電(dian)壓值(zhi),使得系統在不改(gai)變(bian)系統硬件(jian)設計的(de)(de)情況下實(shi)(shi)現(xian)給多(duo)種(zhong)不同(tong)容量的(de)(de)鉛酸蓄電(dian)池充電(dian)。另外(wai)可(ke)(ke)以(yi)實(shi)(shi)現(xian)有效的(de)(de)電(dian)池充電(dian)管(guan)(guan)理和(he)保護功能(neng)(neng),達到智(zhi)能(neng)(neng)化(hua)控制。